Evaporator for treating oily sewage

An evaporator and oily sewage technology, applied in the field of water treatment, can solve the problems of high equipment installation accuracy, difficult to clean the dirt layer, and reduce heat transfer efficiency, so as to reduce initial investment and operating costs, good social and economic benefits, and improve The effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings. The examples of the present invention are to enable those skilled in the art to better understand the present invention, but do not limit the present invention in any way.

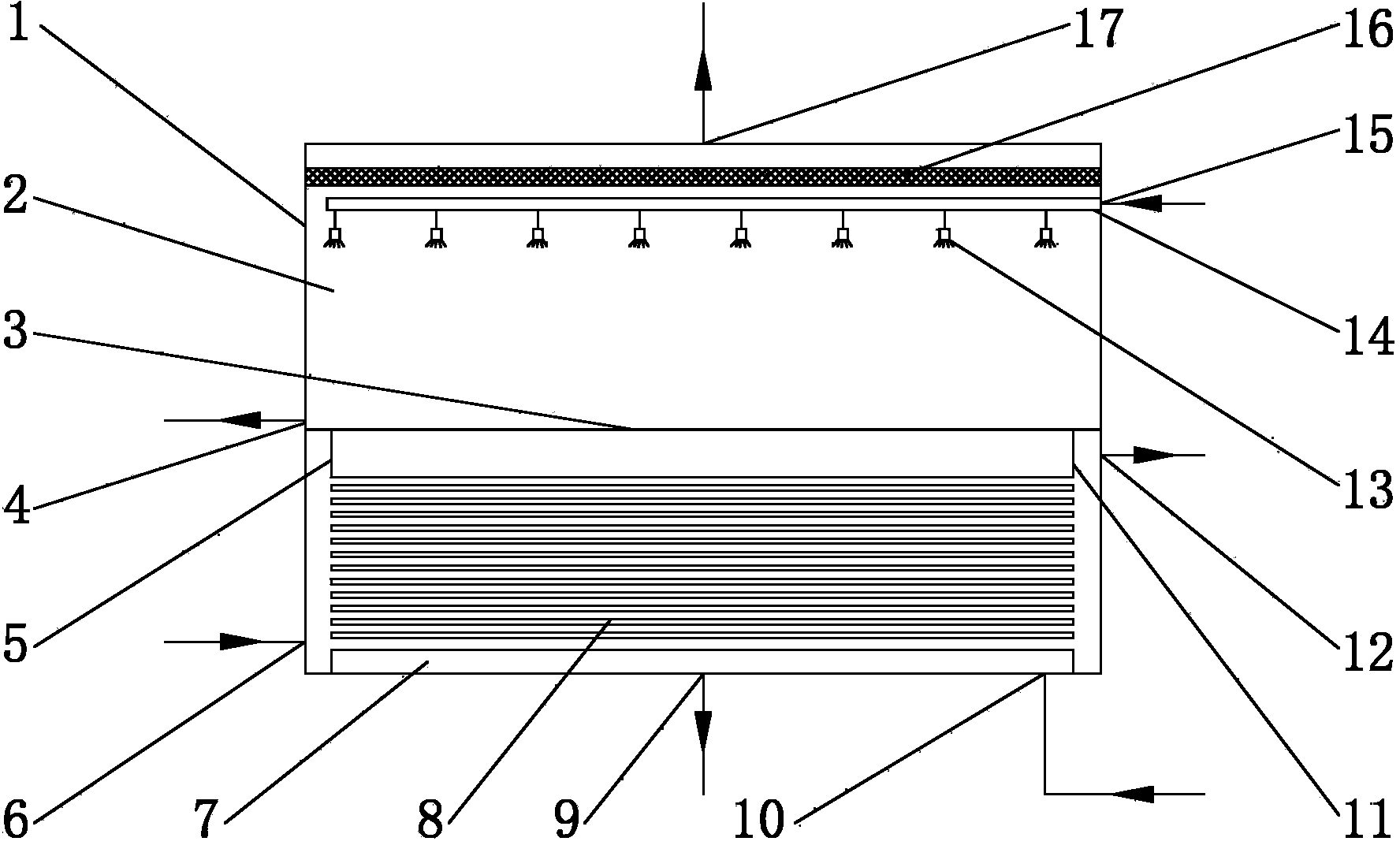

[0028] An evaporator for treating oily sewage, comprising an evaporator shell 1, the middle part of the evaporator shell 1 is fixedly connected with an intermediate partition 3, and the intermediate partition 3 can be welded, bonded, or connected by bolts and rubber pads , the evaporator shell 1 is divided into two completely independent airtight spaces, the evaporation chamber 2 and the condensation chamber 7, and there must be no leakage of liquid or gas between the evaporation chamber 2 and the condensation chamber 7; on the top wall of the evaporation chamber 2 or The upper part of the side wall is provided with a secondary steam outlet 17 and a hot feed liquid inlet 15; a concentrated water outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com