Preparation method of Nd1.85Ce0.15CuO4-detal superconducting target with preferred orientation

A nd1.85ce0.14cuo4- technology with preferential orientation, applied in the field of superconducting powder, can solve the problems of high energy consumption and inability to synthesize, and achieve the effect of reducing energy consumption and realizing preferential growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

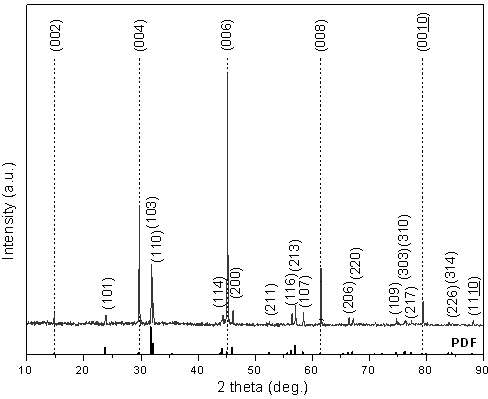

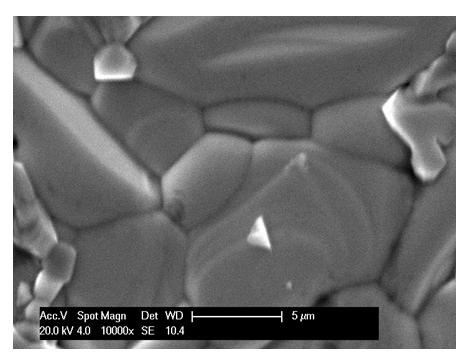

[0021] Implementation mode one: if figure 1 As shown, this embodiment has a preferred orientation of Nd 1.85 Ce 0.15 CuO 4-δ The preparation method of the superconducting target is as follows:

[0022] (1) Nd(NO 3 ) 3 ·nH 2 O, Ce(NO 3 ) 3 ·6H 2 O, Cu(NO 3 ) 2 ·3H 2 O and citric acid are weighed according to the molar ratio of Nd: Ce: Cu: EDTA being 1.85: 0.15: 1: 6;

[0023] (2) According to the liquid-solid ratio (L / Kg) of 20:1, put the citric acid prepared in step (1) in deionized water, citric acid solution;

[0024] (3) Add the Nd(NO 3 ) 3 ·nH 2 O, Ce(NO 3 ) 3 ·6H 2 O and Cu(NO 3 ) 2 ·3H 2 O, obtain mixed solution;

[0025] (4) Heat the mixture obtained in step (3) to reflux at 60°C for 4 hours to obtain a sol, then heat, evaporate and concentrate for 6 hours to obtain a gel, and dry the gel in an oven at 70°C under normal pressure to obtain a dry gel;

[0026] (5) Calcinate the xerogel obtained in step (4) at 700°C for 8 hours in an air atmosphere t...

Embodiment approach 2

[0029] Embodiment 2: This embodiment has Nd with preferred orientation 1.85 Ce 0.15 CuO 4-δ The preparation method of the superconducting target is as follows:

[0030] (1) Nd(NO 3 ) 3 ·nH 2 O, Ce(NO 3 ) 3 ·6H 2 O, Cu(NO 3 ) 2 ·3H 2 O and citric acid are prepared according to the molar ratio of Nd: Ce: Cu: EDTA of 1.85: 0.15: 1: 3;

[0031] (2) According to the liquid-solid ratio (L / Kg) of 5:1, prepare the citric acid prepared in step (1) into an aqueous solution;

[0032] (3) Add the Nd(NO 3 ) 3 ·nH 2 O, Ce(NO 3 ) 3 ·6H 2 O and Cu(NO 3 ) 2 ·3H 2 O, obtain mixed solution;

[0033] (4) Heat the mixed solution at 40°C to reflux to obtain a sol, then heat and evaporate to concentrate to obtain a gel, and dry the gel to obtain a xerogel; the time for heating and reflux is 4 hours, and the time for evaporation and concentration is 7 hours; the drying temperature is 150°C, the drying condition is normal pressure;

[0034] (5) Calcining the xerogel at 700°C to ...

Embodiment approach 3

[0036] Embodiment 3: This embodiment has the preferred orientation of Nd 1.85 Ce 0.15 CuO 4-δ The preparation method of the superconducting target is as follows:

[0037] (1) Nd(NO 3 ) 3 ·nH 2 O, Ce(NO 3 ) 3 ·6H 2 O, Cu(NO 3 ) 2 ·3H 2 O and citric acid are prepared according to the molar ratio of Nd: Ce: Cu: EDTA of 1.85: 0.15: 1: 10;

[0038] (2) According to the liquid-solid ratio (L / Kg) of 40:1, prepare the citric acid prepared in step (1) into an aqueous solution;

[0039] (3) Add the Nd(NO 3 ) 3 ·nH 2 O, Ce(NO 3 ) 3 ·6H 2 O and Cu(NO 3 ) 2 ·3H 2 O, obtain mixed solution;

[0040] (4) Heat the mixed solution to reflux at 70°C to obtain a sol, then heat, evaporate and concentrate to obtain a gel, and dry the gel to obtain a xerogel; the time for heating and reflux is 1 hour, and the time for evaporation and concentration is 3 hours; the drying temperature is 50°C, the drying condition is normal pressure;

[0041] (5) Calcining the xerogel at 700°C to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com