Linear type electro-hydraulic

An electro-hydraulic pump, linear technology, applied in the direction of pump, pump control, piston pump, etc., can solve the problems of aggravating energy friction loss, high production cost and operating cost, and wide variation range, and achieves improved efficiency and energy utilization. , the effect of high energy utilization efficiency and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

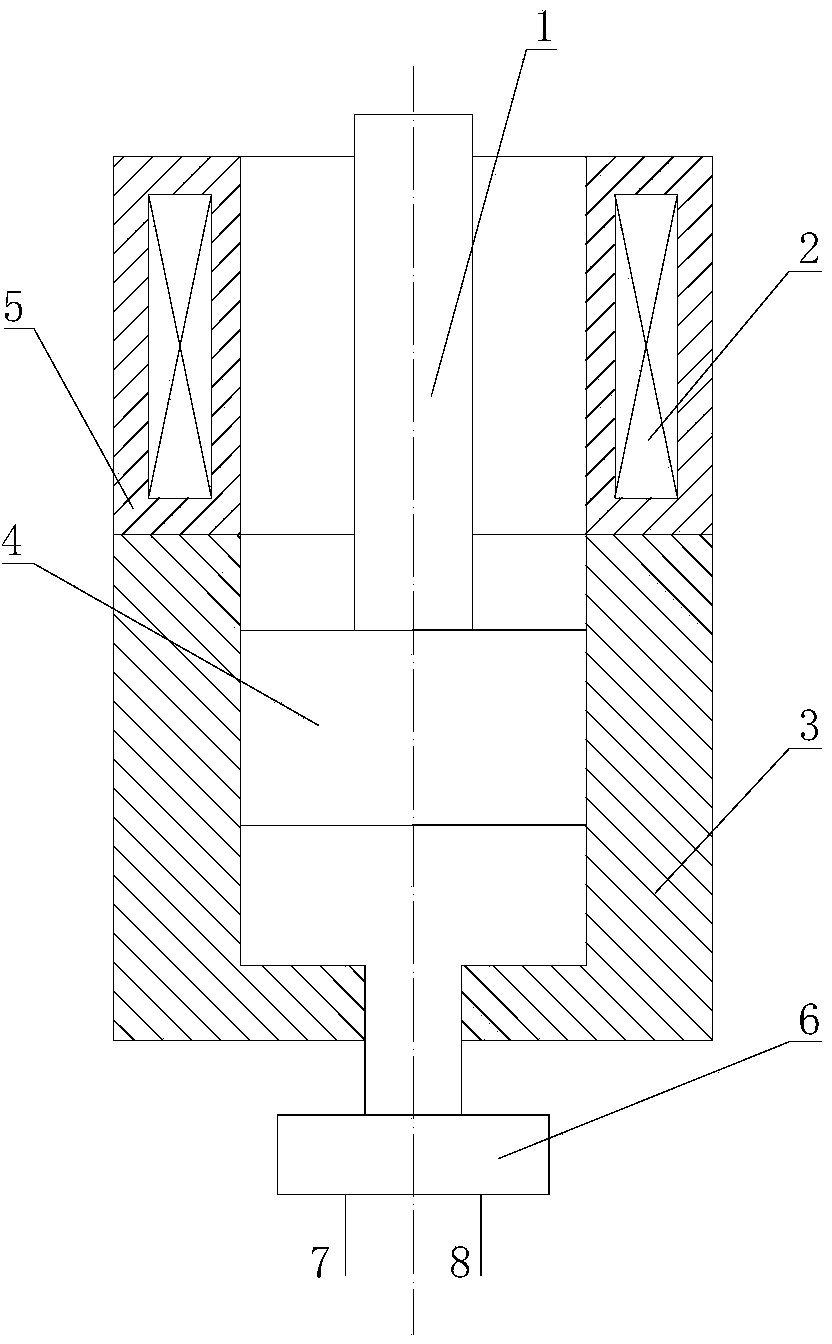

[0011] The main structure of this embodiment includes a mover 1, an electromagnetic coil 2, a cylinder body 3, a plunger 4, a stator 5, a flow distribution system 6, an inlet pipe 7 and an outlet pipe 8; the electromagnetic coil 2 is wound with insulated wires The cylinder body 3 is made of cast iron, alloy cast iron or aluminum alloy according to the needs; the cylinder body 3 is provided with a plunger 4, the mover 1 and the plunger 4 are solidly connected as one, the stator 5 and the cylinder body 4 are solidly connected as one, The stator 5 is provided with an electromagnetic coil 2; the bottom of the cylinder body 3 is provided with a flow distribution system 6, and the bottom of the flow distribution system 6 is provided with an inlet pipe 7 and an outlet pipe 8; the relative linear motion between the stator 5 and the mover 1, the plunger 4 Simultaneously make relative linear motion with the cylinder body 3; the number of plunger 4 is determined according to specific cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com