heated lamp cover

A lamp cover and polymer technology, applied in heating elements, ohmic resistance heating, lighting and heating equipment, etc., can solve the problems of damaged heating wire connection, heating function failure, and easy failure of electrical contact parts, etc., to achieve stable electrical contact , to avoid the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

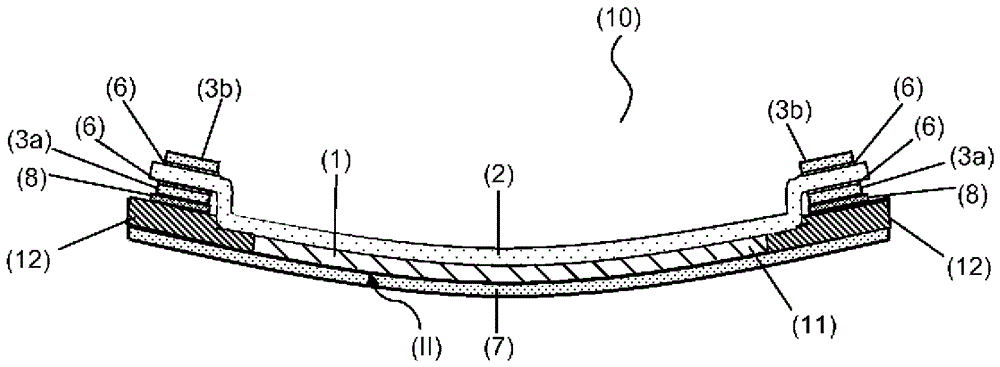

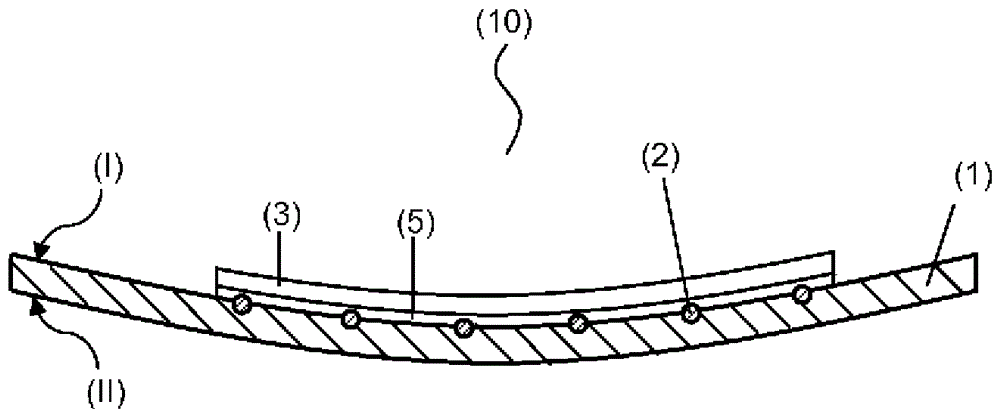

[0059] figure 1 , image 3 and Figure 4 Correspondingly, details of a lamp cover 10 according to the invention for a passenger vehicle headlight are shown. The polymer matrix 1 contains polycarbonate (PC) and has a thickness of 4 mm. Six heating wires are arranged as lines 2 with a length of 20 cm on the inner side (I) of the polymer matrix 1 . The lines 2 are arranged parallel to each other and horizontally. Line 2 contains copper and has a thickness of 70 μm. The distance between two adjacent heating wires is 10mm. The lines 2 are embedded in the polymer matrix over their entire length by means of ultrasound, the penetration depth being approximately 45 μm.

[0060] Each line 2 is electrically connected to two bus bars 3 . The electrical connection between the lines 2 and the busbars 3 is achieved via an electrically conductive adhesive 5 . The bus bar 3 contains copper and has a thickness of 50 μm, a length of 6 cm and a width of 1 cm.

[0061] The bus bar 3 is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com