Drill bits for drilling large diameter piles in bridge foundations

A bridge foundation and large-diameter technology, applied in the direction of drill bits, drilling equipment, earthwork drilling and mining, etc., can solve the problems of limited suction force of a single slag suction port, affecting the drilling efficiency of the drill bit, repeated crushing of rock slag, etc., to reduce repeated crushing , Improve the rock-breaking ability and slag discharge efficiency, and improve the effect of the stress condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

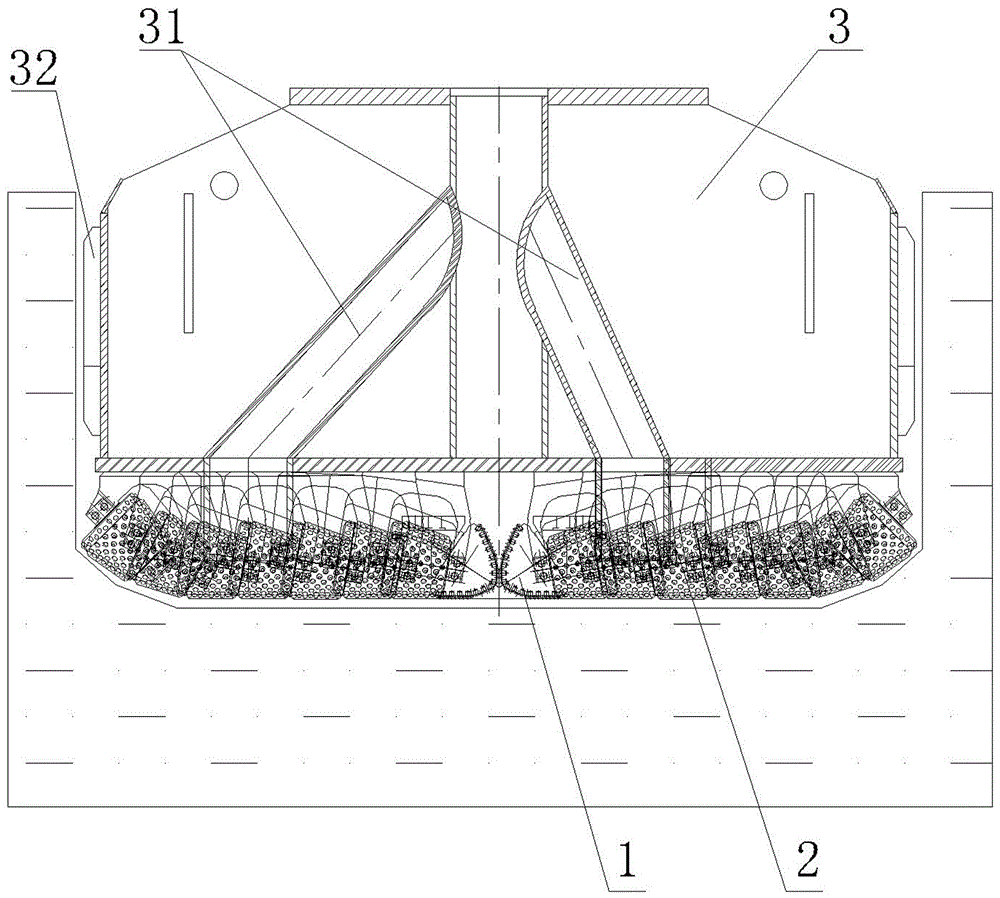

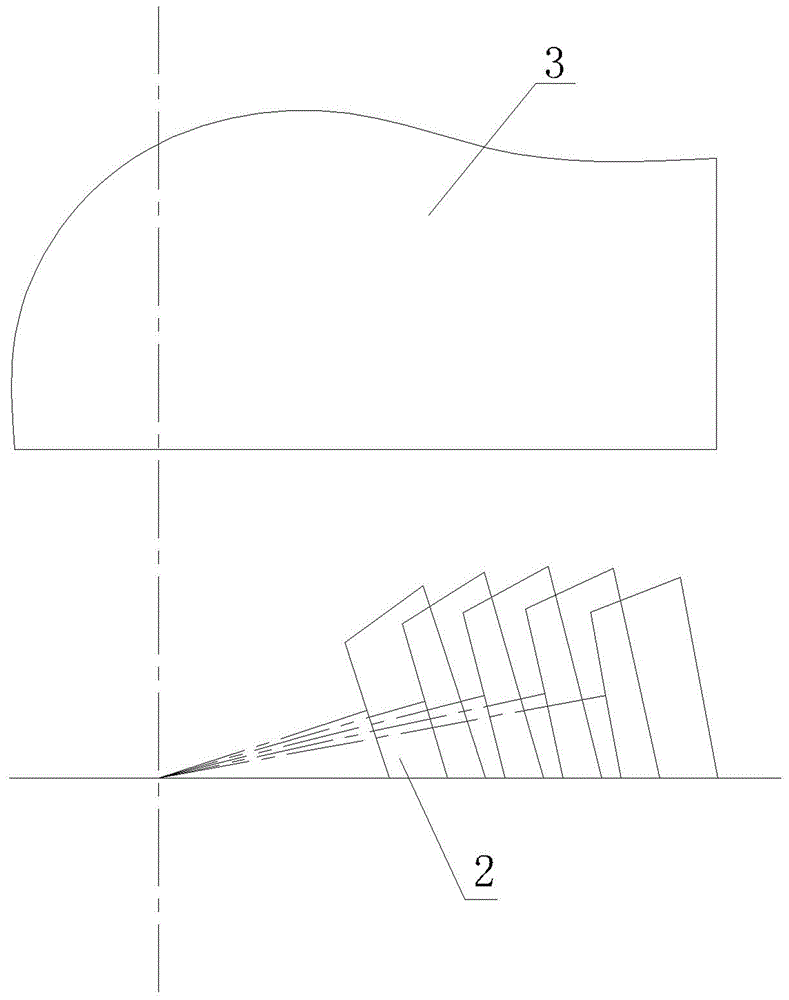

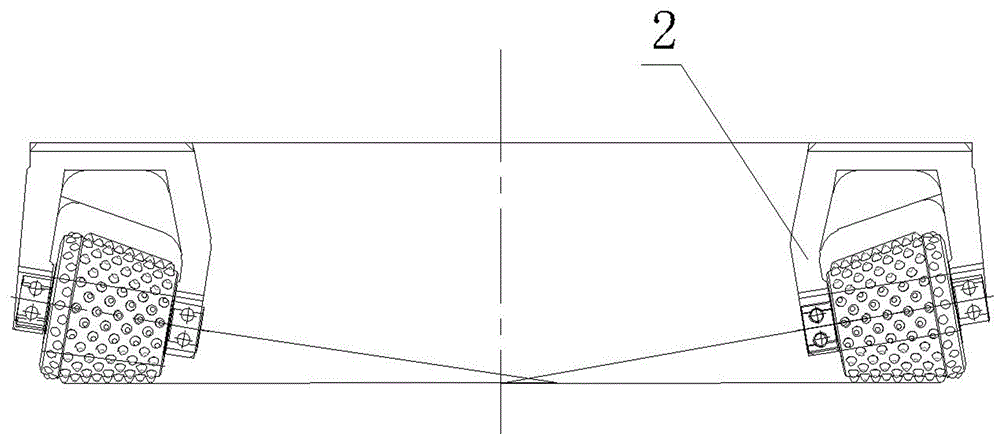

[0027] From Figure 1 to Figure 3 It can be seen that the drill bit used for drilling large-diameter piles of bridge foundations according to the present invention includes two single-support ball-tooth hobs 1, several hobs and hob tool holder assemblies 2 and cutterhead body 3, each hob The hob on the hob and hob tool holder assembly 2 adopts a ball-tooth shape, and two slag suction ports 31 are provided on the cutter head body 3. 2. Indirect welding under the cutterhead body 3 by means of electric welding through the backing plates corresponding to each cutter holder to form a flat-bottomed rolling section. The angle between them decreases in turn along the radial direction of the cutter body 3 from its axis to the surroundings. The axis of the hob cutter shaft and the cutter body The intersection points of the busbars intersect on the central axis of the cutter head body 3 to form a pure rolling rock breaking.

Embodiment 2

