Intelligent large-torque starting method of wound-type motor

A starting method, winding technology, applied in the direction of motor generator/starter, single multi-phase induction motor starter, etc., to achieve the effect of high motor energy conversion rate, large starting torque and high power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

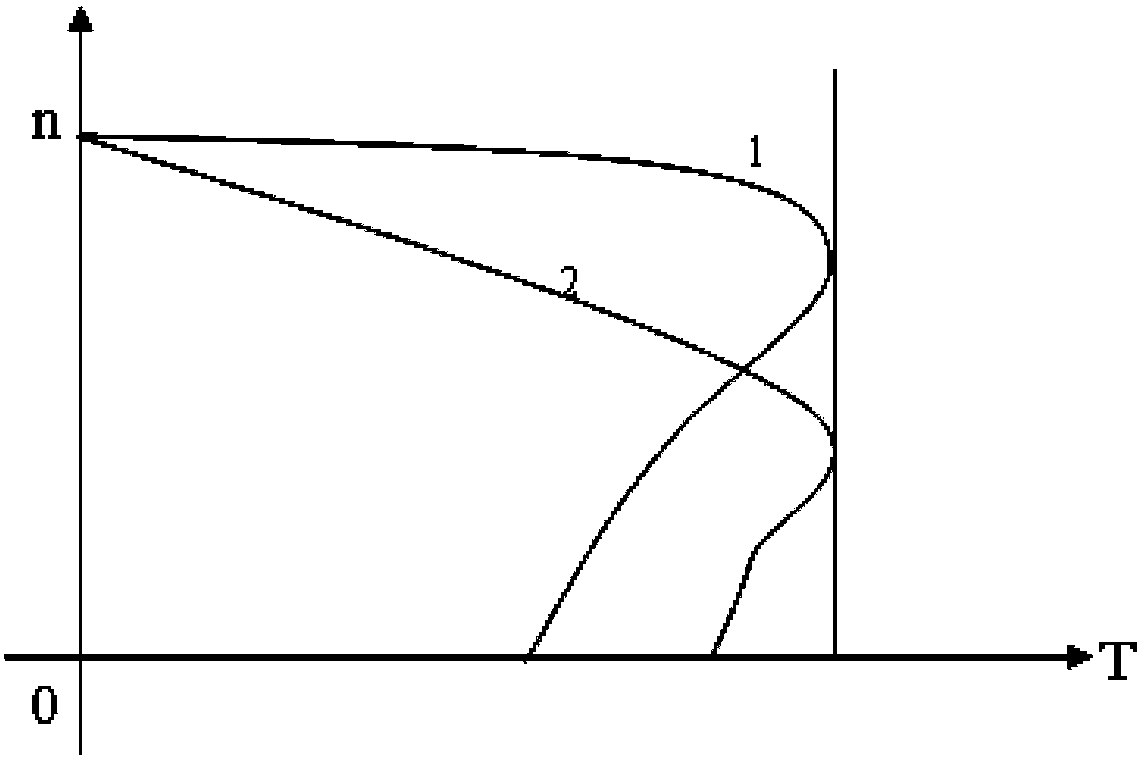

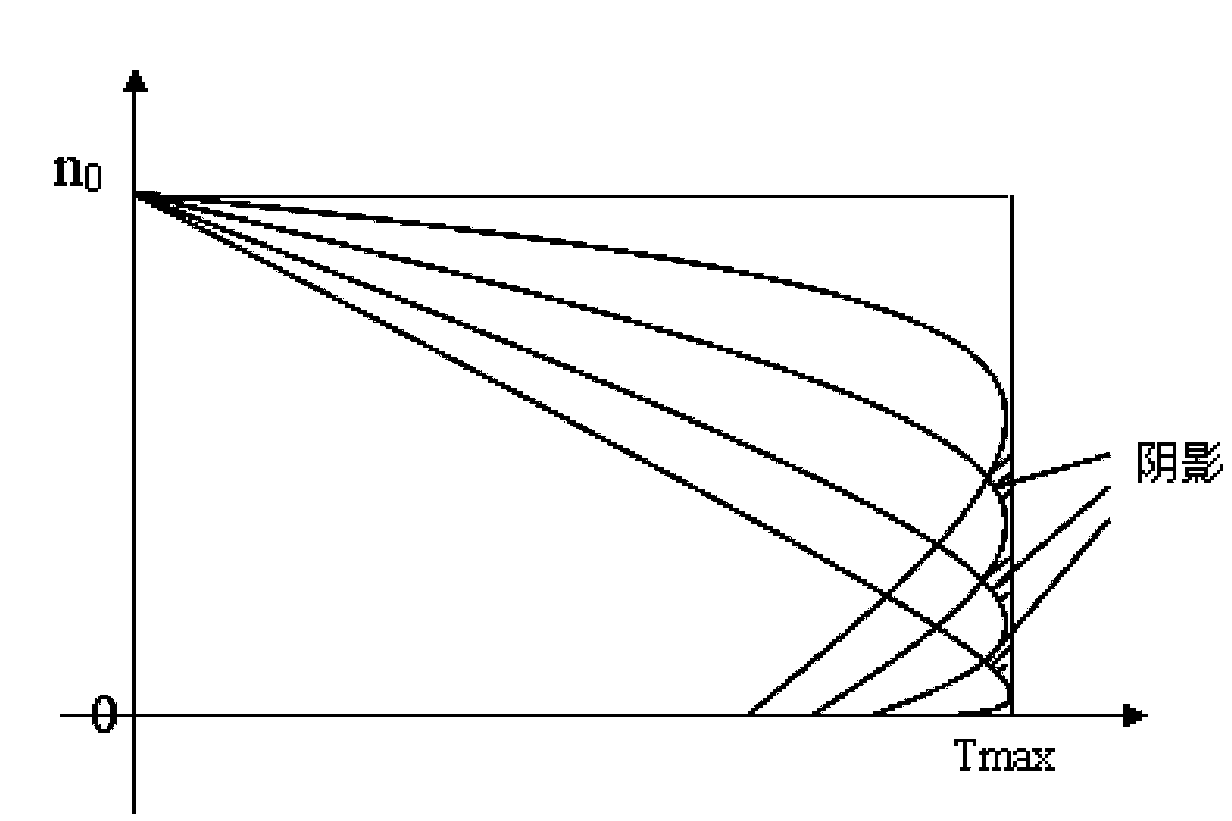

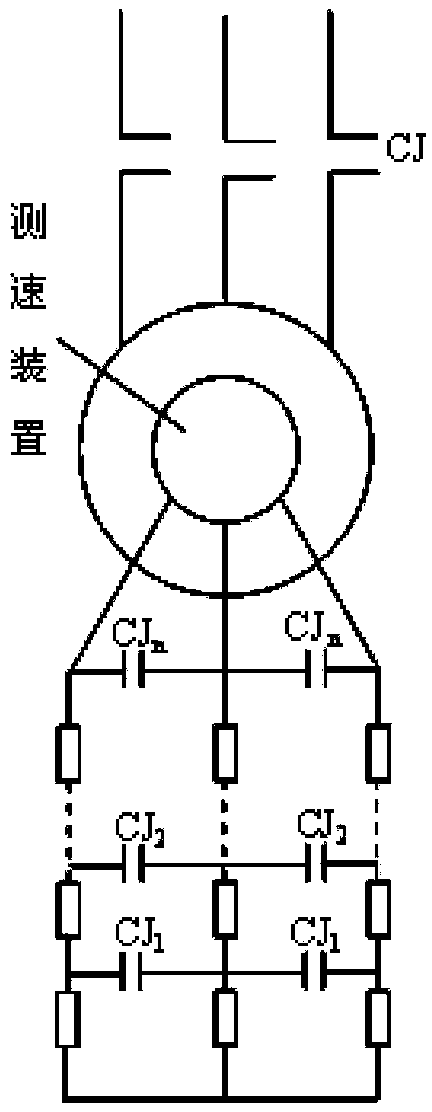

[0023] The mechanical characteristics of the motor for speed regulation by using the rotor series resistance of the wound asynchronous motor, the mechanical characteristics of the motor are shown in the figure figure 1 As shown, curve 1 in the figure is the inherent characteristics of the motor, that is, the rotor winding is directly short-circuited when starting, without any external resistance or the mechanical characteristics when the external resistance is equal to zero; curve 2 is the artificial mechanical characteristics of the motor, that is, in the winding type asynchronous motor The mechanical characteristics of the rotor circuit after a certain value of resistance is connected in series, also called artificial mechanical characteristics, referred to as artificial characteristics. from figure 1 It can be seen from the figure that re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com