Uranium trioxide fluidized bed hydrogen reduction process

A uranium trioxide and fluidized bed technology, applied in the field of uranium trioxide fluidized bed hydrogen reduction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

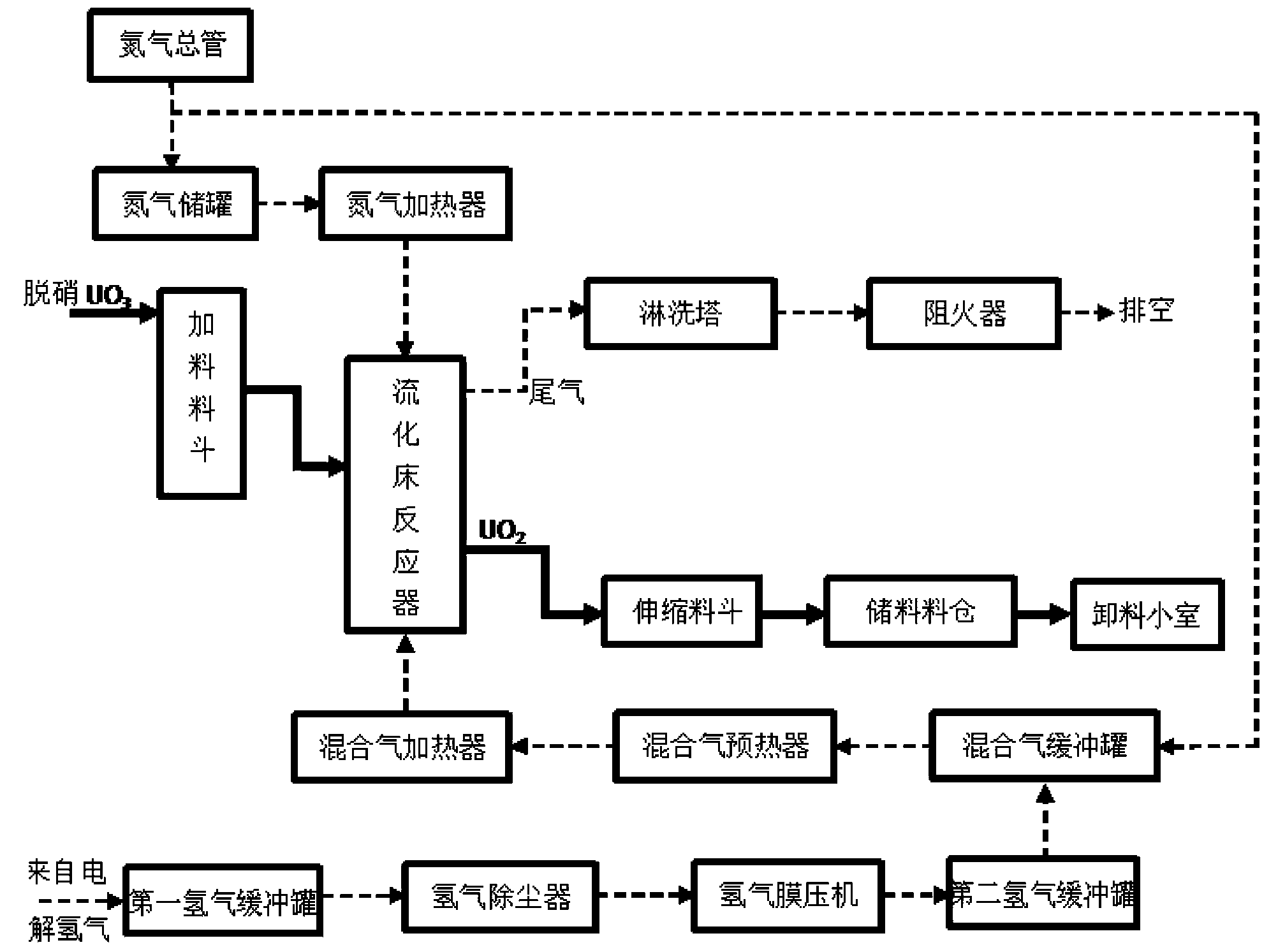

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0025] According to the above process flow, establish a 100kgU / h process system and carry out an engineering test system.

