Method for improving visible light catalytic performance of Ag3PO4

A catalytic performance and visible light technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of complex visible light catalytic performance and process, and achieve improved visible light catalytic effect, low cost and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

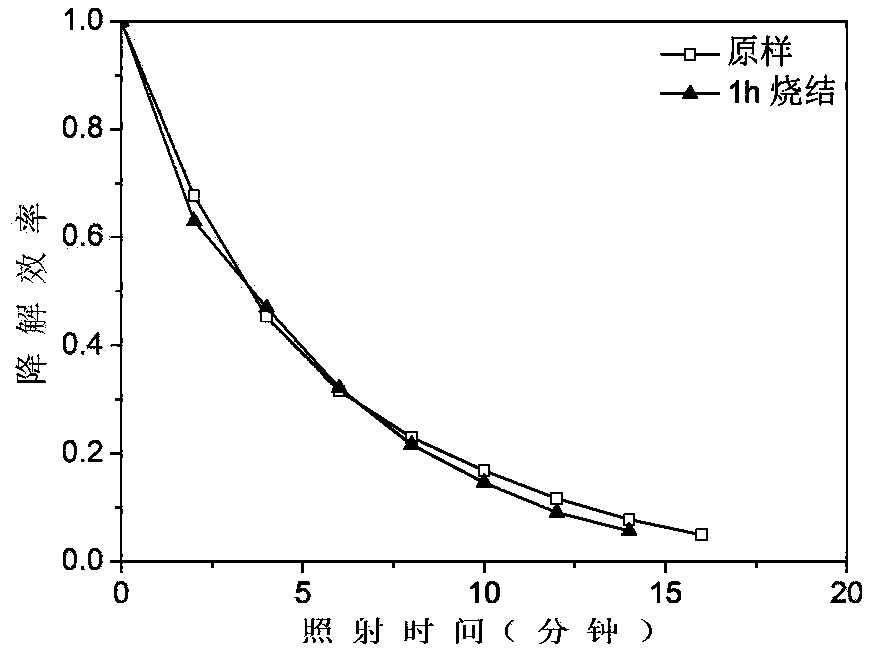

[0024] Spherical Ag 3 PO 4 Put it in a muffle furnace, raise the temperature to 380°C in an air atmosphere, keep it warm for 1h, and then cool it down to room temperature naturally to obtain the sintered Ag 3 PO 4 .

[0025] Take 0.1g of Ag before sintering 3 PO 4 Add the sample to 100mL rhodamine B with a concentration of 10mg / L, and stir for 30min in the dark, then take a sample every two minutes under the irradiation of visible light, centrifuge to take the supernatant, measure the absorbance, record the data, and draw it into a graph . The same method for the sintered Ag 3 PO 4 The samples were subjected to visible light catalysis experiments. See the experimental results figure 1 , the visible light catalytic degradation effect of the sintered sample is better than that before sintering, which is increased by nearly 10%.

