Pile-anchor-frame composite double-layer roadbed structure

A frame and double-layer technology, applied in the direction of infrastructure engineering, roads, roads, etc., can solve problems such as difficult to ensure environmental and economic benefits, and achieve the effects of reducing the damage of natural mountains, improving comprehensive performance, and reducing engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

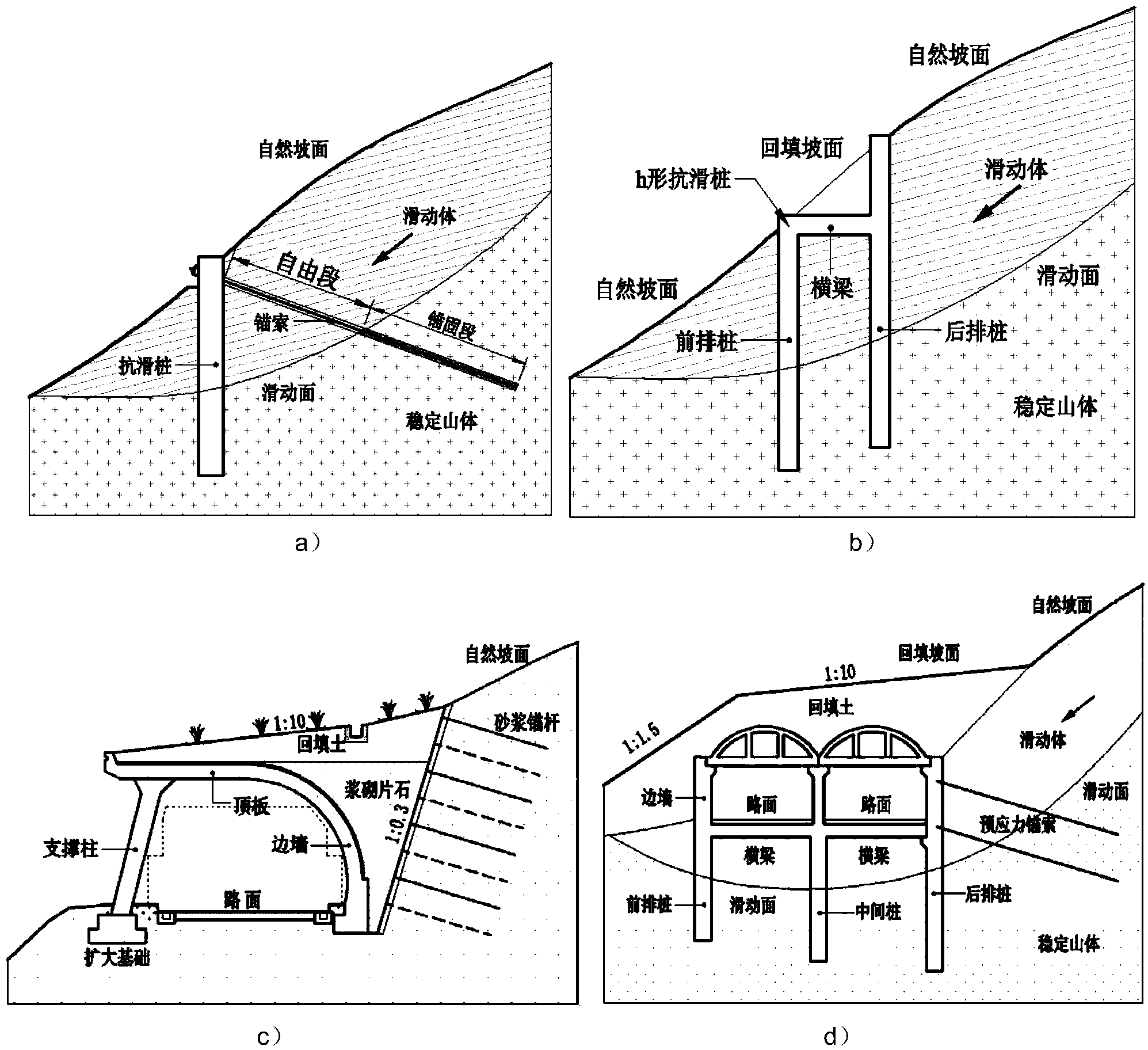

[0039] For the specific "pile-anchor-frame" composite double-layer subgrade structure, see Figure 3-Figure 6 .

