Rapid detection method for beta vulgaris quality

A detection method and sugar beet technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of cumbersome price, time-consuming operation, high cost, etc., and achieve the effect of simple operation, low power consumption, and saving money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

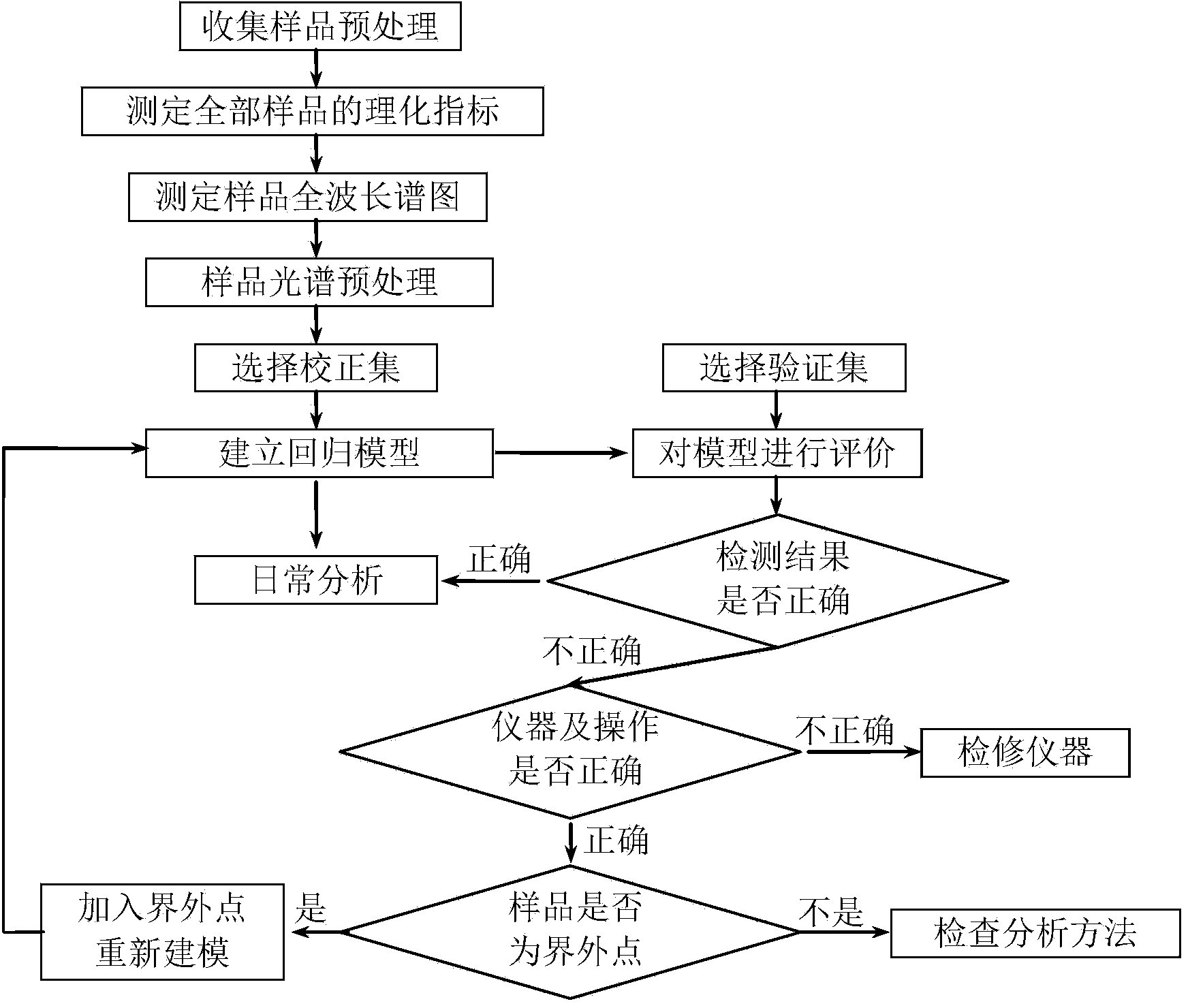

[0038] Example 1 Establishment of regression model

[0039] The establishment of partial least squares regression model of sugar beet quality detection index and near-infrared characteristic wavelength spectrum is as follows:

