Preparation method of sulfydryl lignin for regenerating waste rubber

A waste rubber and lignin technology, which is applied in the field of waste rubber regeneration, can solve the problems of low cost of use, achieve low cost of use, solve environmental pollution problems, and achieve high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

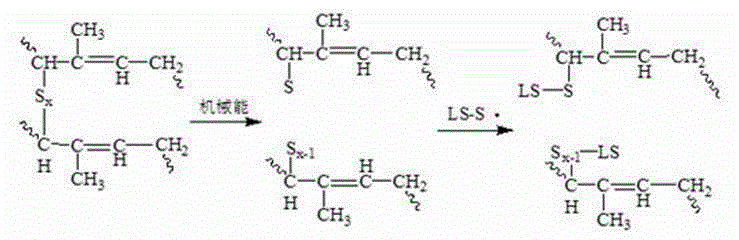

Method used

Image

Examples

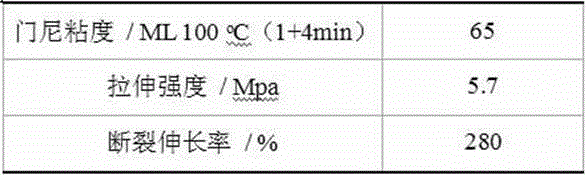

Embodiment 1

[0019] Add 6.5 g of mercaptoacetic acid, 3.8 g of acetic anhydride, and 1.0 g of concentrated sulfuric acid into a brown ground-mouth jar, mix well, add 5 g of kraft lignin powder, mix well, cover and seal, and place in an oven for 40 o C was kept at a constant temperature for 6 h. The mixture was taken out, vacuum filtered, and washed repeatedly with absolute ethanol to neutrality, 40 o C under vacuum drying to obtain this mercapto lignin regeneration agent for subsequent use. The thiol content was determined to be 1.52% by back titration argentometric method.

[0020] Grind waste butyl rubber tires into a fine powder of about 20 meshes, mix with mercapto lignin regeneration agent at a mass ratio of 100:12, mix in a mixer for more than 5 minutes, and press the mixer for 3 times After the film is released, the finished reclaimed rubber product is obtained. The finished reclaimed rubber can be directly put on the vulcanizer at 145 o C vulcanization to obtain rubber product...

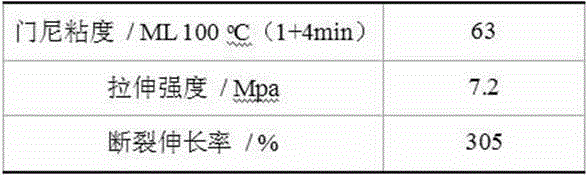

Embodiment 2

[0023] Add 7 g of thioglycolic acid, 4.0 g of acetic anhydride, and 1.0 g of concentrated sulfuric acid into a brown ground-mouth jar, mix well, add 5 g of kraft lignin powder, mix well, cover and seal, and place in an oven for 40 o C was kept at a constant temperature for 6 h. The mixture was taken out, vacuum filtered, and washed repeatedly with absolute ethanol to neutrality, 40 o C under vacuum drying to obtain this mercapto lignin regeneration agent for subsequent use. The sulfhydryl content was determined to be 1.43% by back titration argentometric method.

[0024] Grind waste ethylene-propylene rubber tires into a fine powder of about 20 meshes with a grinder, mix with mercapto lignin regenerant at a mass ratio of 100:15, mix in a mixer for more than 5 minutes, and press into tablets with a mill for 3 After several times, the film is produced to obtain the finished reclaimed rubber. The finished reclaimed rubber can be directly on the vulcanizing machine for 100 o ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com