Efficient filtering device for purifying and disinfecting air

A high-efficiency filtration and air purification technology, applied in the field of high-efficiency filtration devices and high-efficiency filtration devices for air purification and disinfection, can solve the problems of incomplete purification effect, high use cost, secondary pollution, etc., to ensure electrical conductivity and enhance adsorption function. , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

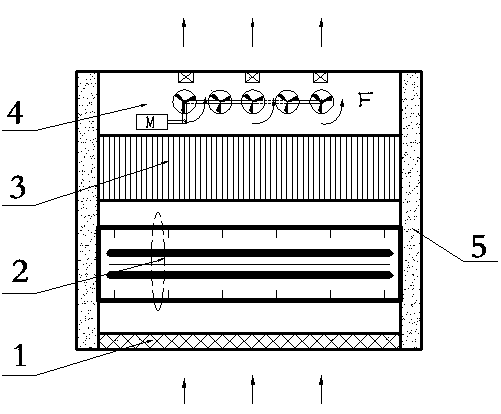

[0035] This example is attached figure 1 As shown, the electrostatic primary effect filter screen 1 is set at the outermost opening of the sealed air duct 5, the plasma polymerized filter layer 2 is set at the middle position, and the functional ceramic composite filter screen 3 is set at the inner mouth of the sealed air duct. A gap not exceeding the thickness of the filter screen is left between the filter screen filter layers, and the air exchange device 4 adopts a negative pressure suction fan, which is arranged on the outside of the functional ceramic composite filter screen 3 .

[0036] The electrostatic primary effect filter 1 in this embodiment is composed of a stainless steel frame and a carbon fiber screen. The single mesh area of the carbon fiber screen is 0.35 square millimeters, and the hole material hollowing ratio of the entire screen is about 80%. The stainless steel frame of the electrostatic primary effect filter is matched with the guide groove inside the...

Embodiment 2

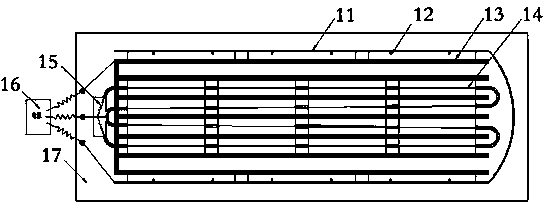

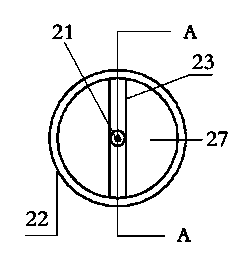

[0042] The structure of this embodiment is basically the same as that of Embodiment 1, the only difference is that the plasma polymerization filter layer in this embodiment adopts a "barrel-needle plasma generation assembly", and the barrel-needle plasma generation assembly structure as attached image 3 As shown, the assembly is composed of twelve barrel-needle plasma generating units, and the structure of a single barrel-needle plasma generating unit is shown in the attached Figure 4 And attached Figure 5 shown. The needle-shaped negative electrode 21 of the component is electrically connected to the negative electrode of the combined power supply, the cylindrical positive electrode 22 of the component is electrically connected to the positive electrode of the combined power supply, and the voltage difference between the positive electrode and the negative electrode is adjusted to 16Kv .

[0043] The air filtering mechanism and process of this embodiment are the same as...

Embodiment 3

[0045] This embodiment provides the manufacturing process of multifunctional composite conductive ceramic honeycomb screen,

[0046] (1) Evenly mix the metal oxide aluminum oxide, raw diatomaceous earth and nano-scale bamboo activated carbon by weight percentage: 10% aluminum oxide, 40% raw diatomite, and 50% nano-scale woody activated carbon %;

[0047] (2) Slurry the above-mentioned aluminum oxide, raw diatomite and nano-scale bamboo activated carbon with pure water, put them into a mold, and mold them;

[0048] (3) Sinter tires, the sintering temperature is 850°C;

[0049] (4) Coating 5 layers of nano-scale titanium dioxide photocatalyst materials in the mesh holes of the ceramic honeycomb mesh plate made of sintering;

[0050] (5) Carry out secondary sintering, and the stencil tire after coating the nano-scale titanium dioxide photocatalyst material is sintered for the second time, and the sintering temperature is 550°C.

[0051] In this embodiment, Al2O3 can enhance th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com