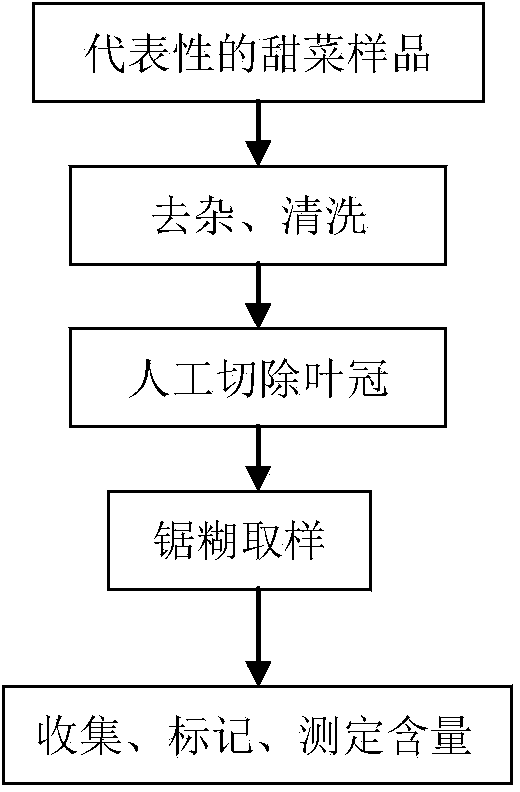

[0040] 1. Collect a total of 380 samples of 28 varieties of sugar beet, and put them in a sample bag after being sawed and paste.

