Aluminum Component Repairing Method, Repairing Liquid, Aluminum Material And Manufacturing Method Of The Aluminum Material

A technology of repair method and manufacturing method, which is applied in the direction of electrolytic coating, surface reaction electrolytic coating, coating, etc., and can solve problems affecting painting or other parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

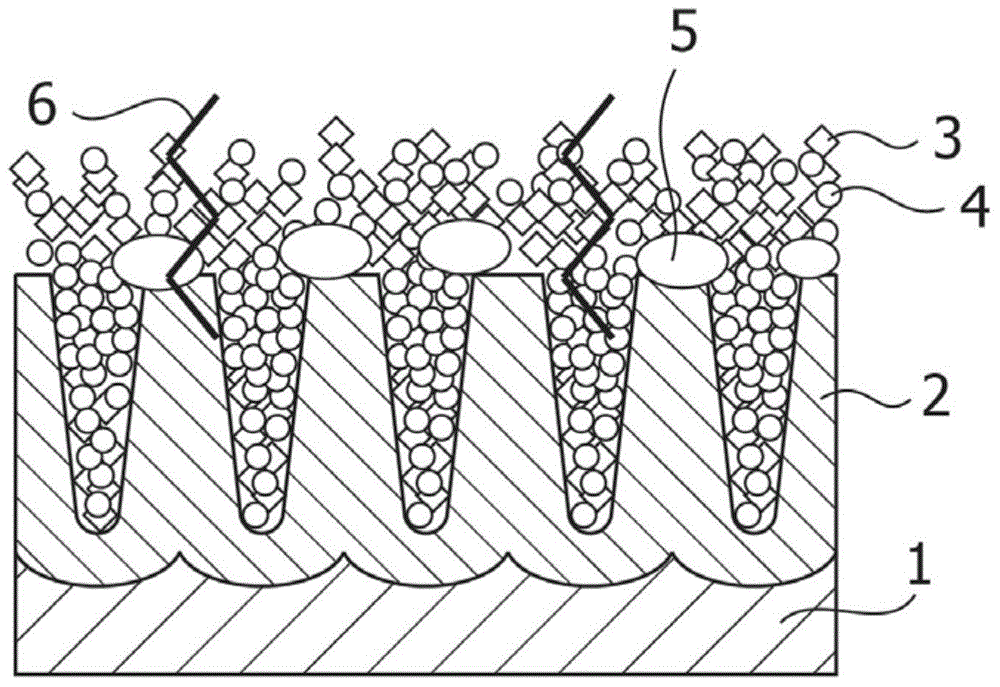

Method used

Image

Examples

Embodiment 1

[0095] An aluminum alloy (ADC12 material), which will be an aluminum-based material, was used as a test piece. Immerse the test piece as an anode in a 200g / L sulfate bath, and at 1.5A / dm 2 A direct current was applied at a current density of 10 minutes to form an anodized film having a thickness of 3 μm. After the anodized film was formed, the test piece was immersed in a sealing solution containing 0.8 g / L of lithium ions and having a pH of 12 and a temperature of 40° C. for 1 minute to perform sealing treatment. Thereafter, assuming baked coating, the test piece was heated in an oven at a temperature of 150° C. for 30 minutes to generate cracks in the anodized film. After the cracks are formed, the test piece is immersed in an aqueous solution of sodium chloride containing 1.0 mol / L of sodium ions as an alkali metal and having a temperature of 50 ° C and a pH value of 7 for 15 minutes to 24 hours to perform repairing treatment. Wash with water, then dry by blowing. Whethe...

