Method for treating p-nitrobenzoic acid wastewater with activated carbon through catalytic reduction

A technology of p-nitrobenzoic acid and activated carbon, applied in the direction of reduced water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., to achieve low requirements for reaction equipment, cost saving, and simple and easy methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: Sodium thiosulfate reduces p-nitrobenzoic acid wastewater

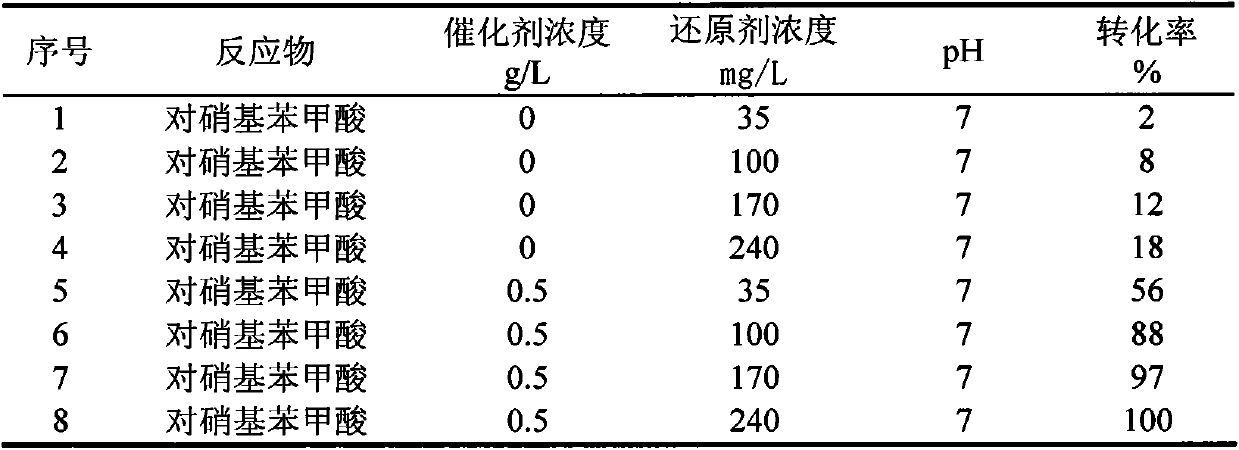

[0024] In 8 1L anaerobic simulated reactors, adding pH is 7 phosphate buffer solution and concentration is the p-nitrobenzoic acid waste water of 30mg / L, is filled with high-purity nitrogen (to remove the nitrogen in the reaction system) in the reactor. Oxygen, form anaerobic environment), add 35mg / L, 100mg / L, 170mg / L, 240mg / L reducing agent sodium thiosulfate solution respectively in the reactor, then, do not add catalyst in No. 1-4 reactor, In No. 5-8 reactor, add 0.5g gac respectively (make its concentration be 0.5g / L) as reaction catalyst. The reactor is sealed and placed in a rotary oscillator, and the reaction is shaken at a speed of 150-200 rpm at normal temperature and pressure for 48 hours. After the reaction, the reduced product is p-aminobenzoic acid. The conversion rate of p-nitrobenzoic acid is shown in Table 1.

[0025] Table 1 Conversion rate of p-nitrobenzoic acid under sodium th...

Embodiment 2

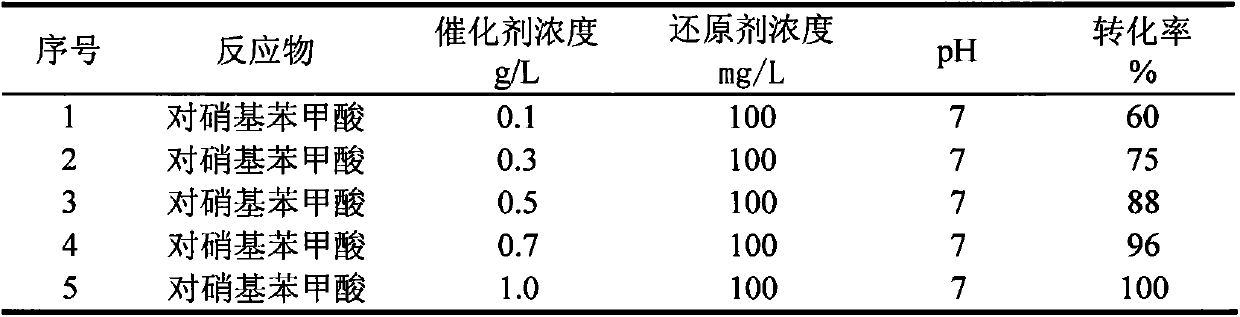

[0027] Embodiment 2: Reductive conversion of p-nitrobenzoic acid under different catalyst concentration conditions

[0028] Different from Example 1, in 5 reactors, add respectively the reducing agent sodium thiosulfate solution of 100mg / L, then, add a certain amount of activated carbon (making its concentration be 0.1,0.3,0.5, 0.7, 1.0g / L) as the reaction catalyst. The reactor was sealed and placed in a rotary shaker, and the reaction was shaken at a speed of 150-200 rpm at normal temperature and pressure for 48 hours. The conversion rate of p-nitrobenzoic acid is shown in Table 2.

[0029] Table 2 Reductive transformation of p-nitrobenzoic acid under different catalyst concentrations

[0030]

Embodiment 3

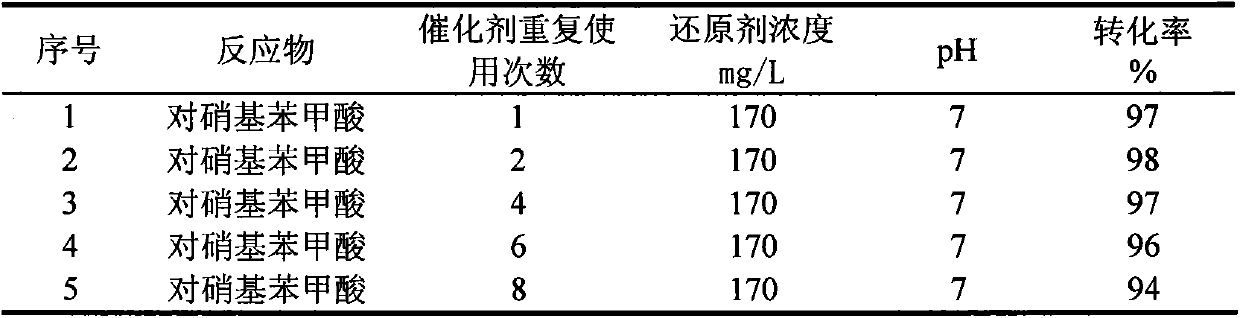

[0031] Embodiment 3: the reductive transformation of p-nitrobenzoic acid when catalyst is reused

[0032] Different from Example 1, in 5 reactors, add respectively the reducing agent sodium thiosulfate solution of 170mg / L; 4, 6, 8 times) as a reaction catalyst. The reactor was sealed and placed in a rotary shaker, and the reaction was shaken at a speed of 150-200 rpm at normal temperature and pressure for 48 hours. The conversion rate of p-nitrobenzoic acid is shown in Table 3.

[0033] Table 3 Reductive transformation of p-nitrobenzoic acid under different catalyst concentrations

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com