Polydimethylsilanediol synthesis method

A technology of polydimethylsilanediol and synthesis method, which is applied in the direction of silicon organic compounds, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve environmental pollution and other problems, and achieve the difficulty of processing The effect of large size, elimination of pollution sources, and high treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

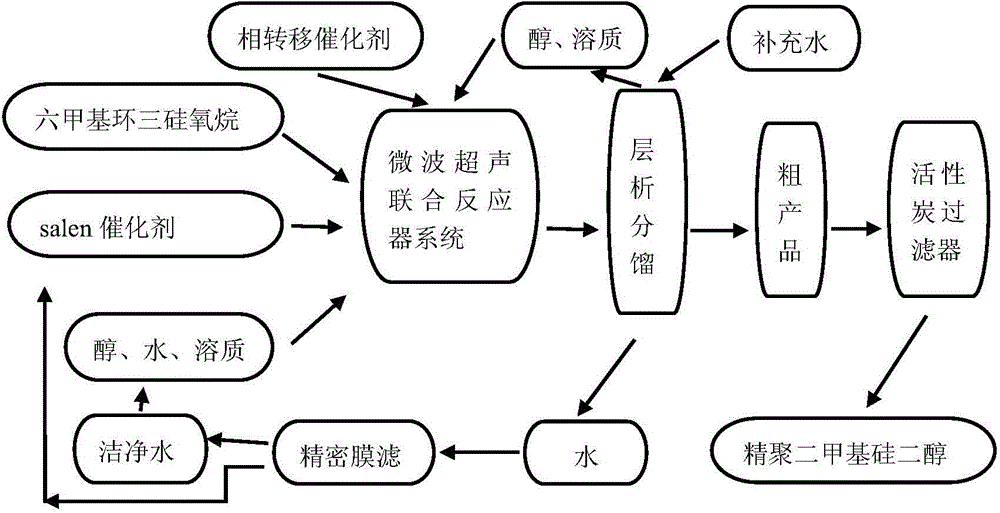

Method used

Image

Examples

Embodiment 1

[0022] (1) Raw materials: Hexamethylcyclotrisiloxane (D3) content ≥ 99.50%, about 140 kg;

[0023] 114 liters of deionized water is about 114 kg;

[0024] Industrially pure methanol, 21 liters, about 18 kg;

[0025] Cosolvent is selected 36 liters of acetone, about 28 kilograms;

[0026] Imidazolium salt analytical purity Purity ≥ 99% 15g;

[0027] Activated carbon industrial grade 100g;

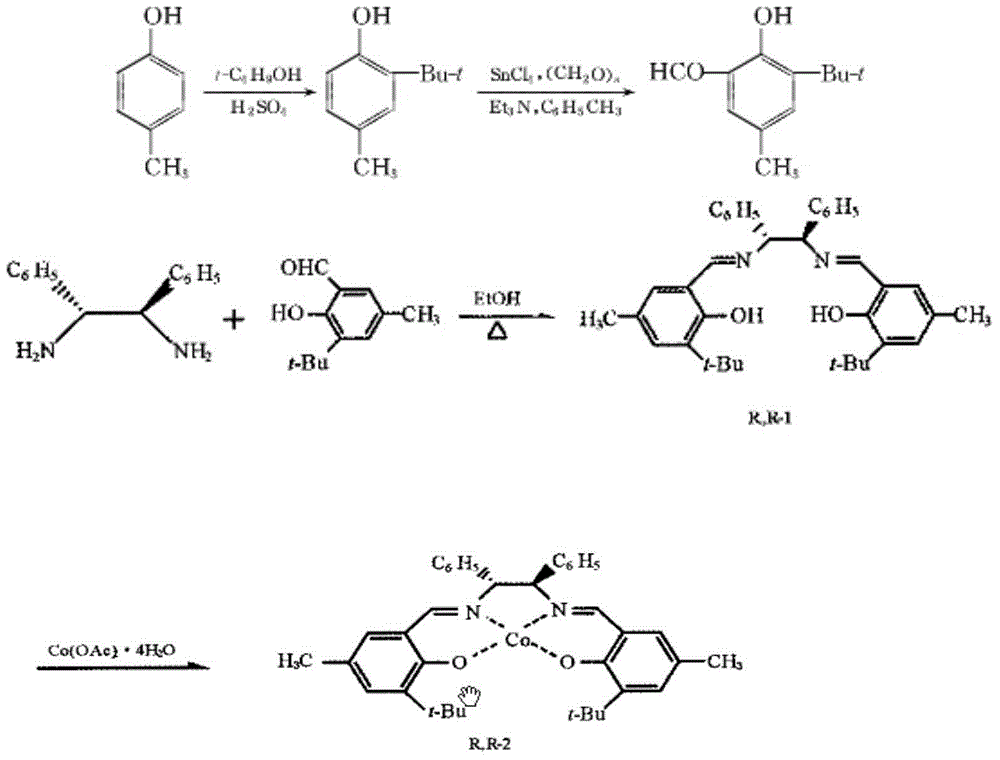

[0028] Loaded salen catalyst 500g, self-made: condense (R,R)1,2-diphenylethylenediamine (DPEDA) 70g with 2-hydroxy-5-methyl-3-tert-butylbenzaldehyde 10g, temperature 110 ℃, to obtain chiral Salen, and then with Co(OAc)·4H 2 O35g is complexed and oxidized to obtain the Salen Co(III) chiral catalyst. Dissolve the salen catalyst in 500ML of ethanol and 500g of alumina, mix well and remove the ethanol to obtain the finished catalyst supported product. Catalyst synthesis route is as follows:

[0029]

[0030] (2) Production equipment

[0031] 1 set of 500L microwave and ultrasonic combine...

Embodiment 2

[0038] Concrete method is the same as embodiment 1, and difference is:

[0039] The first step is the synthesis reaction. 120kg of hexamethylcyclotrisiloxane, 105kg of deionized water, 18kg of methanol and 24kg of acetone are put into the microwave ultrasonic combined reactor system, and 500g of supported chiral catalyst (salen catalyst) is added, and the phase transfer Catalyst imidazolium salt 15g;

[0040] Second step is fractional distillation chromatography, adds 28kg water to the material that the first step reaction is completed;

[0041] In the third step, 100 g of activated carbon (0.67‰) was added to the obtained crude polydimethylsilanediol. Finally obtain about 129 kilograms of polydimethylsilanediol product.

Embodiment 3

[0043] Concrete method is the same as embodiment 1, and difference is:

[0044] The first step is the synthesis reaction. 145kg of hexamethylcyclotrisiloxane, 120kg of deionized water, 24kg of methanol and 36kg of acetone are put into the microwave ultrasonic combined reactor system, and 500g of supported chiral catalyst (salen catalyst) is added, and the phase transfer Catalyst imidazolium salt 15g;

[0045] Second step is fractional distillation chromatography, adds 30kg water to the material that the first step reaction is completed;

[0046] In the third step, 100 g of activated carbon (0.67‰) was added to the obtained crude polydimethylsilanediol. Finally obtain about 156 kilograms of polydimethylsilanediol product.

[0047] The yield of the polydimethylsilanediol product produced by the method of the present invention can reach more than 98%, and the product viscosity (25°C): 30-40mm 2 / s; ring body content: 15-20%; hydroxyl value: 9.0-11.5%, appearance: colorless and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com