Mechanical-activation solid-phase preparation method of lignocellulose ester group oxidation catalyst

A lignocellulose, oxidation catalyst technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the high cost of production and use of heterogeneous catalysts, recovery and regeneration process Complex problems, to achieve the effect of low cost, low production cost, and equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

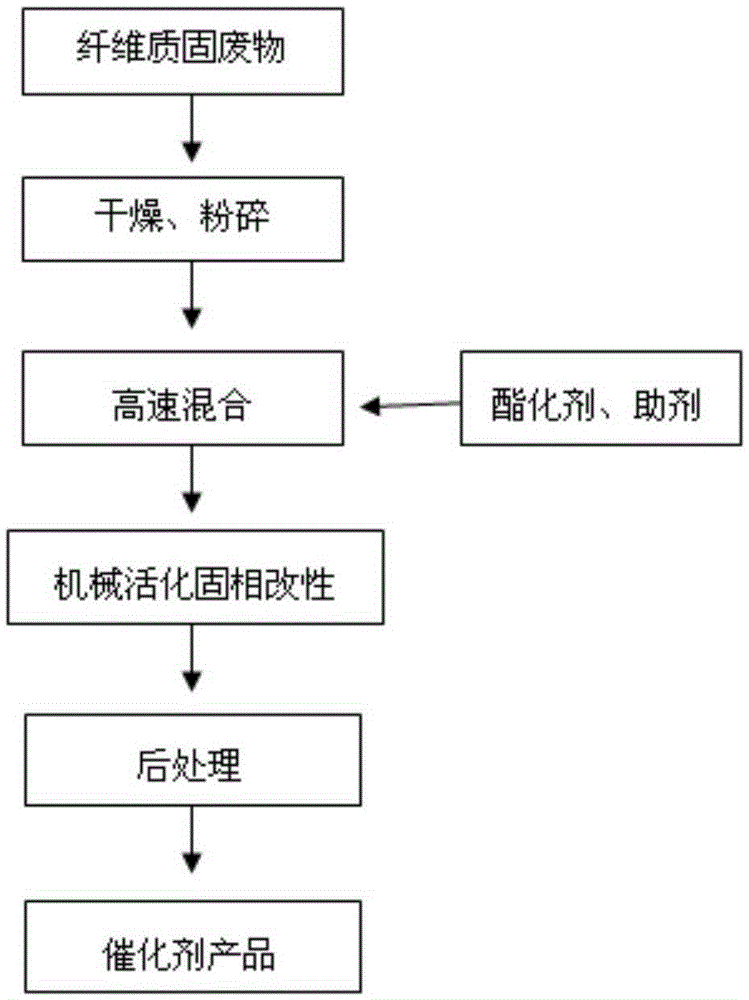

[0037] A kind of mechanical activation solid-phase preparation method of lignocellulose ester-based oxidation catalyst, the preparation method comprises the following steps:

[0038] (1) raw material pretreatment: drying the bagasse fibrous solid waste to a moisture content of less than 15%, pulverizing to obtain a fibrous solid waste powder passing through a 20-mesh sieve;

[0039] (2) High-speed mixing: the fibrous solid waste powder, esterification agent succinic acid and auxiliary agent AlCl 3 Add it to the mixer at a ratio of 100:5:1 and mix evenly to obtain a mixture;

[0040] (3) Mechanically activated solid-phase reaction: Add the above-mentioned mixture into the mechanically activated solid-phase reactor according to the ratio of 100g:200ml of the volume of the milling medium, and perform ball milling reaction at a speed of 200rpm and a constant temperature water bath temperature of 30°C to achieve 0.5h activation After a period of time, stop stirring, take out the e...

Embodiment 2

[0043] A kind of mechanical activation solid-phase preparation method of lignocellulose ester-based oxidation catalyst, the preparation method comprises the following steps:

[0044] (1) Raw material pretreatment: drying cassava distiller's grains fibrous solid waste to a moisture content of less than 10%, pulverizing to obtain fibrous solid waste powder passing through a 25-mesh sieve;

[0045] (2) High-speed mixing: mix the fibrous solid waste powder, esterification agent maleic acid and auxiliary agent KNO 3 Add it to the mixer in a ratio of 100:10:2 and mix evenly to obtain a mixture;

[0046] (3) Mechanically activated solid-phase reaction: add the volume of the above-mentioned mixture into the mechanically activated solid-phase reactor according to the ratio of 100g:250ml, and perform ball milling reaction at a speed of 250rpm and a constant temperature water bath temperature of 35°C to achieve 0.6h activation After a period of time, stop stirring, take out the esterifi...

Embodiment 3

[0049] A kind of mechanical activation solid-phase preparation method of lignocellulose ester-based oxidation catalyst, the preparation method comprises the following steps:

[0050] (1) raw material pretreatment: drying cassava stalk fibrous solid waste to a water content less than 5%, pulverizing to obtain fibrous solid waste powder passing through a 30-mesh sieve;

[0051] (2) High-speed mixing: the fibrous solid waste powder, esterification agent oxalic acid and additive Na 2 CO 3 Add it to the mixer in a ratio of 100:15:3 and mix evenly to obtain a mixture;

[0052] (3) Mechanically activated solid-phase reaction: add the above-mentioned mixture into the mechanically activated solid-phase reactor according to the ratio of 100g:300ml, and perform ball milling reaction at a speed of 300rpm and a temperature of 40°C constant temperature water bath to achieve 0.7h activation After a period of time, stop stirring, take out the esterification product and the balls, and separa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com