Method for preparing silage by using sweet sorghum

A technology of silage and sweet sorghum, which is applied in the field of silage preparation from sweet sorghum, can solve the problems of insufficient lactic acid bacteria in plants, and achieve the effects of avoiding sugar loss, simple operation, and obvious sour flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

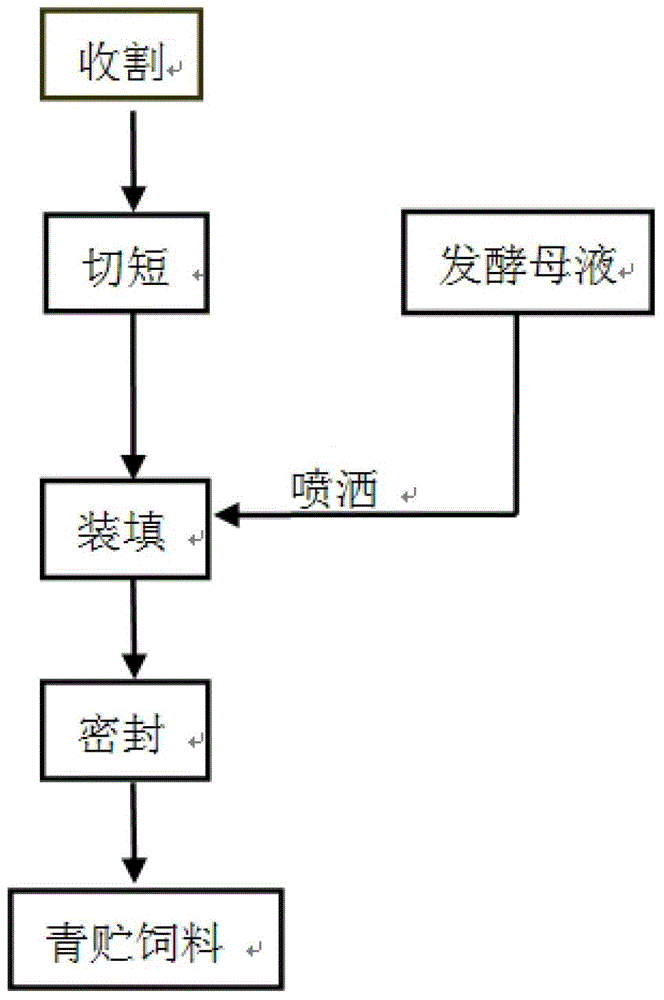

Method used

Image

Examples

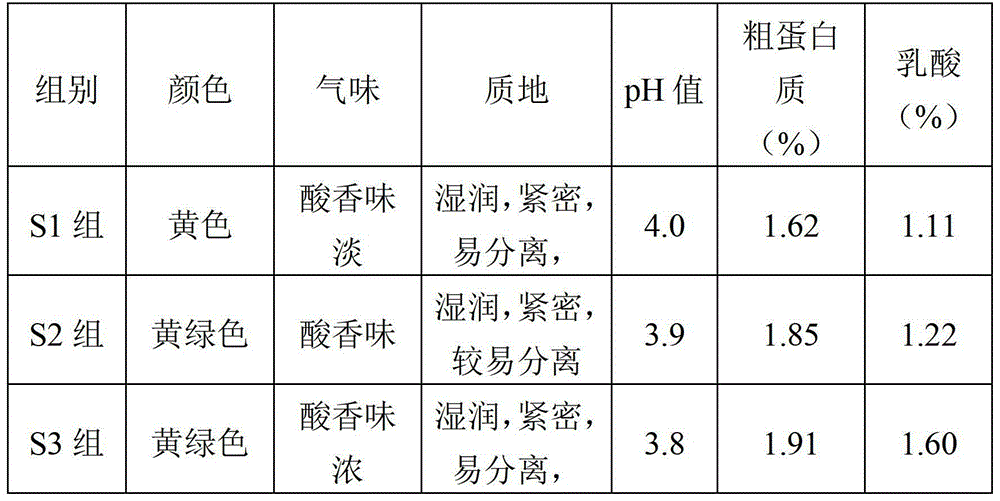

Embodiment 1

[0021] Select the sweet sorghum that has been eared, and harvest it from the ground 8-12cm on a sunny day. The cut sweet sorghum is spread on the spot in the sun for 3 hours and then bundled to reduce the moisture content to 68%. The baled sweet sorghum is transported back as the silage raw material, and the silage raw material is immediately cut into short lengths of 1 cm with a silage chopper. Put the chopped silage raw materials into a plastic bucket with a volume of 20L, fill the silage raw materials layer by layer, the thickness of each layer is 10cm, and spray the prepared lactic acid bacteria fermenting yeast liquid at the same time (from clear water, accounting for clear water 2-3% brown sugar and 0.01% urea in water, at room temperature 23℃~28℃, press 10 8 cfu / L solution inoculated with lactic acid bacteria, fermented and cultured for 4-7 days, and the pH value was reduced to 3.8-4.0) and then tamped with wooden sticks, and 2ml of fermented yeast solution was used fo...

Embodiment 2

[0023] Select the sweet sorghum that has been eared, and harvest it from the ground 8-12cm on a sunny day. The cut sweet sorghum is spread out on the spot for 2 hours and then bundled to reduce the moisture content to 70%. The baled sweet sorghum is transported back as the silage raw material, and the silage raw material is immediately cut into short lengths of 1.5 cm with a silage chopper. Put the chopped silage raw materials into a plastic bucket with a volume of 20L, fill the silage raw materials layer by layer, the thickness of each layer is 15cm, and at the same time spray the prepared lactic acid bacteria fermenting yeast liquid (from clear water, account for clear water 2-3% brown sugar and 0.01% urea in water, at room temperature 23℃~28℃, press 10 8 cfu / L solution inoculated with lactic acid bacteria, fermented and cultured for 4-7 days, and the pH value was reduced to 3.8-4.0) and then tamped with wooden sticks, and 2ml of fermented yeast solution was used for every ...

Embodiment 3

[0025] Select the sweet sorghum that has been eared, and harvest it from the ground 8-12cm on a sunny day. The cut sweet sorghum is spread out on the spot and dried for 1 hour and then bundled to reduce the moisture content to 75%. The bundled sweet sorghum is transported back as the silage raw material, and the silage raw material is immediately cut into short lengths by 2 cm with a silage chopper. Put the chopped silage raw materials into a plastic bucket with a volume of 20L, fill the silage raw materials layer by layer, the thickness of each layer is 25cm, and spray the prepared lactic acid bacteria fermenting yeast liquid at the same time (from clear water, account for clear water 2-3% brown sugar and 0.01% urea in water, at room temperature 23℃~28℃, press 10 8 cfu / L solution inoculated with lactic acid bacteria, fermented and cultured for 4-7 days, and the pH value was reduced to 3.8-4.0) and then tamped with wooden sticks, and 2ml of fermented yeast solution was used f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com