A bushing centering locator and its working method

A working method and locator technology, which is applied in the field of casing centering locator and well completion equipment, can solve the problems of poor centralization effect, easy to be blocked, small centralization force of elastic centralizer, etc., achieve moderate length, improve stability and function force, on-site connection and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

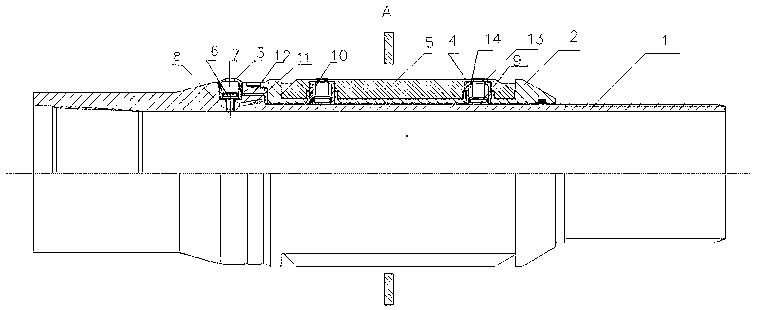

[0023] Such as figure 1 As shown, a half-sectional view of a sleeve centering locator of the present invention. It includes a casing body 1 and a wing plate control system 2. The casing body 1 is provided with an internal thread at one end and an external thread at the other end; the wing plate control system 2 includes a hydraulic locking mechanism 3 and a wing plate driving device 4 A liquid channel 10 is provided between the locking device 3 and the wing plate driving device 4 and the centralizing wing plate 5; the wing plate control system 2 is embedded on the outside of the casing body 1, and the wing plate control system 2 and the casing body 1 A radial through hole 8 is arranged between the inner cavities; the centralizing wing plate 5 and the wing plate driving device 4 are connected by screws.

[0024] The hydraulic locking mechanism 3 includes a hydraulic control valve 6, a hydraulic control valve cavity 7, a liquid inlet channel 11 and a liquid return channel 12; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com