A kind of modification method of guar polysaccharide gum

A guar polysaccharide and modification technology, which is applied in the field of modification of guar polysaccharide gum, can solve the problems of turbidity of polysaccharide gum aqueous solution, well plugging by fracturing fluid, affecting application, etc., and achieves reduction of water-insoluble matter content and good compatibility. , the effect of less water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 protease treatment guar polysaccharide gum

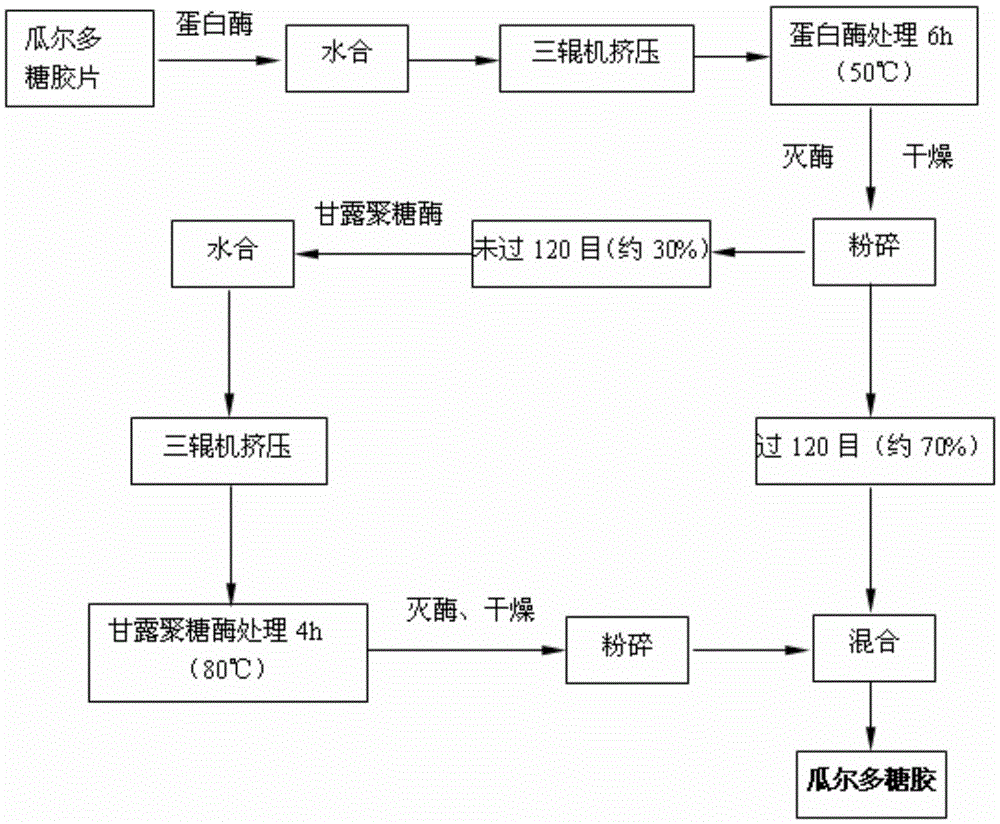

[0023] according to figure 1 The process flow diagram of the modification method of guar polysaccharide gum shown, the guar polysaccharide gum is modified.

[0024] 1. Add the guar polysaccharide film with a water insoluble content of 24.8% to the protease aqueous solution for hydration treatment for 30 minutes, the solid-liquid ratio is 1:1.1, and the protease dosage is 30U / g.

[0025] 2. After hydration, extrude the fully swollen film into a snowflake shape on a three-roll machine, and transfer the extruded guar polysaccharide gum into a homogeneous reactor for 6 hours at a temperature of 50°C.

[0026] 3. After the reaction is finished, carry out inactivation treatment in a sterilizing pot, the inactivation temperature is 121° C., and the time is 20 minutes.

[0027] 4. After the inactivation is completed, dry the protease-treated guar polysaccharide gum in an oven at 60° C. for 3 hours.

[0028] 5. The wat...

Embodiment 2

[0029] Embodiment 2 protease treatment guar polysaccharide gum

[0030] The difference between this embodiment and embodiment 1 is only: the dosage of protease is 50U / g;

[0031] After protease treatment, the water-insoluble content of the guar polysaccharide gum was detected, and the result was 17.7%.

Embodiment 3

[0032] Embodiment 3 protease treatment guar polysaccharide gum

[0033] The difference between this embodiment and embodiment 1 is only: the amount of protease is 100U / g;

[0034] After protease treatment, the water-insoluble content of guar polysaccharide gum was detected, and the result was 16.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com