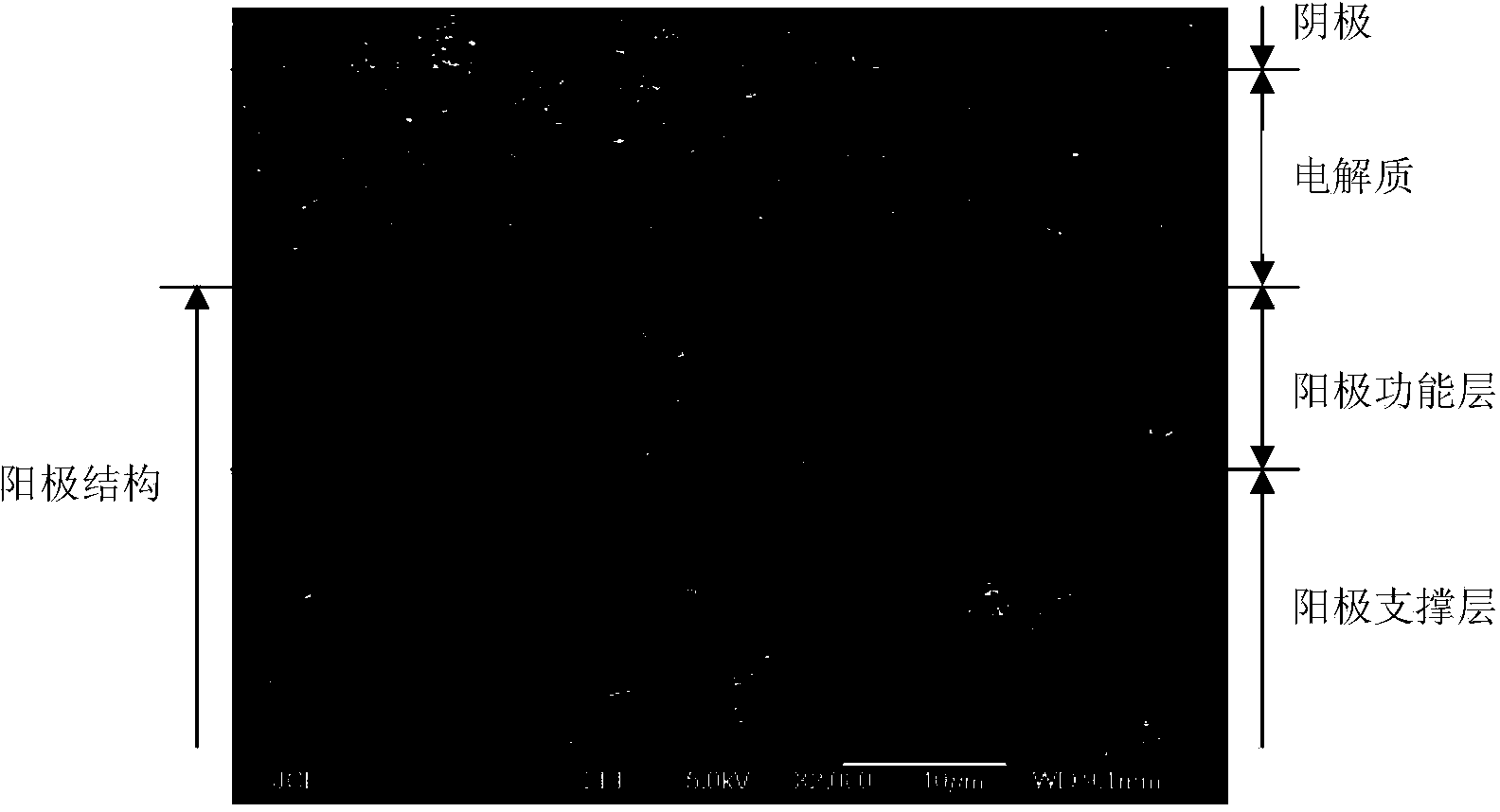

Medium-temperature SOFC (solid oxide fuel cell) flat-plate anode-supported monocell anode structure and preparation method thereof

An anode-supported, anode-structured technology, applied in battery electrodes, structural parts, solid electrolyte fuel cells, etc., can solve problems such as large amount of raw materials, low battery mechanical strength, and anode performance degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Preparation of medium-temperature SOFC planar anode-supported single-cell anode structure:

[0048] (1) Preparation of water-based anode functional layer slurry (moisture content 38wt%): wherein, NiO:8YSZ is 50:50 by weight, the particle size of the powder before sintering is 0.35 μm, and the particle size of the two powders is basically the same; The pore forming agent is monodisperse spherical polymethyl methacrylate (PMMA), the pore diameter of the pore forming agent is about 1.8 μm, and its dosage is 5wt% of the total mass of NiO and 8YSZ; the anode functional layer is cast by a tape casting process Thickness of film green sheet, after drying at 30°C for 10 minutes, is 30 μm;

[0049] (2) Preparation of water-based anode support layer slurry (moisture content 35wt%): wherein, NiO:5YSZ is 60:40 weight ratio, and the particle size of the powder before sintering is 0.7 μm, and the particle size of the two powders is basically the same, Its pore-forming agent is monodi...

Embodiment 2

[0058] Preparation of medium-temperature SOFC planar anode-supported single-cell anode structure:

[0059] (1) Preparation of water-based anode functional layer slurry (water content 40wt%): wherein, NiO:8YSZ is 45:55 by weight, the particle size of NiO powder before sintering is 0.15 μm, and the particle size of 8YSZ powder is 0.25 μm ; The pore-forming agent is polymethyl methacrylate (PMMA), monodisperse spherical, the pore-forming agent has a pore diameter of about 3.0 μm, and its amount is 3.0wt% of the total mass of NiO and 8YSZ. The anode functional layer film green sheet was cast by casting process, and the thickness was 36 μm after drying at 60°C for 5 minutes;

[0060] (2) Prepare the water-based anode support layer slurry (water content 36wt%), the proportion is NiO:3YSZ is 55:45 weight ratio, the particle size of the NiO powder before sintering is 0.6 μm, and the particle size of the 3YSZ powder is 0.8 μm, its pore forming agent is methyl methacrylate (PMMA), mono...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com