An integrated thermal insulation decorative plate and its production process

A decorative panel and production process technology, applied in thermal insulation, building components, covering/lining, etc., can solve the problems of production technology staying in the manual or semi-mechanized operation stage, ignoring product comprehensive performance and safety performance research, and extensive production technology. Achieve the effect of various designs and colors, grand appearance and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

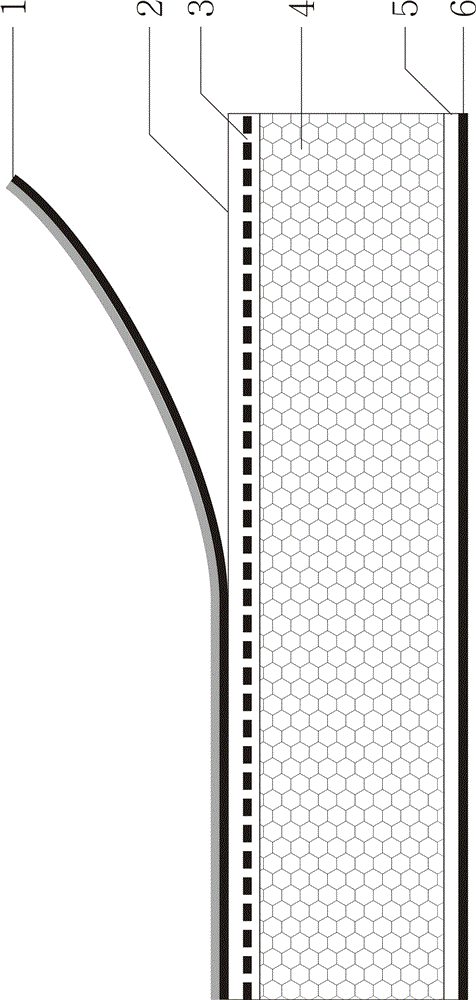

[0022] Example 1, such as figure 1 and figure 2 The integrated thermal insulation and decorative board shown includes the thermal insulation core material 4 and the upper glued layer 2 coated on the upper surface of the thermal insulation core material 4. The upper glued layer 2 is provided with a glass fiber mesh cloth 3, and the surface of the upper glued layer 2 is Laying and pasting the glass fiber-based decorative surface layer 1 .

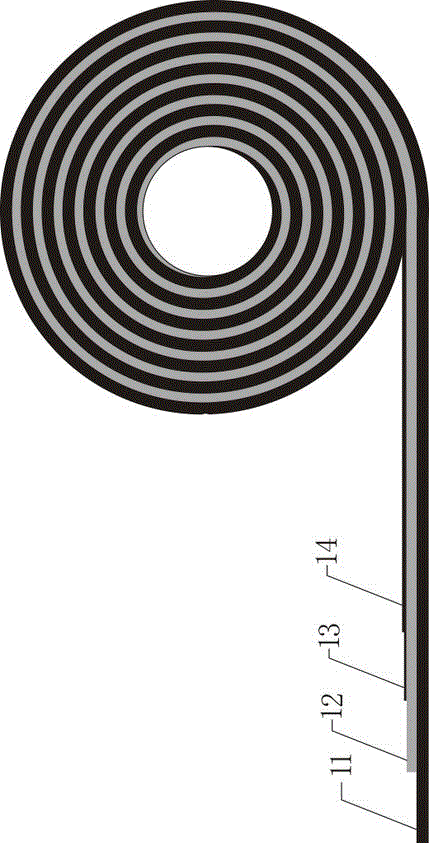

[0023] The thickness of the glass fiber-based decorative surface layer 1 is 0.3-1mm, which includes a glass fiber non-woven fabric base layer 11 and a finish layer 13 made of exterior wall paint, and the glass fiber non-woven fabric base layer 11 is coated with 0.5-1mm thick A flexible base coat 12, a finish layer 13 is coated on the flexible base coat 12, and a hydrophobic and waterproof surface oil layer 14 is sprayed on the finish layer 13.

[0024] A glass fiber cement-based cloth 6 is pasted on the lower surface of the thermal insulat...

Embodiment 2

[0033] Embodiment 2 is different from Embodiment 1 in that: the glass fiber-based decorative surface layer 1 includes a glass fiber non-woven fabric base layer and a facing layer with a granite or marble texture pattern, and the facing layer is printed on the glass fiber non-woven fabric. On the base layer of the cloth, a hydrophobic and waterproof surface oil layer is sprayed on the decorative layer of the granite or marble texture pattern.

[0034] The difference between the production process of Example 2 and Example 1 lies in step a, that is, the veneer layer with granite or marble texture patterns is transferred to the glass fiber non-woven The surface of the cloth; the release paper of the thermal transfer film is peeled off by the peeling roller; then, the nozzle sprays the transparent protective surface oil on the finish layer to form a hydrophobic and waterproof surface oil layer, which is dried by the hot air drying system and then collected The winding machine is us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com