Water Making Device And Water Making Method

A water production device, seawater technology, applied in the direction of fresh water production devices, water/sewage treatment, chemical instruments and methods, etc., can solve the problem of huge work required for maintenance, and achieve the effect of inhibiting salt and scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

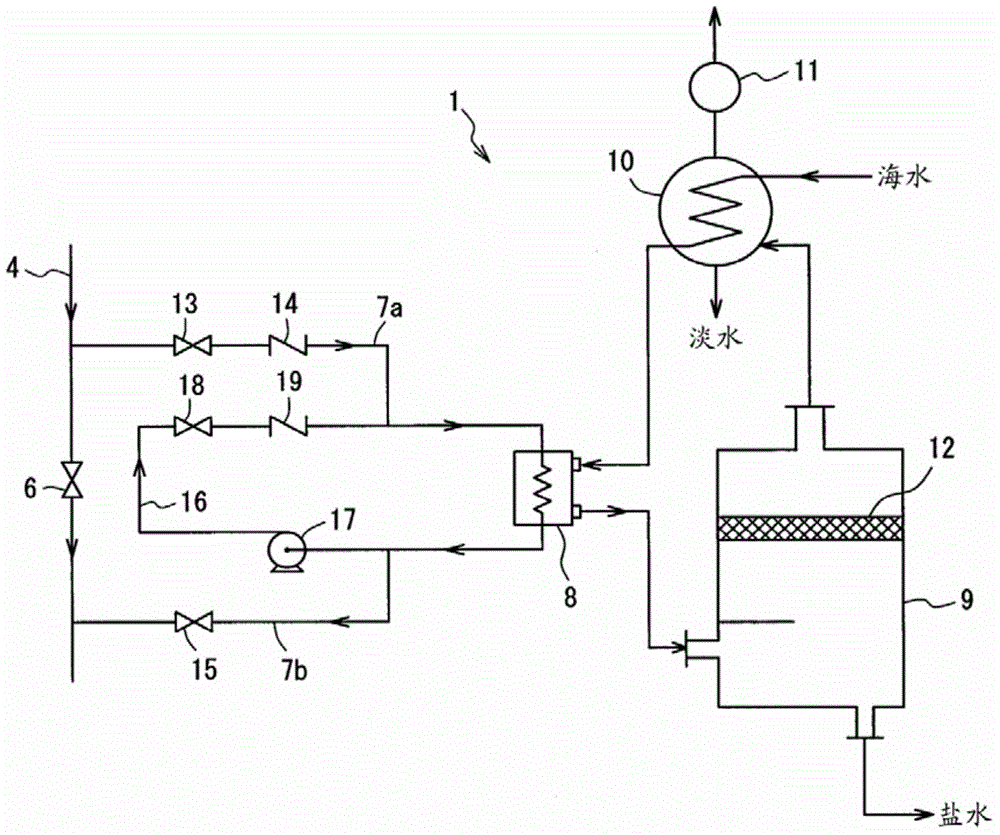

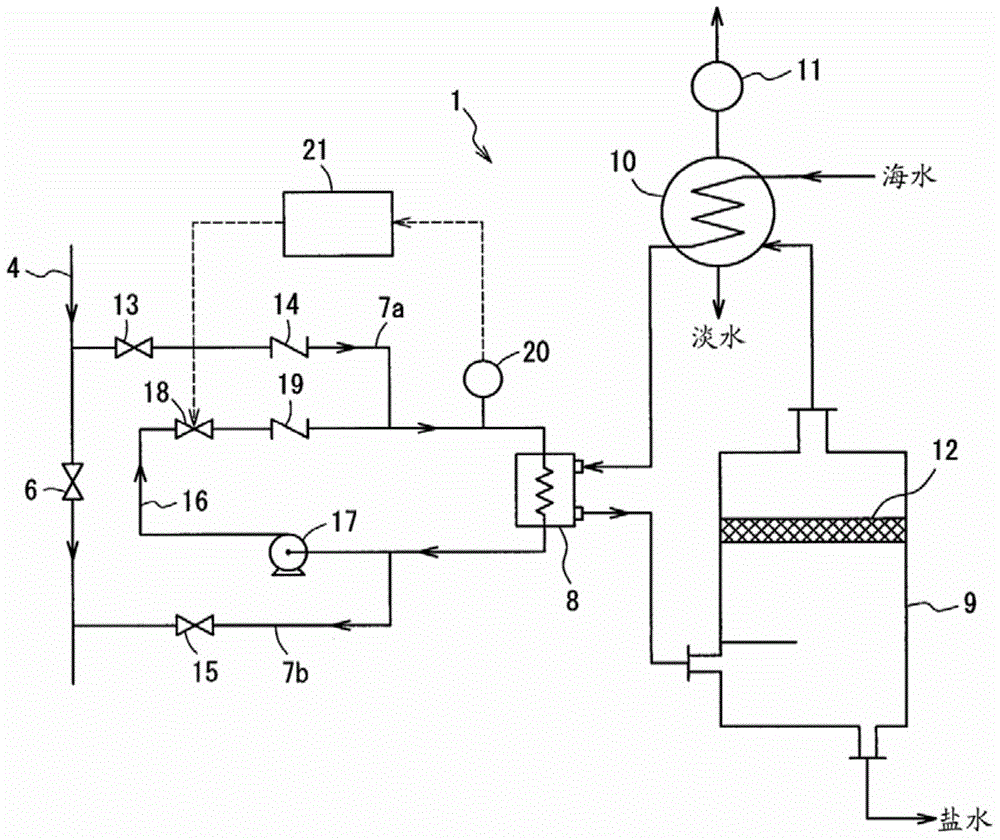

[0028] Embodiments of the present invention will be described in detail below with reference to the drawings.

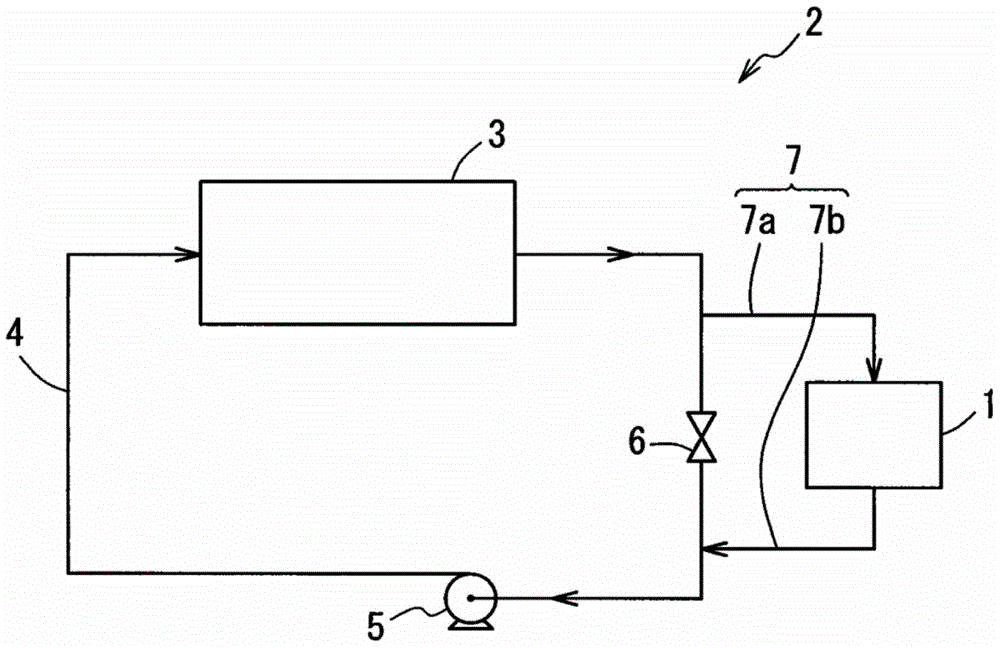

[0029] figure 1 It is a schematic configuration diagram of a system 2 including a water control device 1 according to an embodiment of the present invention.

[0030] The system 2 of this embodiment is mounted on a ship, and includes an internal combustion engine 3 such as a diesel engine, a circulation pipe 4 for circulating and cooling the jacket cooling water of the internal combustion engine 3 , and a circulation pump 5 .

[0031] A first valve 6 is provided in the circulation pipe 4 for cooling the cylinder liner cooling water of the internal combustion engine 3 , and a branch pipe 7 for branching the first valve 6 is connected. The branch pipe 7 includes a forward pipe 7 a for supplying the jacket cooling water from the circulation pipe 4 to the water control device 1 and a return pipe 7 b for returning the cooling water from the water control device 1 to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com