Transformer primary side series connection LLC and output parallel connection BUCK two-stage converter

A transformer secondary side, transformer technology, applied in the direction of output power conversion device, DC power input conversion to DC power output, instruments, etc., can solve the problem of reducing module output load characteristics, complex control system design, and the current sharing bus is susceptible to interference and other issues, to achieve reliable and efficient synchronous rectification, simplify the control link, and reduce the effect of EMI radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

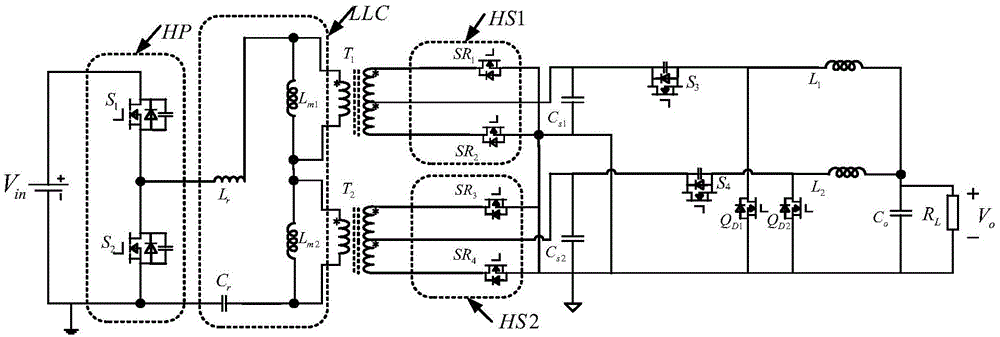

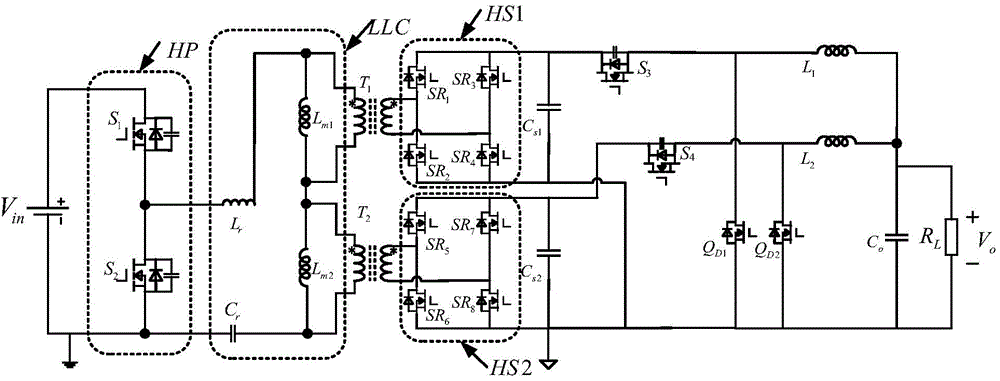

[0024] Such as figure 2 As shown, as the second embodiment of the present invention, the main circuit is composed of a front-stage fixed-frequency half-bridge LLC resonant converter and a rear-stage output terminal interleaved parallel BUCK circuit, wherein the front-stage fixed-frequency half-bridge LLC resonant converter consists of one Half-bridge bridge circuit HP, a resonance network LLC, two high-frequency isolation transformers T1, T2, two rectifier circuits HS1, HS2, and two bus capacitors Cs1 and Cs2. The half-bridge circuit HP is composed of switching tubes S1 and S2. The resonance network LLC is composed of a series resonance inductance Lr, the excitation inductances Lm1 and Lm2 of two high-frequency transformers, and a series resonance capacitor Cr. HS1 is composed of synchronous rectifier tubes SR1 and It is composed of SR2, SR3, and SR4, and HS2 is composed of synchronous rectifier tubes SR5, SR6, SR7, and SR8. Among them, the drain of the switch S1 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com