Non-woven material reinforced tissue engineering composite three-dimensional scaffold and preparation method thereof

A non-woven material and tissue engineering technology, applied in medical science, absorbent pads, prostheses, etc., can solve the problems of weak mechanical properties and easy damage of scaffolds, and achieve the effects of convenient processing, promotion of regeneration, and excellent biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

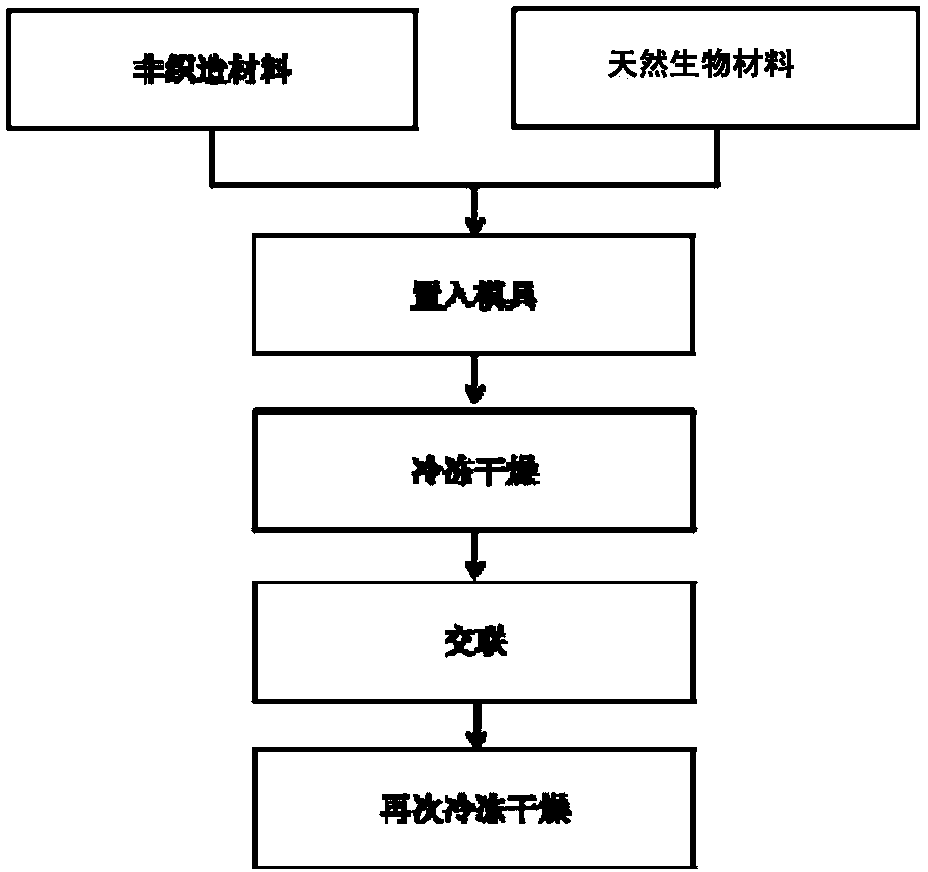

Method used

Image

Examples

Embodiment 1

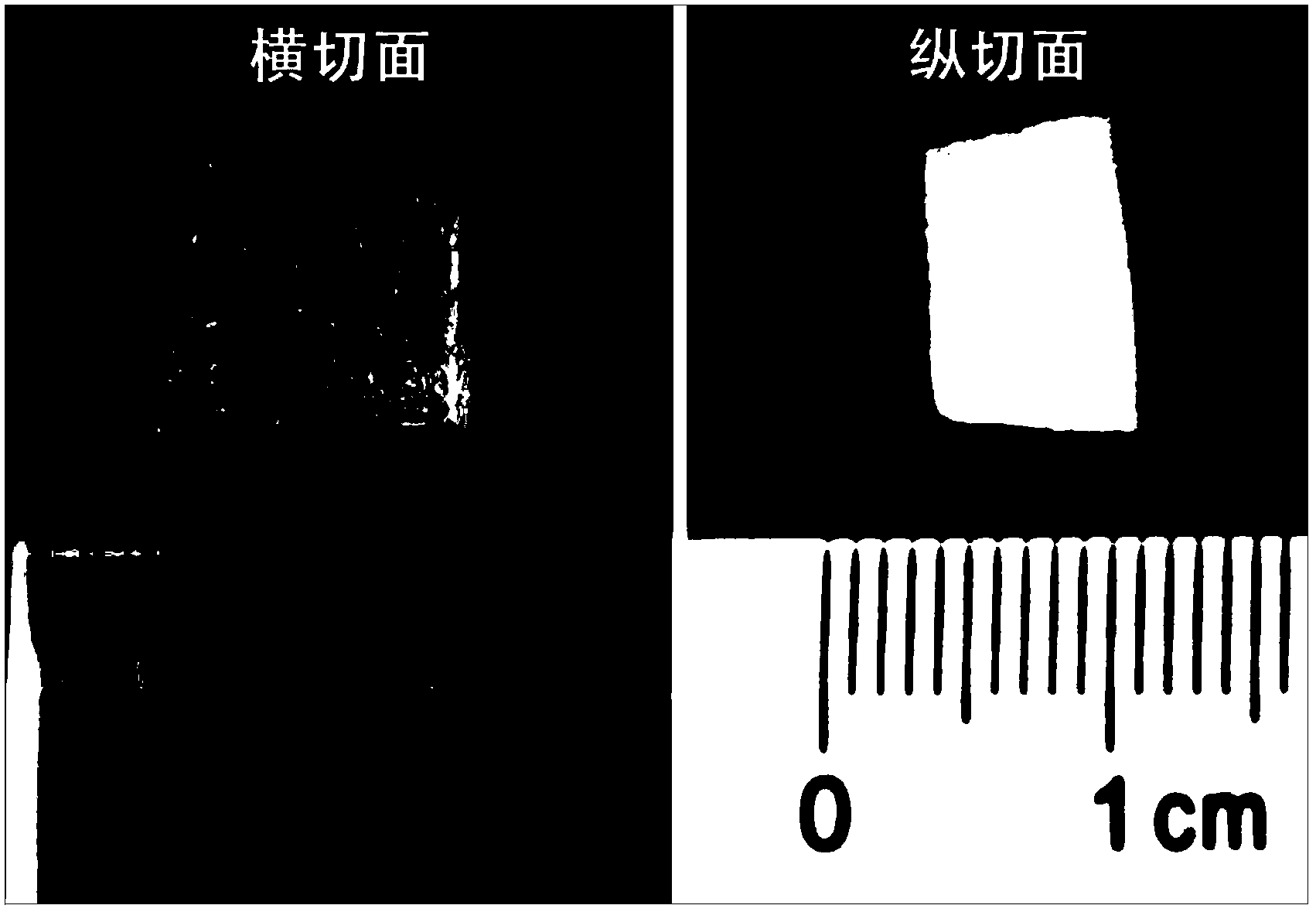

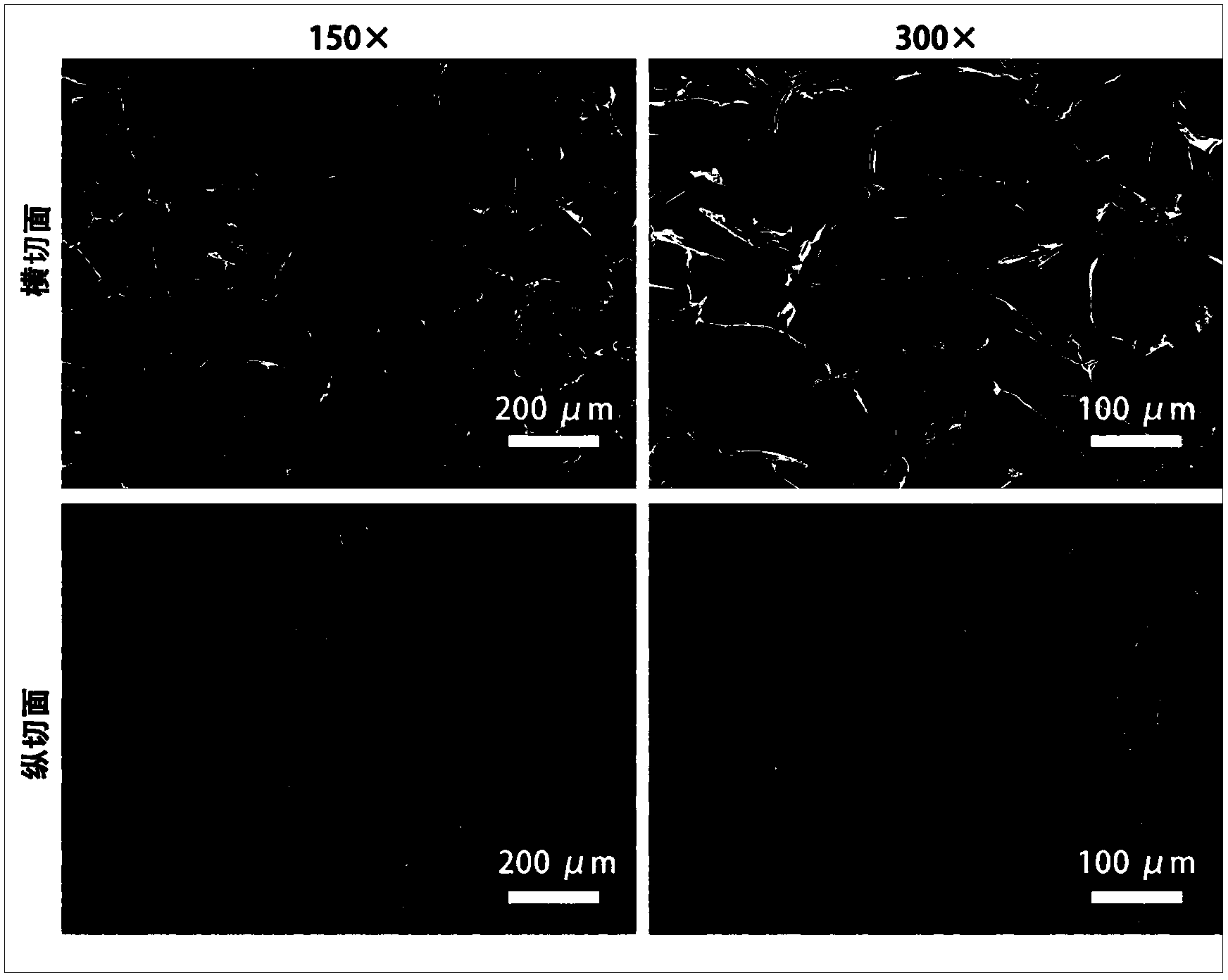

[0037] The regenerated collagen short fibers were carded, laid, and reinforced by acupuncture to prepare a nonwoven material with an area density of 500 g / m2 and a thickness of 5 mm. Dissolve type A fish skin gelatin in deionized water to prepare gelatin solutions with concentrations of 2% and 5%. The regenerated collagen non-woven material is cut into a specified size and put into a plastic mold, and the gelatin solution is injected into the mold to completely immerse the non-woven material. The mold was placed in a -20°C