Drying oven for lithium battery coating machine and drying oven air current control method

A control method and coating machine technology, which are applied to the device, coating, pretreatment surface and other directions of coating liquid on the surface, which can solve the problem of reducing the quality of the lithium battery material coated on the surface of the material belt and affecting the stability of the material belt. It can improve the drying quality and drying efficiency, the airflow is stable, and the heating effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

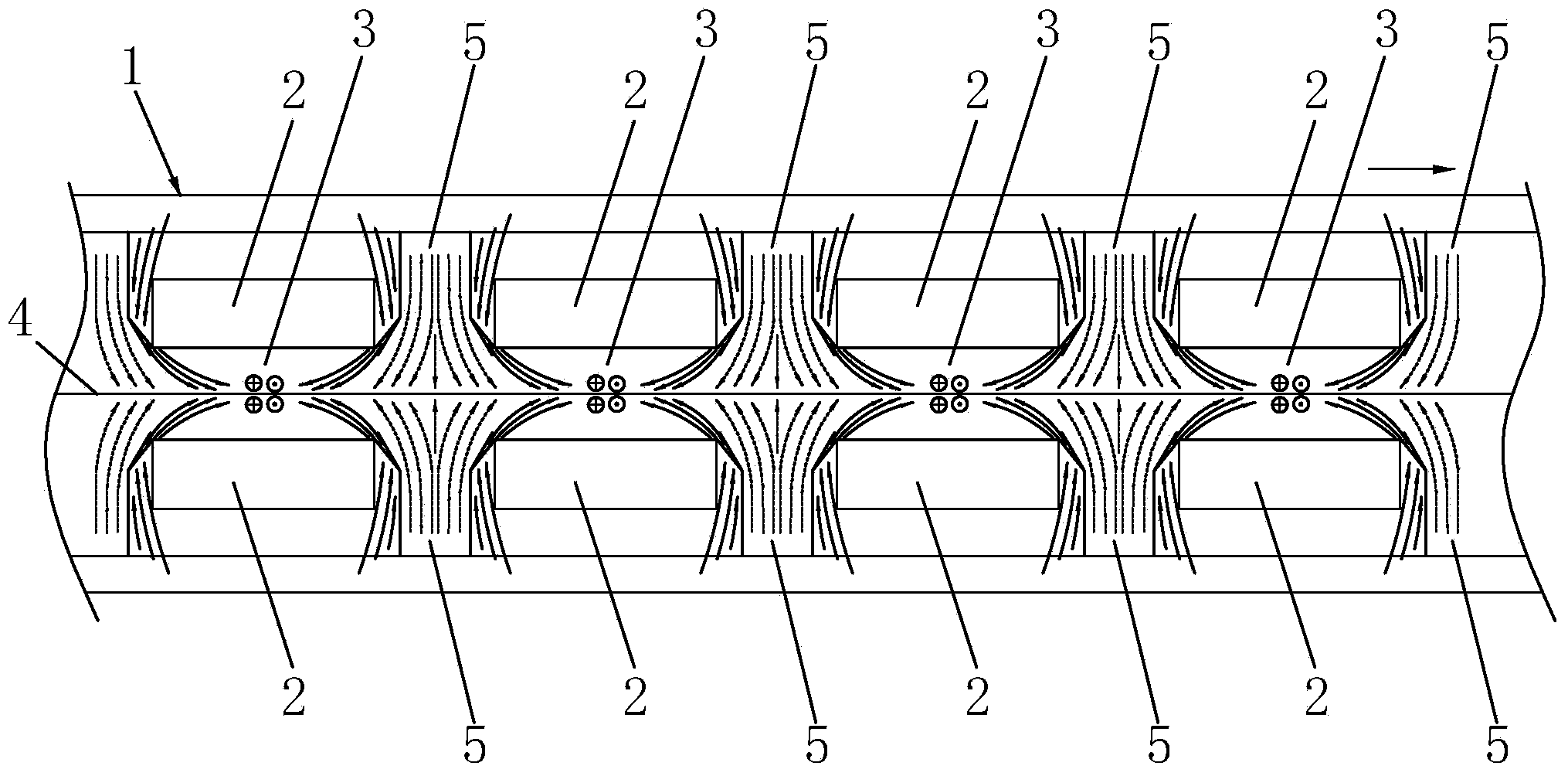

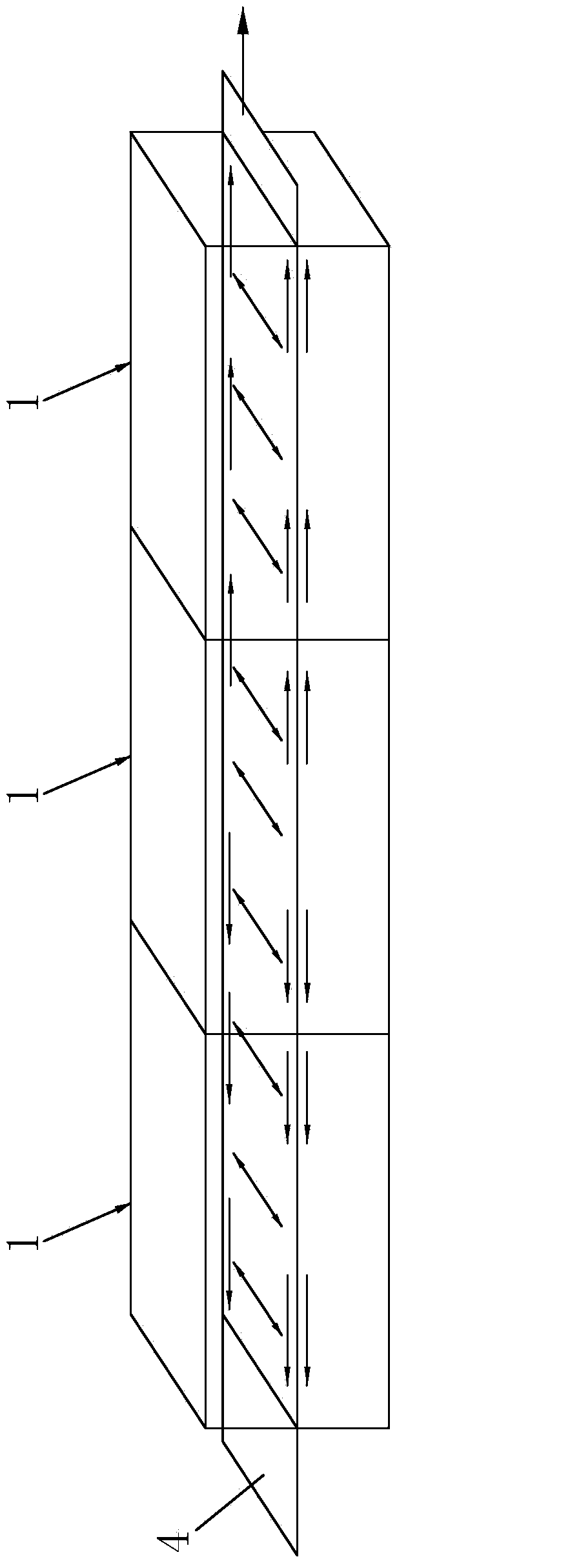

[0030] A method for controlling the oven air flow of a lithium battery coating machine, see Figure 2 to Figure 3 shown, including

[0031] The two rows of air nozzles 2 on the top and bottom of the oven 1 respectively blow hot air to the material tape 4 in the tape running channel 3; the hot air is blown from the air nozzle 2 to dry the material tape 4;