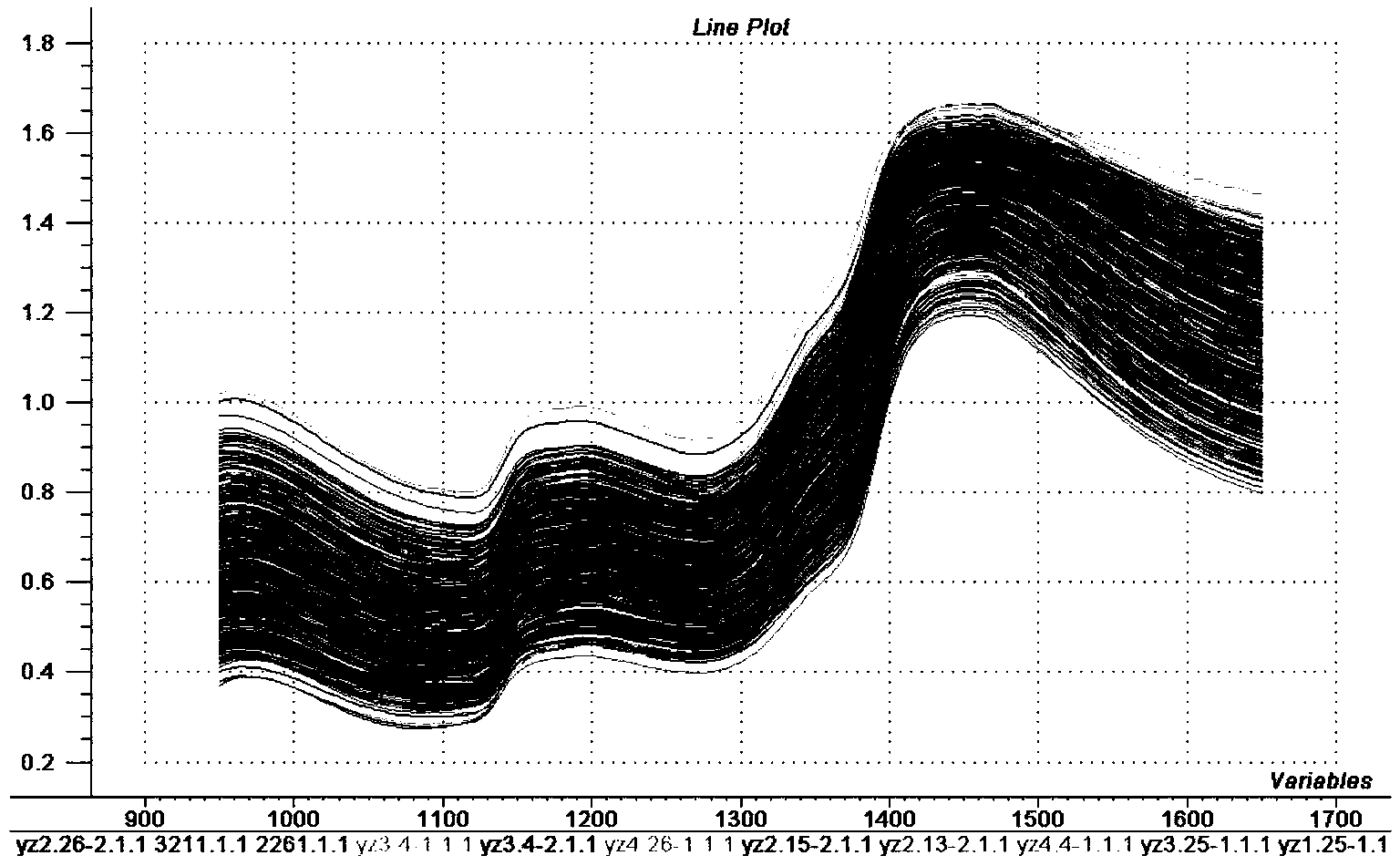

[0041] The sample will be pretreated (see figure 2 ) The beet saw paste samples are evenly spread in a sample cup with a diameter of 75mm, and scanned 60 times with a resolution of 5nm using a near-infrared analyzer. The temperature of the sample and the environment are both 20±2℃, and the spectral scanning range is 900~1700nm. , Get the near-infrared scanning spectrogram, see the original picture image 3 . Repeat the sample loading measurement twice to maintain the uniformity of the sample loading and obtain the average spectral curve.

[0042] 2. Perform the first derivative (FD), standard normal variable transformation (SNV),...

Embodiment 2

[0045] Example 2 Quality inspection of samples to be tested

[0046] Based on the regression model established in Example 1, quality testing and grading of 70 samples to be tested were performed, and the steps were as follows:

[0047] 1. Pretreatment of the sample to be tested (e.g. figure 2 );

[0048] 2. Spectral scanning of the sample to be tested by the near-infrared analyzer;

[0049] 3. The test results of the sugar content index of the sample to be tested are shown in Table 1.

[0050] Table 1 Comparison of the predicted value of sugar content of sugar beet samples with the measured value of traditional methods

[0051]

[0052]

[0053] One-way analysis of variance results P = 0.9549, r = 0.9599, SEP = 0.439, Bias = 0.023

[0054] From the above analysis results, it can be seen that there is no significant difference between the predicted value of the near-infrared sugar content model and the laboratory true value (P = 0.9549), the correlation between the two sets of data is goo...

Embodiment 3

[0055] Example 3 Establishment of a near-infrared detection model for large sugar beet particles

[0056] The establishment of partial least squares regression model of sugar beet quality detection index and near-infrared characteristic wavelength spectrum is as follows:

[0057] 1. A total of 115 representative sugar beet samples were selected, and they were made into large sugar beet particles and then packed in a sample bag for uniform numbering, and spectral scanning was used for standby.

[0058] Obtaining large beet particles: clean the beet sample, remove the leaf crown, and evenly cut it into 2mm*2mm*2mm particles. Spread the sugar beet particle sample evenly in a sample cup with a diameter of 75mm, and use a near-infrared analyzer to scan 60 times with a resolution of 5nm. The temperature of the sample and the environment are both 20±2℃, and the spectral scan range is 900~1700nm. A near-infrared scan spectrum is displayed. Repeat the sample loading measurement twice to mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com