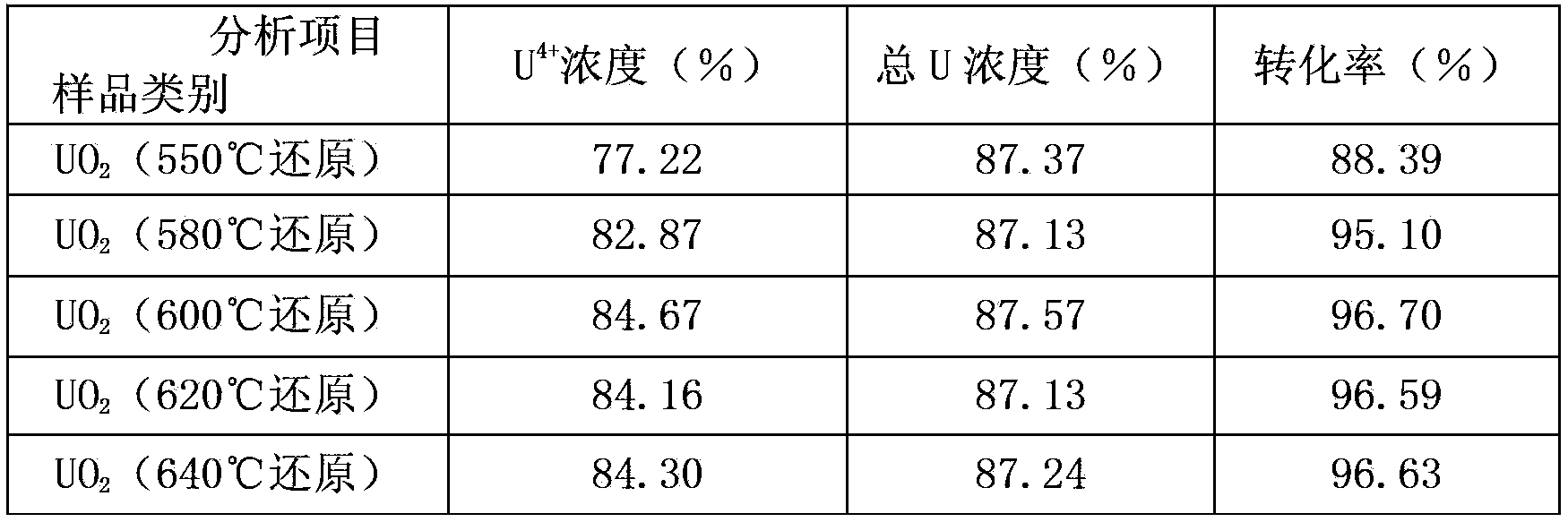

[0026] At the temperatures of 550±10°C, 580±10°C, 600±10°C, 620±10°C, 640±10°C, the hydrogen excess is about 100% (based on 100kgU per hour), and the molar ratio of nitrogen to hydrogen is 1:3, and the reaction time was 8h, and the reduction reaction was carried out. The analysis results of product UO2 are shown in Table 1. From the data in Table 1, it can be known that as the temperature increases, the reduction conversion rate also increases. When it reaches 600±10°C, the reduction conversion rate of UO3 basically no longer increases, so the optimal reaction temperature is 600±10°C.

[0027] Table 1UO 3 The relationship between reduction conversion rate and temperature

[0028]

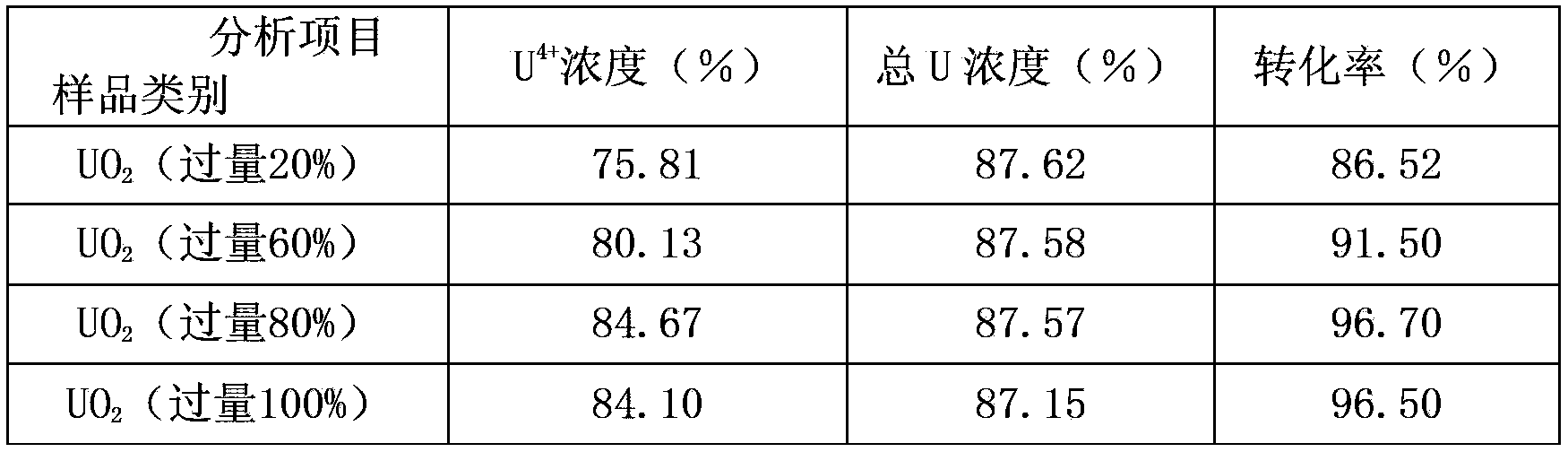

[0029] The reduction reaction was carried o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com