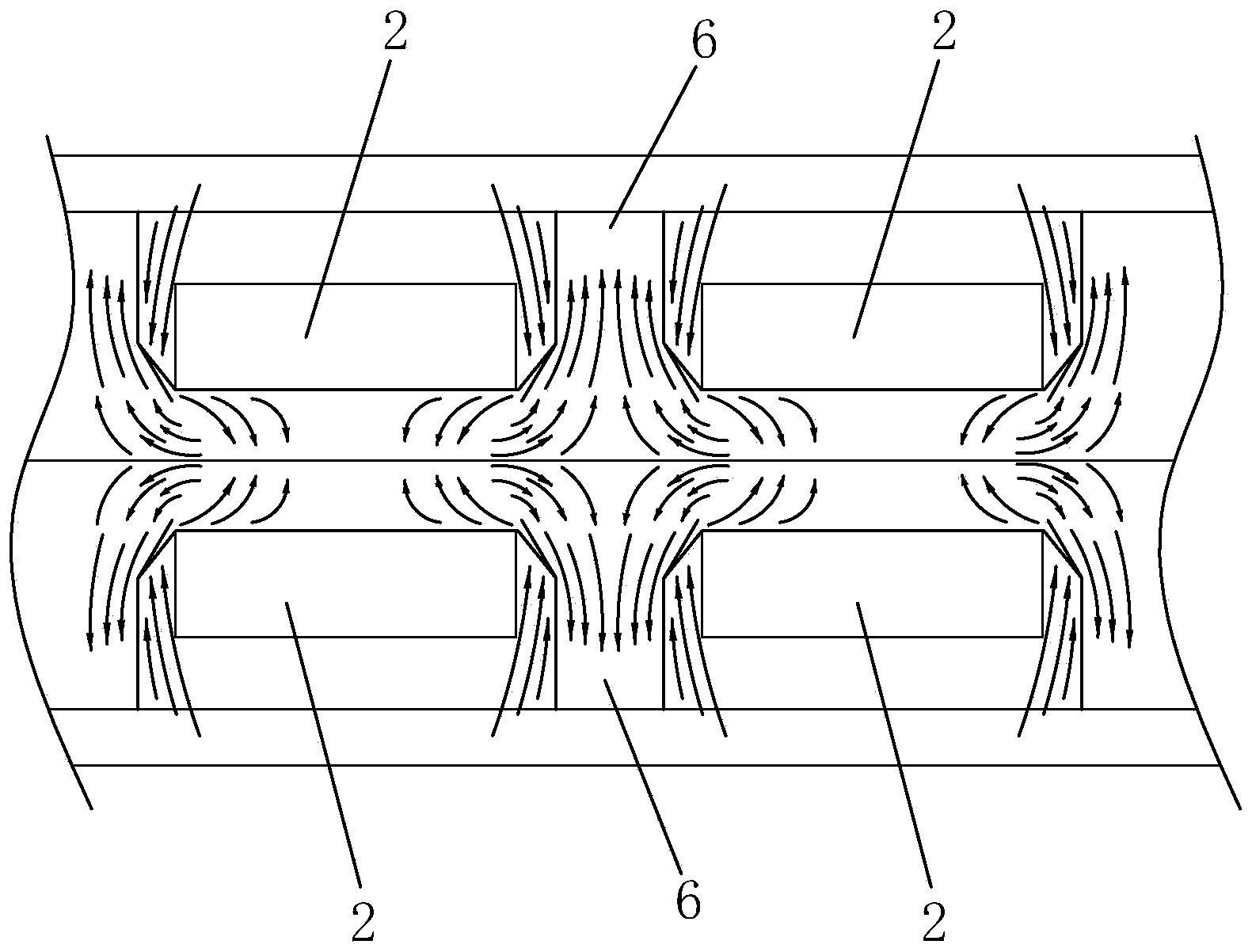

[0032] After the air nozzle 2 blows the hot air to the surface of the strip 4, a negative pressure suction area 5 is formed between two adjacent air nozzles 2;

[0033] The negative pressure suction area 5 between two adjacent air nozzles 2 supplements air or hot air to the surface of the strip 4;

[0034] Along the width direction of the material belt 4, a high-pressure zone is formed in the middle area of the material belt 4, and a low-pressure zone is formed on both sides of the material belt 4; hot air gathered in the high-pressure zone in the middle flows to the low-pressure zones on both sides respectively;

[0035...

Embodiment 2

[0040] A kind of oven of lithium battery coating machine, see Figure 2 to Figure 3 As shown, it includes several sections of ovens 1, and each section of oven 1 is provided with upper and lower rows of air nozzles 2, and between the upper and lower rows of air nozzles 2 is provided with a belt-running channel 3 through which a feeding belt 4 passes. A negative pressure suction area 5 for supplementing air or hot air is arranged between the nozzles 2, and the negative pressure air suction area 5 communicates with external air or a hot air source. Negative pressure air suction ports are respectively arranged on both sides of the air nozzle 2, after the air nozzle 2 blows hot air to the surface of the material tape 4, the negative pressure air suction area 5 supplies air or hot air to the surface of the material tape 4. When hot air is blown out from the tuyere 2, a negative pressure is formed at the negative pressure suction port, and the negative pressure suction port sucks th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com