Embodiment 41

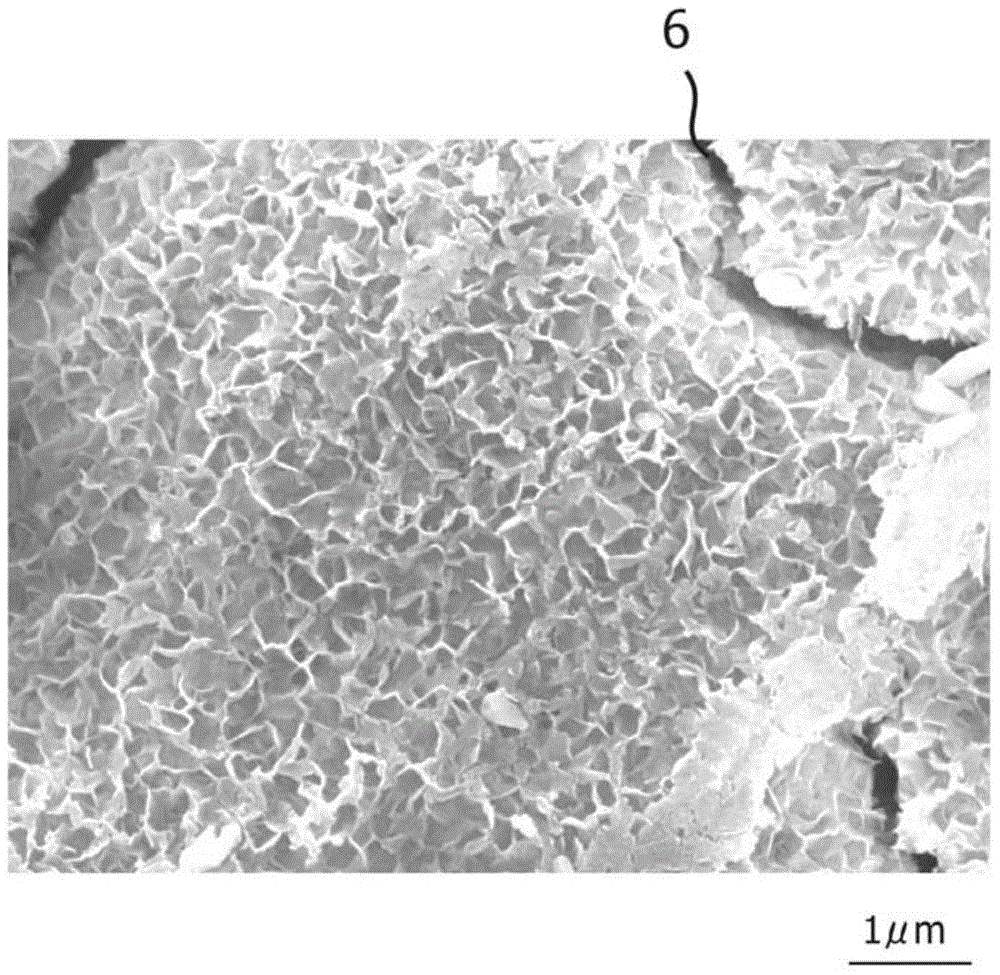

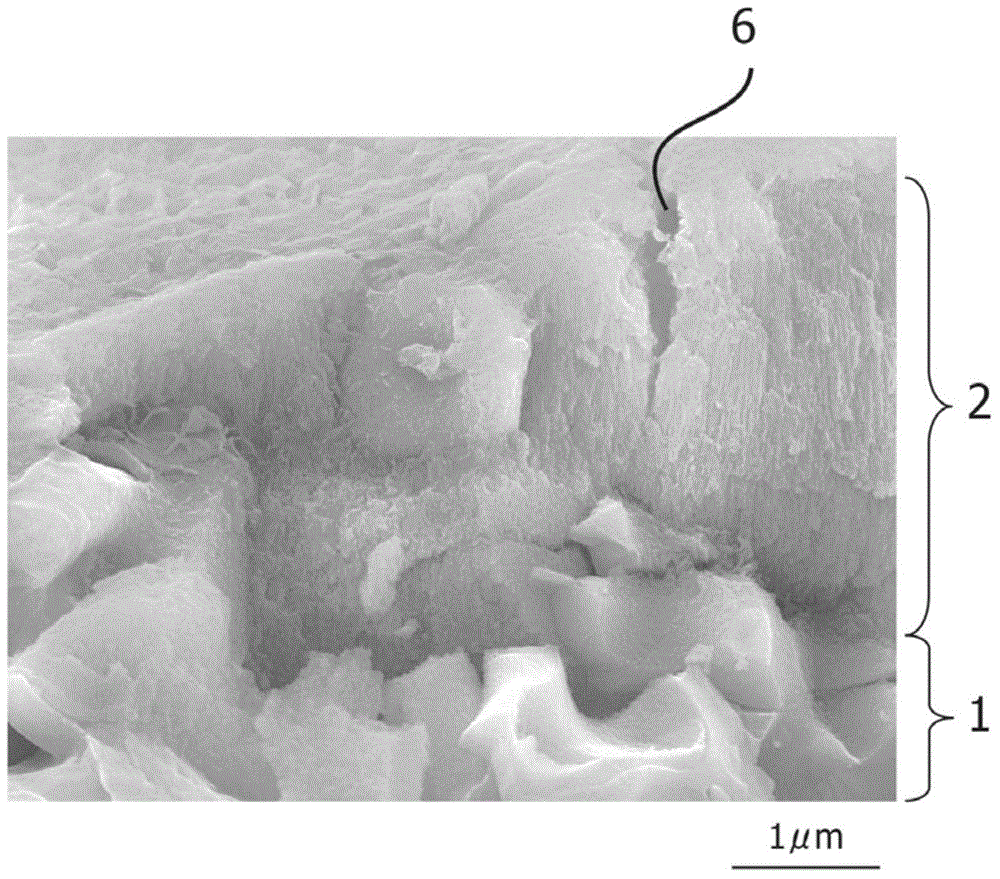

[0116] The aluminum alloy (ADC12 material) used as the test piece was anodized and sealed by the same treatment as in Example 1. Thereafter, assuming that the test piece was damaged by assembling the parts, the test piece was scratched by a cutting machine so that the scratch reached the ADC12 material, and then the test piece was subjected to a temperature of 25° C. and Sodium chloride aqueous solution with a pH value of 7 was immersed for 120 hours for restoration treatment. After the restoration treatment, the aluminum alloy was washed with water in the same manner as in Example 1 and then dried by wind. After drying, the surface of the damaged portion was observed with the naked eye, and the cross-section of the damaged portion was observed by FE-SEM to evaluate whether the wound was repaired or not. Figure 18 Photographs of the surface of the test piece before and after the restoration step and metallographic micrographs of the section of the test piece are shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com