Automatic coating apparatus

An automatic coating and coating technology, which is applied in the direction of spraying devices, devices for coating liquid on the surface, and processing devices for used abrasives, which can solve problems such as excessive exposure of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

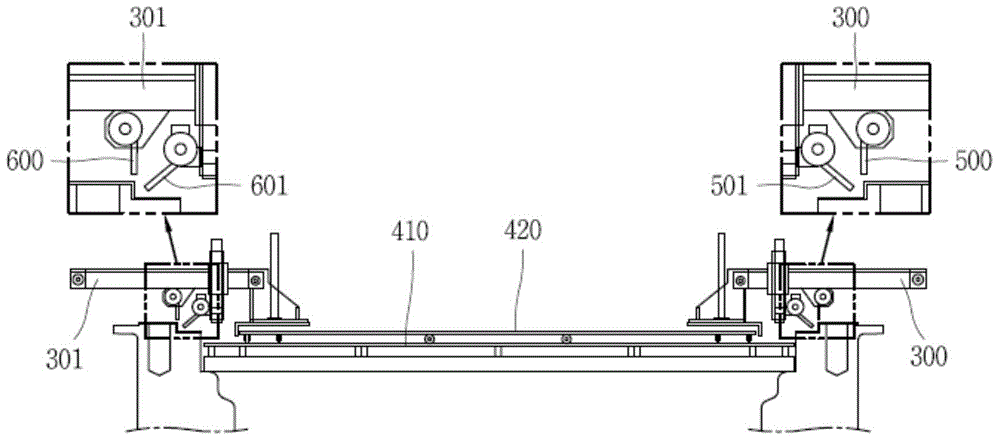

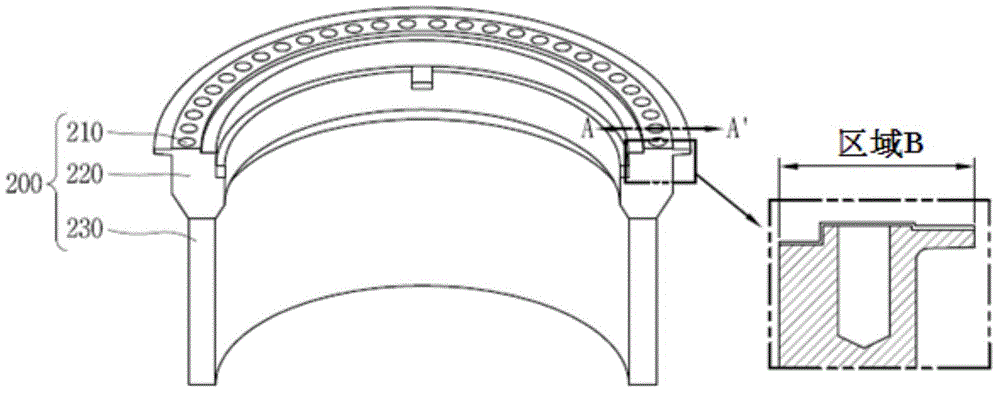

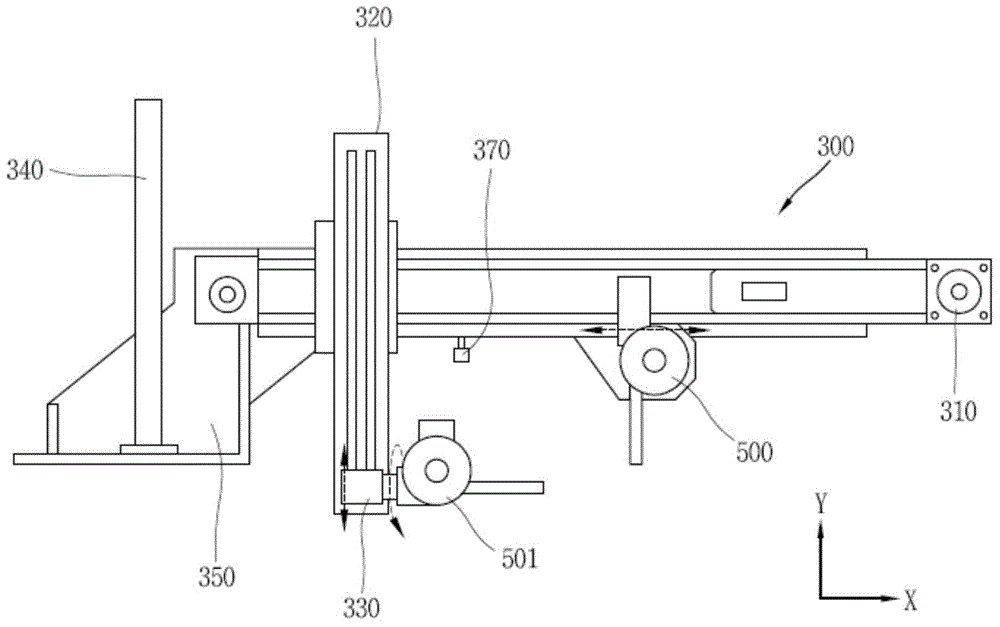

[0025] The automatic coating device according to the present invention will now be described in detail with reference to the accompanying drawings. For the simple description of the specification, the suffix "module" or "part" of the components used in the following description is considered to be only granted or specially mixed and distinguished, and has no meaning or function in itself. As implemented in this specification, similar to the same reference numerals are given to the same and similar embodiments with different configurations. As used herein, unless the context clearly uses otherwise, singular expressions include plural meanings.

[0026] The present invention provides an automatic coating device, which is applied to the flange of the atomic reactor in the atomic power station to remove the corrosion film of the flange and then coat the flange so that no re-corrosion occurs. The automatic coating device is configured for remote control so that it can be operated in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com