A kind of micro-aqueous solid-phase modification method of saponins polysaccharide gum

A technology for polysaccharide gum and acacia, which is applied in the field of micro-water solid phase modification of acacia polysaccharide gum, can solve the problems of few research reports on the modification of acacia polysaccharide gum, achieves a simple and efficient modification process, expands application fields, penetrates easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

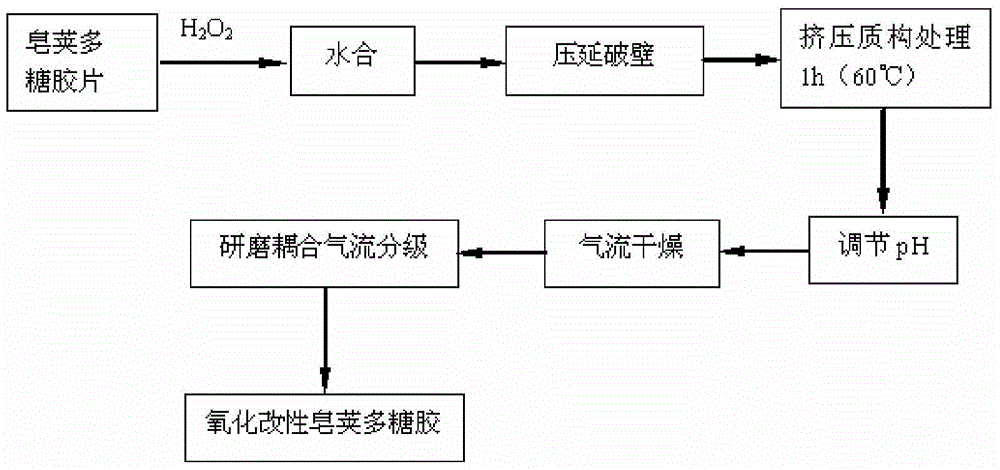

[0032] according to figure 1 As shown in the process flow chart, the saponins polysaccharide film is hydrated with an aqueous hydrogen peroxide solution with a pH of 11 (the concentration of hydrogen peroxide in water is 3%), and the mass ratio of solid to liquid is 1:1. After hydration for 15 minutes, the fully swollen film was calendered on a three-roll machine to form broken flakes into snowflakes, and then subjected to extrusion texture treatment in a screw extrusion reactor for 1 hour at a temperature of 60 °C. After the reaction, spray and add 10% hydrochloric acid solution to adjust the pH value to neutral, then carry out air-drying, grinding and pulverizing coupled with air-flow classification, and obtain the modified product of acacia polysaccharide gum passing through a 120-mesh sieve. The measured molecular weight of the modified product is 1.92 million, the carboxyl substitution degree is 0.07, and the water-insoluble content is 8.7%.

Embodiment 2

[0034] according to figure 1 As shown in the process flow chart, the saponins polysaccharide film is hydrated with an aqueous hydrogen peroxide solution with a pH of 11 (the concentration of hydrogen peroxide in water is 10%), and the mass ratio of solid to liquid is 1:1. After hydration for 15 minutes, the fully swollen film was calendered on a three-roll machine to form broken flakes into snowflakes, and then subjected to extrusion texture treatment in a screw extrusion reactor for 1 hour at a temperature of 60 °C. After the reaction, spray and add 10% hydrochloric acid solution to adjust the pH value to neutral, then carry out air-drying, grinding and pulverizing coupled with air-flow classification, and obtain the modified product of acacia polysaccharide gum passing through a 120-mesh sieve. The measured molecular weight of the modified product is 89,000, the carboxyl substitution degree is 0.45, and the water-insoluble content is 8.5%.

Embodiment 3

[0037] according to figure 1 As shown in the process flow chart, the saponins polysaccharide film is hydrated with an aqueous hydrogen peroxide solution with a pH of 11 (the concentration of hydrogen peroxide in water is 15%), and the mass ratio of solid to liquid is 1:1. After hydration for 15 minutes, the fully swollen film was calendered on a three-roll machine to form broken flakes into snowflakes, and then subjected to extrusion texture treatment in a screw extrusion reactor for 1 hour at a temperature of 60 °C. After the reaction, spray and add 10% hydrochloric acid solution to adjust the pH value to neutral, then carry out air-drying, grinding and pulverizing coupled with air-flow classification, and obtain the modified product of acacia polysaccharide gum passing through a 120-mesh sieve. The measured molecular weight of the modified product is 70,000, the carboxyl substitution degree is 0.54, and the water-insoluble content is 8.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com