Double-side strengthened heat transfer smoke tube of vertical gas-fired hot water boiler

A gas-fired hot water and enhanced heat transfer technology, which is applied in the field of smoke pipes, can solve the problems of small convective heat transfer coefficient between flue gas and pipe wall, low thermal efficiency of vertical gas-fired hot water boilers, and insufficient heat transfer area of smoke pipes. , to achieve the effect of improving boiler thermal efficiency, strengthening convective heat transfer, and reducing circulation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

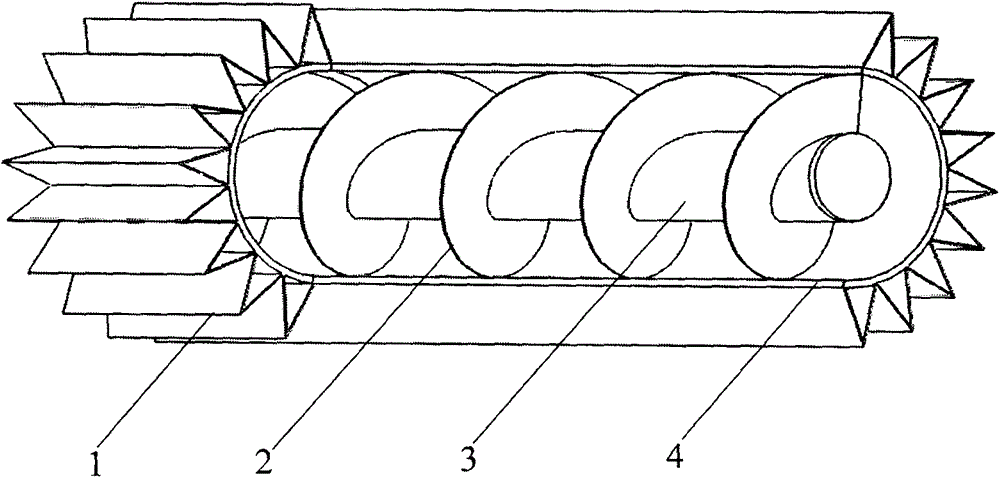

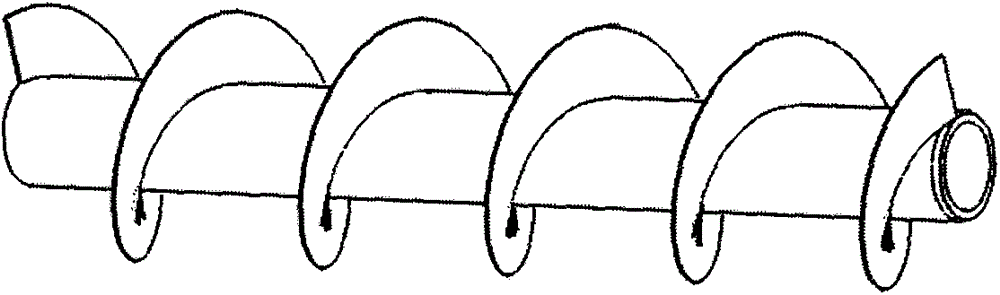

[0013] Such as figure 1 As shown, a double-sided enhanced heat transfer smoke tube of a vertical gas-fired hot water boiler includes longitudinal corrugated fins 1, spiral fins 2, blind tubes 3 and smoke tubes 4, and the longitudinal corrugated fins 1 are set outside the smoke tube 4 On the wall, the helical piece 2 is wound on the outer wall of the blind pipe 3, and then inserted into the smoke pipe 4 as a whole, and the dead pipe 3 and the smoke pipe 4 are equal in length.

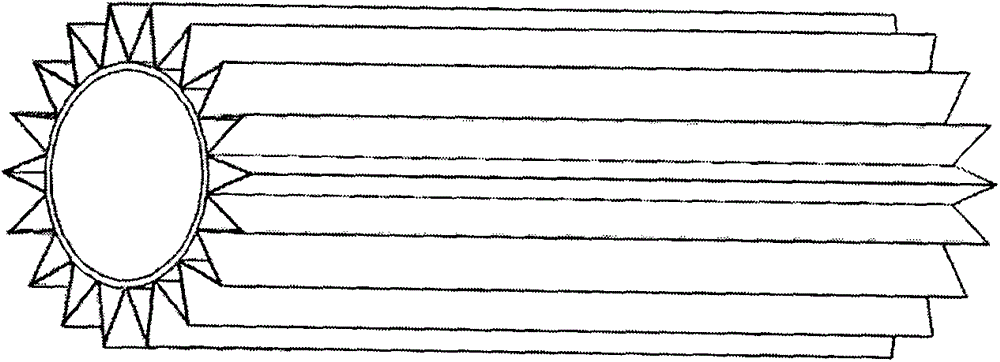

[0014] Longitudinal corrugated fins 1 are made of thin steel plates folded repeatedly according to the width of half the distance between the smoke pipes and then crimped and welded. The overall longitudinal corrugated fins 1 are tightly fitted on the outer wall of the smoke pipe 4 by high-frequency welding, which can significantly increase the size of the outside of the smoke pipe 4. The heat exchange area, the smoke pipe 4 and the longitudinal corrugated fins 1 are both arranged vertically, which will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com