Embodiment 2

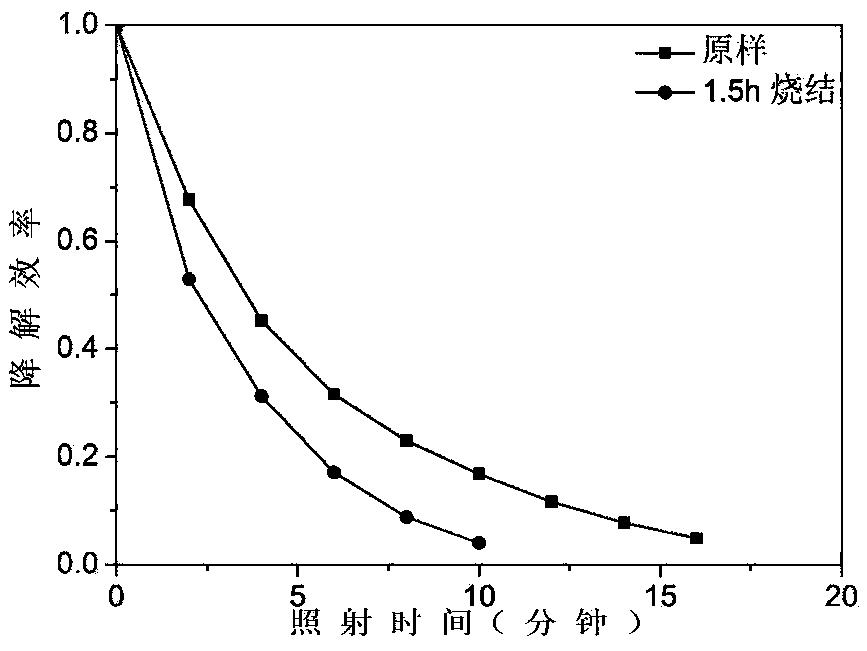

[0027] Spherical Ag 3 PO 4 Put it in a muffle furnace, raise the temperature to 400°C in an air atmosphere, keep it warm for 1.5h, and then cool it down to room temperature naturally to obtain the sintered Ag 3 PO 4 .

[0028] Take 0.1g of Ag before sintering 3 PO 4 Add the sample to 100mL rhodamine B with a concentration of 10mg / L, and stir for 30min in the dark, then take a sample every two minutes under the irradiation of visible light, centrifuge to take the supernatant, measure the absorbance, record the data, and draw it into a graph . The same method for the sintered Ag 3 PO 4 The samples were subjected to visible light catalysis experiments. See the experimental results figure 2 , the visible light catalytic degradation effect of the sintered sample is better than that before sintering, which is nearly 37.5% higher. Example 3

Embodiment 3

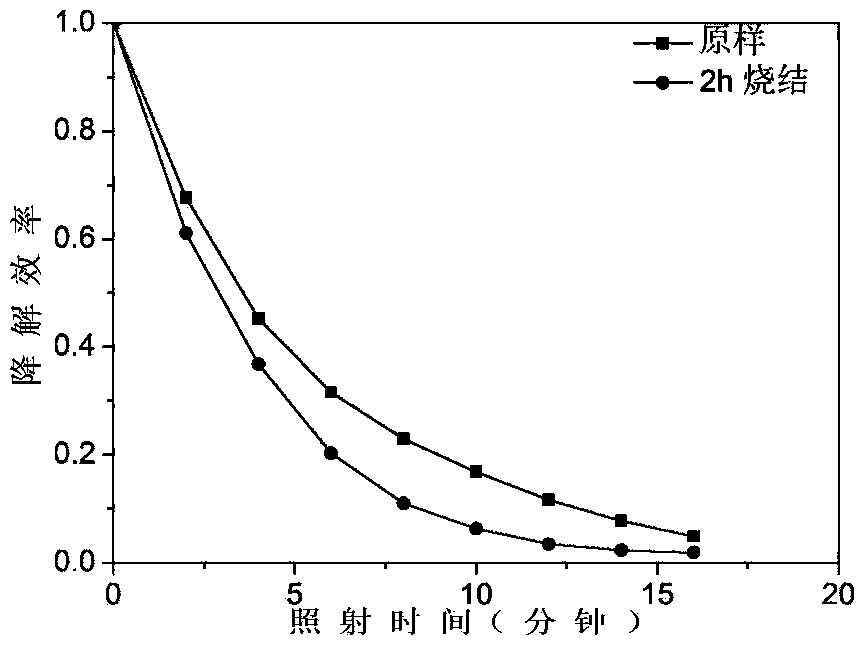

[0029] Spherical Ag 3 PO 4 Put it in a muffle furnace, raise the temperature to 420°C in an air atmosphere, keep it warm for sintering for 2 hours, and then cool it down to room temperature naturally to obtain the sintered Ag 3 PO 4 .

[0030] Take 0.1g of Ag before sintering 3 PO 4 Add the sample to 100ml Rhodamine B with a concentration of 10mg / L, and stir for 30min in the dark, then take a sample every two minutes under visible light irradiation, centrifuge to take the supernatant, measure the absorbance, record the data, and draw it into a graph . The same method for the sintered Ag 3 PO4 The samples were subjected to visible light catalysis experiments. See the experimental results image 3 , the visible light catalytic degradation effect of the sintered sample is better than that before sintering, which is increased by nearly 21%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com