refrigerator for 12 hours, and then freeze-dried using a freeze dryer. Utilize the alcohol solution of EDC / NHS to cross-link the gelatin, the cross-linking time is 12 hours, then wash with deionized water to remove the EDC / NHS, freeze-dry again, and obtain the gelatin three-dimensional scaffold material ( figure 2 ).

Embodiment 2

[0039] The regenerated collagen short fibers were carded, laid, and reinforced by acupuncture to prepare a nonwoven material with an area density of 500 g / m2 and a thickness of 5 mm. Dissolve 0.2 gram of A-type pigskin gelatin and 0.2 gram of silkworm regenerated silk fibroin in 10 ml of deionized water, heat and stir at 60 degrees for 2 hours to completely dissolve the gelatin and silk fibroin, and obtain a concentration of 4%, gelatin / silk fibroin mass ratio It is a 1:1 gelatin / silk fibroin solution. Measure 5 milliliters of gelatin and silk fibroin solution, add 0.05 gram of nano-hydroxyapatite particles therein, with a diameter of 80-120 nanometers, and disperse them evenly by ultrasonic vibration to obtain a nano-hydroxyapatite / gelatin / silk fibroin solution, wherein The mass ratio of each component is 1 / 2 / 2. The regenerated collagen non-woven material is cut into a specified size and put into a plastic mold, and the above two solutions are injected into the mold to compl...

Embodiment 3

[0041]The degummed silk was cut to obtain silk staple fibers, which were carded, laid, and spunlace reinforced to prepare a silk nonwoven material with an area density of 50 g / m2 and a thickness of 2 mm. Dissolve 0.5 g of Bombyx mori regenerated silk fibroin solution in 10 ml of deionized water, and stir to completely dissolve it to obtain a silk fibroin solution with a concentration of 5%. The silk non-woven material is cut into a specified size and put into a plastic mold, and the silk fibroin solution is injected into the mold to completely immerse the non-woven material. Place the mold in a -80 degree refrigerator for 12 hours, and then use a freeze dryer to dry for 48 hours. Soak the cross-linked silk fibroin in 95% alcohol solution for 2 hours, freeze-dry again to remove the alcohol and water, and obtain the silk fibroin three-dimensional scaffold material composited with the silk short fiber non-woven material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com