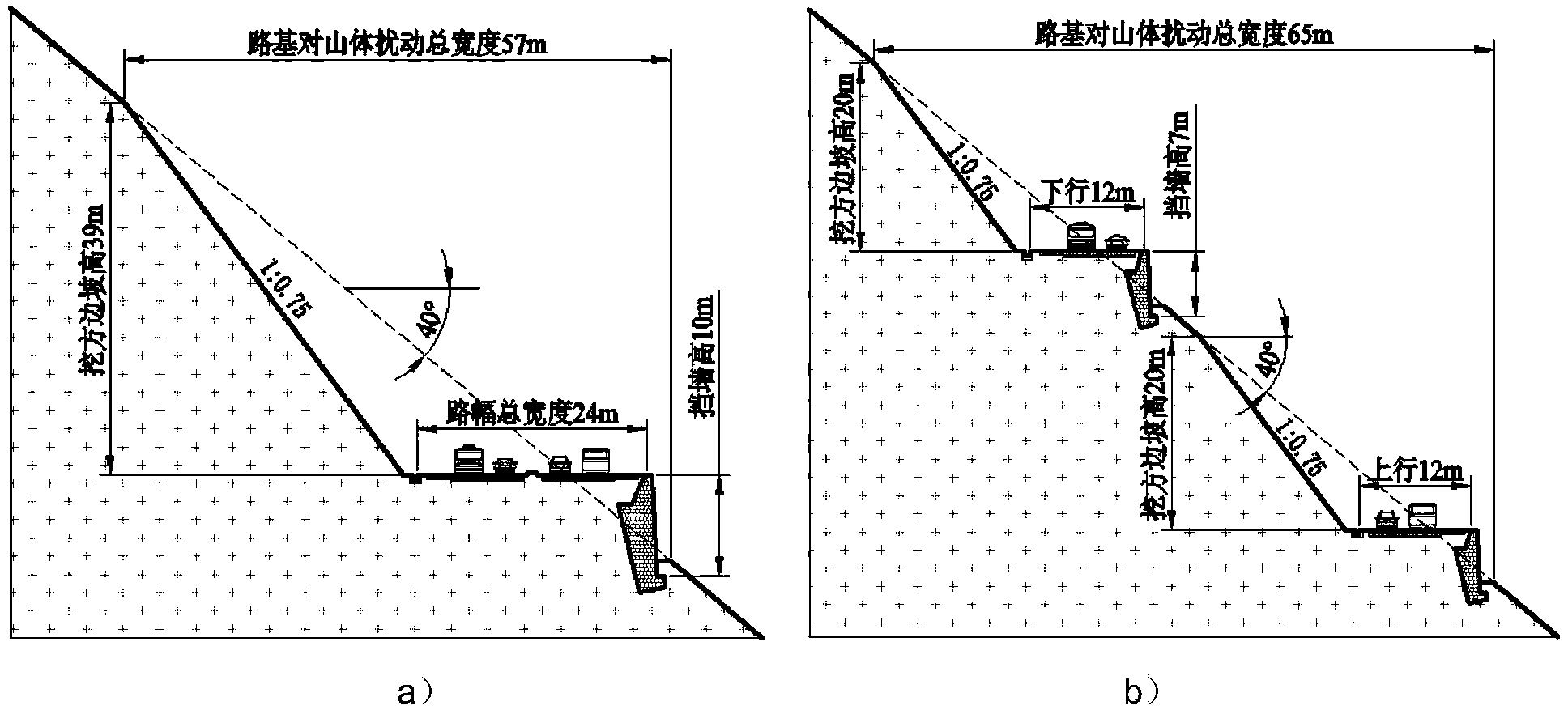

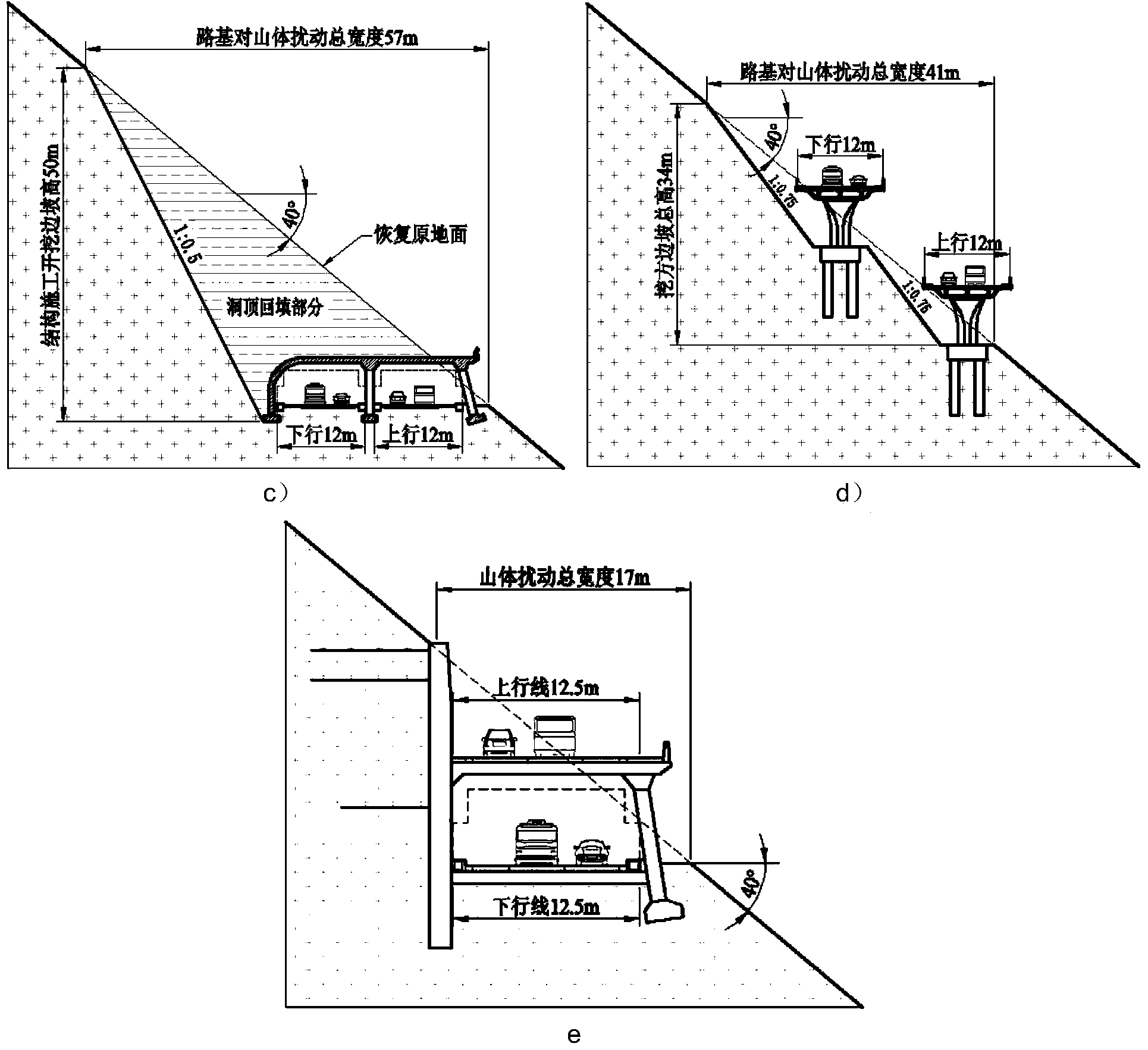

[0040] When the present invention is used on a four-lane expressway or a first-class highway with a ground transverse slope of 30° to 45°, two lanes are arranged on the upper and lower road slabs, and the clear width of the road slab=2×3.75m (lane width)+2.5 m (emergency parking bandwidth) + 0.5m (left lateral width) + 0.5m (right lateral width) = 11m, cover plate side ditch top width = 0.75m (sidewalk) + 0.5m (lateral width) = 1.25 m, the clearance height of the lower road slab is 5m, such as Figure 7 As shown; when the ground slope is 25°-40° six-lane expressway or first-class highway, the upper and lower road slabs are respectively arranged with 3 lanes, and the clear width of the road slab=3×3.75m (lane width)+3m( Emergency parking bandwidth) + 0.75m (left lateral width) + 0.75m (right lateral width) = 15.75m, cover side ditch top width = 1m (sidewalk) + 0.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com