Low-sulfur diesel lubrication anti-wear agent

A technology of low-sulfur diesel oil and anti-wear agent, applied in the field of low-sulfur diesel oil lubricating anti-wear agent and diesel oil additive, can solve the problems of metal corrosion, high cost of raw materials, decreased anti-wear property of diesel oil, etc., to simplify the production process and reduce production. Cost, anti-wear performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

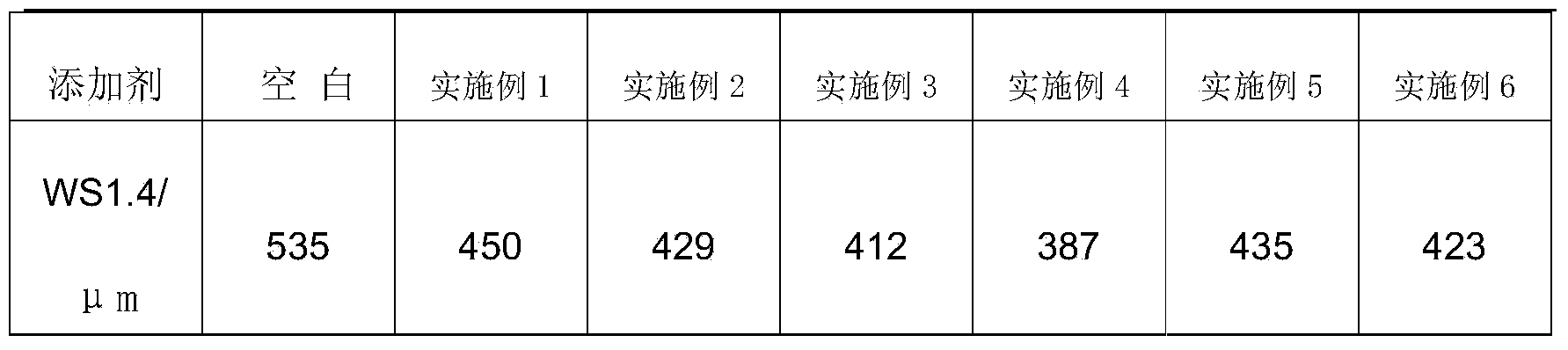

Examples

Embodiment 1

[0026] 1. Take dodecyl salicylic acid, glycerol, titanium butyl ester catalyst, and toluene into the reactor in a mass ratio of 3:1:0.03:0.3, and carry out the esterification reaction according to the preceding steps to obtain twelve Alkyl salicylic acid glyceride; In addition, cetyl salicylic acid, glycerol, titanium butyl ester catalyst, and toluene were added to the reactor at a mass ratio of 3.6:1:0.03:0.3, and the esterification was carried out according to the previous steps Chemical reaction to obtain glyceryl hexadecyl salicylate; add octadecyl salicylic acid, glycerol, titanium butyl ester catalyst, and toluene into the reactor at a mass ratio of 4:1:0.03:0.3 In, the esterification reaction is carried out according to the aforementioned steps to obtain glyceryl stearyl salicylate;

[0027] 2. Take dodecyl salicylic acid, ethylene diamine, and toluene into the reactor at a mass ratio of 5:1:0.5, and carry out the esterification reaction according to the previous steps to ...

Embodiment 2

[0030] Take the glyceryl lauryl salicylate, glyceryl cetyl salicylate, and glyceryl octadecyl salicylate prepared by the method of Example 1 and mix them at a mass ratio of 1:2:1 60 kg of mixed alkyl salicylic acid glycerides were added to the mixing container, and the dodecyl salicylic acid ethylene diamine amide, cetyl salicylic acid ethylene diamine amide, and octadecyl salicylic acid amide prepared by the method in Example 1 Alkyl salicylic acid ethylene diamine amide is mixed at a mass ratio of 1:2:1, and 30 kg of mixed alkyl salicylic acid ethylene diamine amide is added to the mixing container, and then 10 kg of D60 solvent oil is added to the mixing container , Stir evenly to obtain low-sulfur diesel lubricating and anti-wear products.

Embodiment 3

[0032] Take the glyceryl lauryl salicylate, glyceryl cetyl salicylate and glyceryl octadecyl salicylate prepared by the method of Example 1 and mix them at a mass ratio of 1:2:1 67 kg of mixed alkyl salicylic acid glycerides were added to the mixing container, and the dodecyl salicylic acid ethylenediamine amide prepared by the method of Example 1 Alkyl salicylic acid ethylene diamine amide is mixed according to the mass ratio of 1:2:1, and 23 kg of mixed alkyl salicylic acid ethylene diamine amide is added to the mixing container, and then 10 kg of D60 solvent oil is added to the mixing container. , Stir evenly to obtain finished products of low-sulfur diesel oil lubricating and antiwear agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com