Portable micro-plasma sterilizer

A micro-plasma and sterilizer technology, which is applied in disinfection, food science, sanitary equipment for toilets, etc., can solve the problems of high manufacturing cost and operating cost, and achieve the effect of solving the manufacturing cost and sterilization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

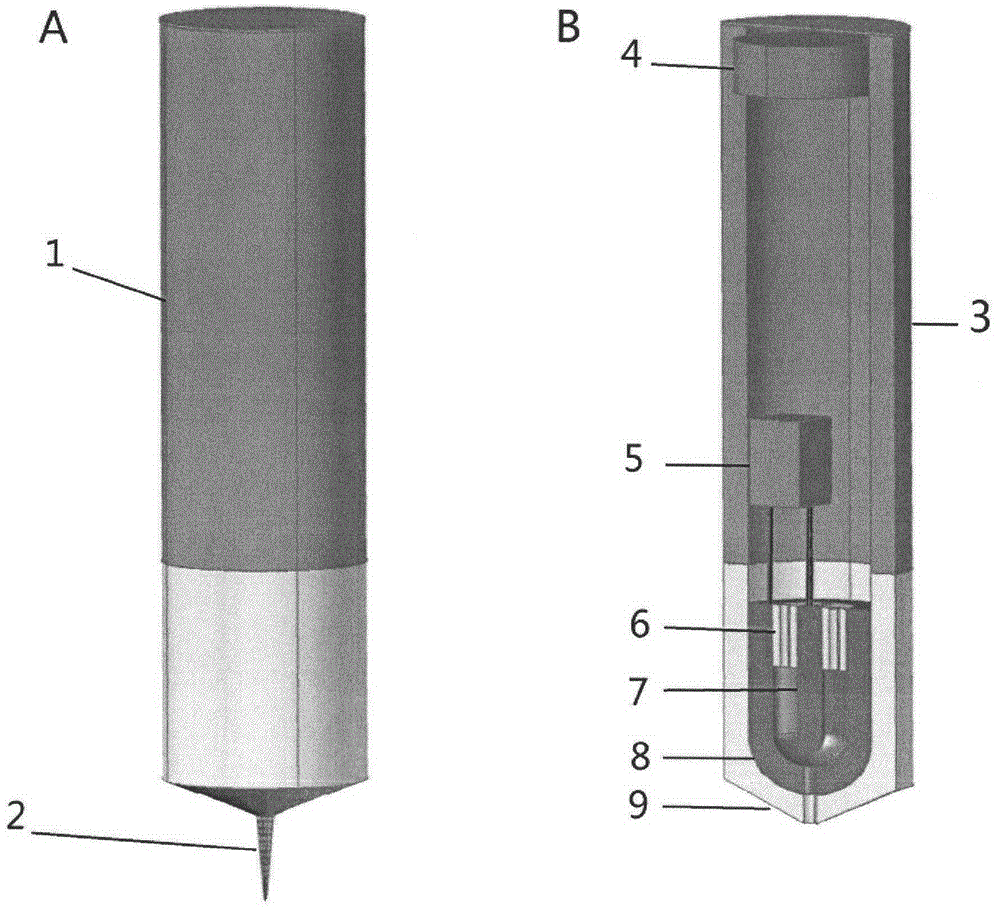

[0015] as attached figure 1 As shown, the present invention includes an insulating shell 3, a micro fan 4, a high-voltage power supply 5, an inner electrode 7, a ceramic ring 6 with diversion holes, an outer electrode 8 and a ceramic nozzle 9. The insulating shell 3 is connected to the ceramic nozzle 9 to form a cavity. The insulating shell 3 is made of epoxy resin. The micro-fan 4 is placed on the top central axis of the insulating shell 3. , The ceramic ring 6 and the outer electrode 8 are placed on the central axis of the ceramic nozzle 9, the inner electrode 7 and the outer electrode 8 are respectively connected to the high voltage power supply 5, the top of the inner electrode 7 is a hemispherical cylinder, the top of the outer electrode 8 is a concave surface, ceramic The ring 6 is placed between the two electrodes to prevent discharge short circuit and fix the supporting electrodes. The inner electrode 7 and the outer electrode 8 are made of copper. Start the high-volt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com