[0029] From Figure 4 to Figure 6 It can be seen that the drill bit used for drilling large-diameter piles of bridge foundations according to the present invention includes two single-support ball-tooth hobs 1, several hobs and hob tool holder assemblies 2 and cutterhead body 3, each hob The hob on the hob and hob tool holder assembly 2 adopts a welding tooth shape, and two slag suction ports 31 are provided on the cutter head body 3. 2. Indirect welding under the cutterhead body 3 by means of electric welding through the backing plates corresponding to each cutter holder to form a flat-bottomed rolling section. The angle between them decreases in turn along the radial direction of the cutter body 3 from its axis to the surroundings. The axis of the hob cutter shaft and the cutter body The intersection points of the busbars intersect on the central axis of the cutter head body 3 to form a pure rolling rock breaking.

Embodiment 3

[0031] From Figure 7 to Figure 9 It can be seen that the drill bit used for drilling large-diameter piles of bridge foundations according to the present invention includes two single-support ball-tooth hobs 1, several hobs and hob tool holder assemblies 2 and cutterhead body 3, each hob and the hob on the hob tool holder assembly 2 adopts a button shape, and two slag suction ports 31 are arranged on the cutter head body 3, and several backing plates 33 are arranged obliquely at the bottom of the cutter head body 3, each The single fulcrum ball tooth hob 1 and the hob and hob tool holder assembly 2 are welded under the corresponding backing plate 32, and the rolling section of each hob and hob cutter holder assembly 2 intersects with the axis of the cutter head body 3 to form a A conical rolling section, the angle between the axis of the hob cutter shaft on each hob and the hob holder assembly 2 and the generatrix of the cutter body decreases sequentially along the axis of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com