Flexible screw

A kind of screw and flexible technology, applied in the direction of belt/chain/gear, mechanical equipment, transmission device, etc., can solve the problems of limited screw stroke control, short adjustable distance, complex structure, etc., to achieve good torsion resistance, The effect of enhancing torsion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

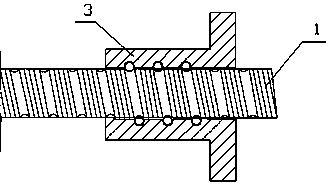

Method used

Image

Examples

Embodiment 1

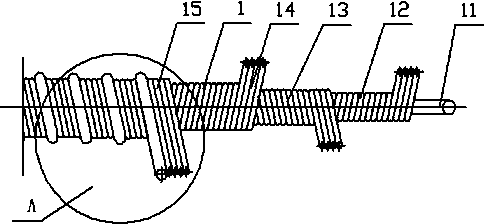

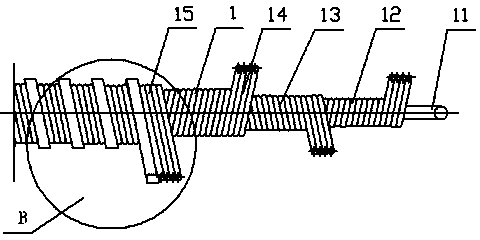

[0040] Example as image 3 , Image 6 , Figure 8 As shown, the threaded thread 17 is round, and the elastic thread is round, which is the most common round thread wound. The cross-section of the threaded thread is circular, and its diameter is larger than that of the elastic thread. The threaded thread forms a continuous spiral guideway on the surface of the flexible threaded rod.

Embodiment 2

[0041] Example two such as Figure 4 , Figure 7 with Figure 9 As shown, the cross-sectional shape of the thread 17 is drum-shaped or rectangular, and the upper and lower ends are flattened or ground. Compared with the thread with circular cross-section, the strength of rectangular and drum-shaped thread is better, and the internal thread of the matching screw pair is easier to process and has better wear resistance.

Embodiment 3

[0042] Embodiment three such as Figure 10 As shown, the cross-sectional shape of the thread is a triangular thread 20, which is more suitable for a flexible screw rod with denser thread and smaller spacing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com