High-accuracy synchronous multi-measurement-ruler based semiconductor laser distance measurement device and method

A high-precision synchronization and laser ranging technology, applied in measuring devices, radio wave measuring systems, using re-radiation, etc., can solve problems such as lack, achieve increased flexibility, improve measurement efficiency and accuracy, and overcome the indirectness of measuring rulers. The effect of traceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

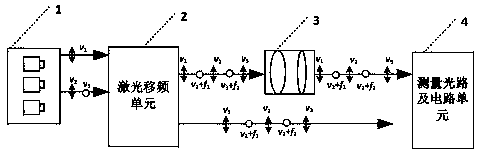

[0034] A semiconductor laser ranging device based on high-precision synchronous multi-measurement rulers, including a beam expander collimator mirror group 3, the device is composed of a ruler generation unit 1, a laser frequency shift unit 2, a beam expander collimator mirror group 3 and a measurement Composed of optical path and circuit unit 4, the laser emitted by the measuring ruler generating unit 1 is output to the input end of the laser frequency shifting unit 2, and a laser output from the laser frequency shifting unit 2 is output to the measuring optical path and circuit unit through the beam expanding collimating lens group 3 4, another laser output from the laser frequency shifting unit 2 is directly input to the other input end of the measurement optical path and circuit unit 4;

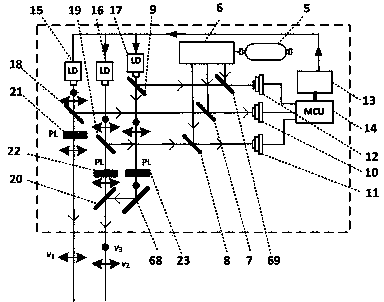

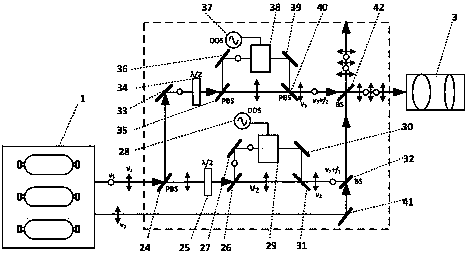

[0035] The structure of the measuring ruler generation unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com