An ultrasonic atomized polishing solution suitable for tft-lcd glass substrates

A technology of ultrasonic atomization and polishing liquid, applied in polishing compositions containing abrasives, etc., to achieve the effects of easy cleaning, high material removal rate, and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 90g of deionized water to 12g of cerium oxide with a particle size of 50nm, and keep stirring until the solution does not precipitate; then add 50g of silicon oxide to the mixed solution with a mass fraction of 30% silica sol (the particle size of the silicon oxide is 15~20nm), stirring while adding; adding hydroxyethylethylenediamine and deionized water, stirring constantly and adjusting the pH of the solution to 11; 300g, and then ultrasonically dispersed (frequency 40kHz, power 70W) for 30 minutes.

[0026] Effects of use: Pour the polishing liquid into an ultrasonic atomizer, conduct an atomization polishing experiment, polish for 5 minutes, then perform 1 minute of water polishing, rinse with deionized water after polishing, and dry. It is measured that the removal rate of glass reaches 202nm / min, and the surface roughness reaches 1.35nm. Under the same polishing parameters, the polishing liquid was used for traditional polishing experiments, and the measured ...

Embodiment 2

[0028] Add 90g of deionized water to 18g of cerium oxide with a particle size of 50nm, and keep stirring until the solution does not precipitate; then add 120g of silicon oxide to the mixed solution with a mass fraction of 30% silica sol (the particle size of the silicon oxide is 15~20nm), stirring while adding; adding ethylenediamine and deionized water, stirring constantly and adjusting the pH of the solution to 11.5; then adding 4.5g of polyvinylpyrrolidone, stirring continuously to make it fully dissolved, so that the solution reached 300g, and then Ultrasonic dispersion (frequency 40kHz, power 70W) for 20 minutes.

[0029] Effects of use: Pour the polishing liquid into an ultrasonic atomizer, conduct an atomization polishing experiment, polish for 5 minutes, then perform 1 minute of water polishing, rinse with deionized water after polishing, and dry. It is measured that the removal rate of glass reaches 180nm / min, and the surface roughness reaches 1.52nm.

Embodiment 3

[0031] Add 60g of deionized water to 8g of cerium oxide with a particle diameter of 50nm, and keep stirring until the solution does not precipitate; then add 100g of silicon oxide to the mixed solution with a mass fraction of 30% silica sol (the particle diameter of silicon oxide is 15~20nm), stir while adding; add hydroxyethylethylenediamine and deionized water, keep stirring and adjust the pH of the solution to 10.5; then add 2g of polyvinylpyrrolidone, keep stirring to fully dissolve it, and make the solution reach 200g , and then ultrasonically dispersed (frequency 40kHz, power 70W) for 25 minutes.

[0032] Effects of use: Pour the polishing liquid into an ultrasonic atomizer, conduct an atomization polishing experiment, polish for 5 minutes, then perform 1 minute of water polishing, rinse with deionized water after polishing, and dry. It is measured that the removal rate of glass reaches 189nm / min, and the surface roughness reaches 1.42nm.

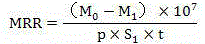

[0033] The formula for calcul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com