Double-arc slanted-off finned tube non-contact thermal resistance heat transfer element

A technology of heat transfer elements and finned tubes, applied in the field of heat exchange, can solve the problems of complex manufacturing and processing technology, large contact thermal resistance, fracture, etc., and achieve convective heat transfer, increased heat dissipation area, and good heat transfer performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

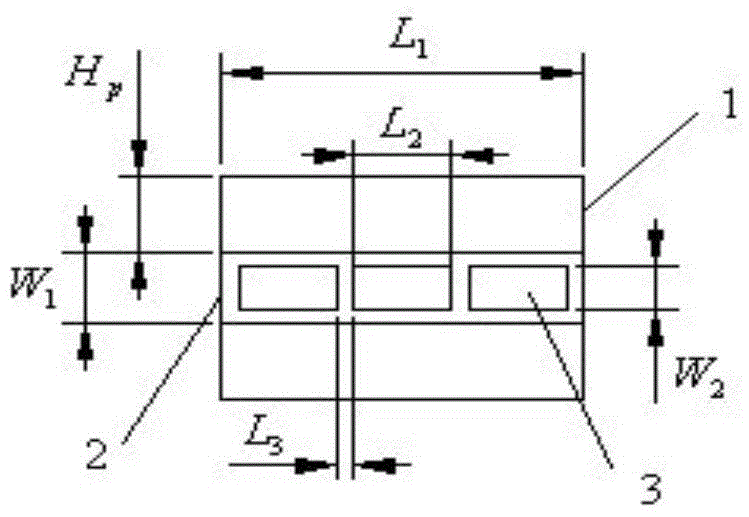

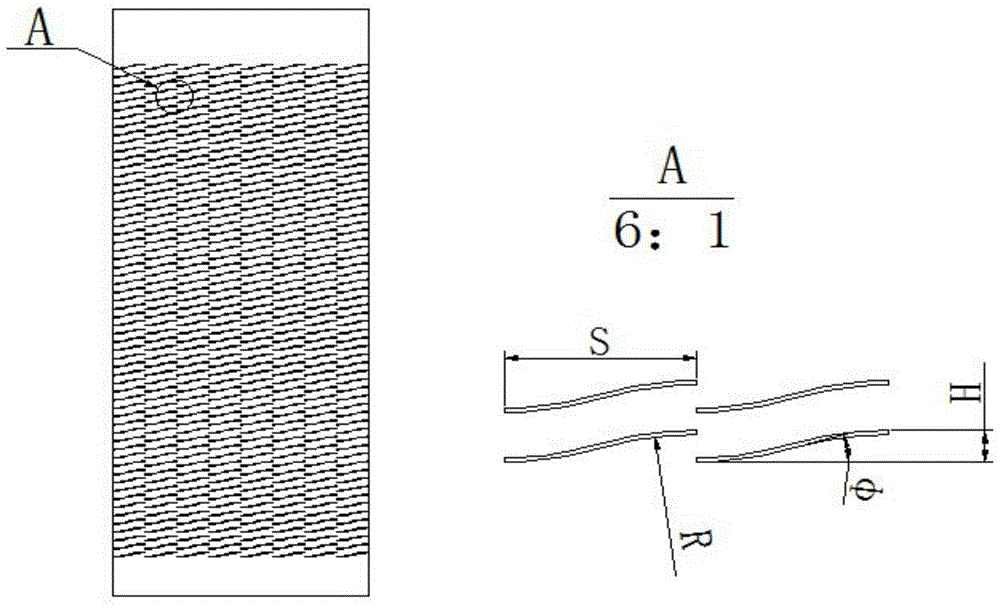

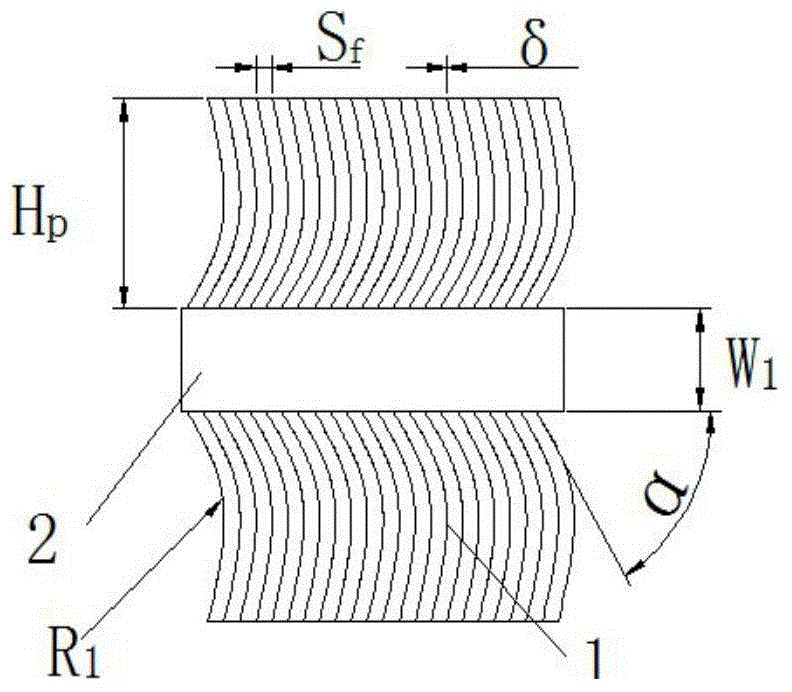

[0013] Such as figure 1 , 2 As shown in , 3, the non-contact thermal resistance heat transfer element of the double-arc slanted-off finned tube designed in the present invention is composed of radiating fins 1 and heat transfer flat tubes 2 . The inclined broken fins 1 are directly shoveled on the upper and lower sides of the heat transfer flat tube 2, and the radiating fin 1 and the heat transfer flat tube 2 are integrated, and in the process of shoveling, the radiating fin 1 and the heat transfer flat tube 2 are integrated. The heat transfer flat tube 2 is naturally α (0°° ), and at the same time, it is arc-shaped with a radius of R1, and the distance between the cooling fins 1 is S f , the fin thickness of cooling fin 1 is δ, and the height is H p (see attached image 3 ); the length of the small unit of the inclined broken fin of the cooling fin 1 is S, the height is H, the inclination angle is φ, and two tangent radiuses are R arcs (see attached figure 2 ); the secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com