Iron doped cobaltosic oxide nano-film as well as preparation method and application thereof

A nano- and iron-doped technology of cobalt trioxide, which is applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of unsatisfactory catalytic efficiency, achieve outstanding electrical conductivity and catalytic performance, simple and environmentally friendly preparation methods, and economical and effective preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

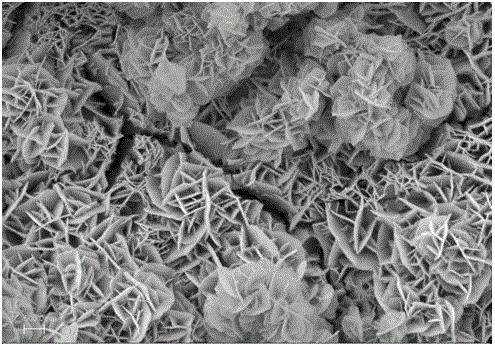

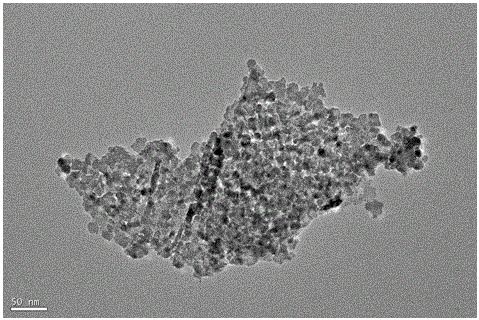

[0044] The preparation method of the iron-doped tricobalt tetroxide nanofilm:

[0045] 1) The Co(NO 3 ) 2 ·6H 2 O, FeCl 2 4H 2 O and KCl are configured into a dilute solution of 100ml, and the solution is ultrasonicated for 10min after preparation,

[0046] By changing Co(NO 3 ) 2 ·6H 2 O and FeCl 2 4H 2 The molar ratio of O, prepare 5 kinds of solutions respectively, the Co(NO in 5 kinds of solutions 3 ) 2 ·6H 2 The concentration of O is 0.05M, the concentration of KCl is 0.1M, the FeCl in the five solutions 2 4H 2 The concentration of O is respectively 0.005M, 0.00625M, 0.01M, 0.025M, and 0.05M.

[0047] 2) Take 5 pieces of FTO conductive glass with a size of 1.5cm×1.0cm, wash them sequentially with washing powder water, double distilled water, ethanol with a volume fraction of 95%-99.5%, and ultrapure water, and then blow them under a nitrogen environment. Dry, get the FTO conductive glass after processing clean;

Embodiment 2

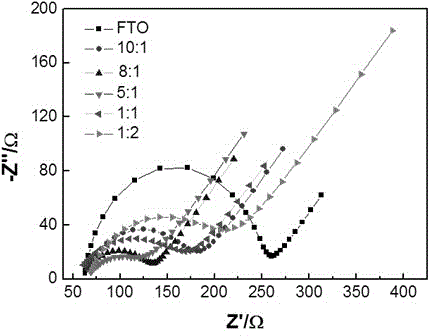

[0056] Iron-doped Co3O3 nanofilm as working electrode for electrocatalytic reduction of oxygen

[0057] 1) Nitrogen was passed through 10ml of the prepared 0.1M KOH solution for 20 minutes to remove the oxygen contained in the solution, and the five kinds of iron-doped cobalt tetroxide nano-films prepared in Example 1 were used as working electrodes, and the three-electrode system was used to remove oxygen, that is, nitrogen Carry out cyclic voltammetry scan in saturated KOH solution, the scan rate is 0.1V / s;

[0058] 2) Pass oxygen through 10ml of the prepared 0.1M KOH solution for 20 minutes to saturate the oxygen in the solution, and use the five iron-doped cobalt tetroxide nanofilms prepared in Example 1 as working electrodes, and use the three-electrode system in oxygen-saturated KOH Carry out cyclic voltammetry scanning in the solution, the scanning speed is 0.1V / s;

[0059] pass Figure 6 It can be seen that under the condition of nitrogen saturation, the iron-doped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com