Preparation method, product and application of a pH-responsive nano-silver assembly

A nano-silver and assembly technology, which is applied in the field of preparation of pH-responsive nano-silver assemblies, can solve the problems of increasing the dosage of drugs, difficult to kill biofilm bacteria and drug-resistant bacteria, and achieves inhibiting and destroying bacterial biofilms. , good clinical transformation possibility, the effect of accelerating surface corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: Preparation of silver nanoparticles

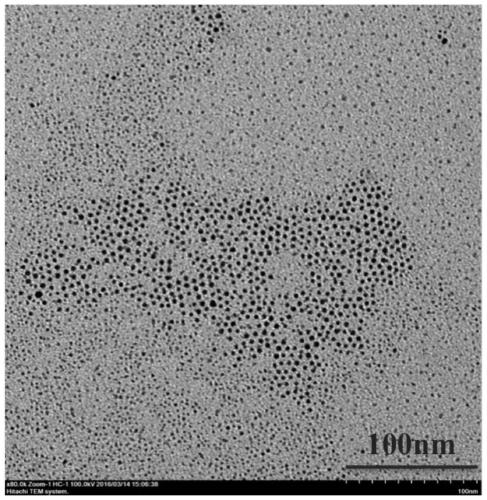

[0034] Mix 170 mg of silver nitrate with 0.5 mL of oleylamine and 4.5 mL of oleic acid, stir at 70 °C for 1.5 hours under vacuum, heat the mixture to 180 °C at a rate of 1 °C / min, and keep the temperature when the system temperature reaches 180 °C temperature for 2 minutes, rapid cooling, adding a mixed solution of methanol and ethanol for precipitation, and centrifuging to obtain silver nanoparticles. The morphology of silver nanoparticles was characterized by transmission electron microscopy, and the results were as follows: figure 1 As shown, the particle size is about 3-5 nm.

Embodiment 2

[0035] Embodiment 2: Preparation of silver nanoparticles

[0036] Mix 170 mg of silver nitrate with 1 mL of oleylamine and 5 mL of oleic acid, stir at 70 °C for 2 hours under vacuum, heat the mixture to 180 °C at a speed of 10 °C / min, and cool it rapidly when the system temperature reaches 180 °C. A mixed solution of methanol and ethanol is added for precipitation, and centrifuged to obtain silver nanoparticles, and the size of the obtained silver nanoparticles is 6-8nm.

Embodiment 3

[0037] Embodiment 3: Preparation of polyethylene glycol-poly(aspartic acid-imidazole)-polyalanine

[0038] Dissolve 0.6g of polyethylene glycol-polyaspartate-polyalanine in 5mL of N,N-dimethylformamide, add 1mL of 1-(3-aminopropyl)imidazole, and Reaction at room temperature for 12h. Subsequently, the reaction solution was added to 25 mL of 0.1N dilute hydrochloric acid, and transferred to a dialysis bag (molecular weight cut-off: 3500), and dialyzed with 0.01N dilute hydrochloric acid as the dialysis medium. Finally, freeze-dry to obtain polyethylene glycol-poly(aspartic acid-imidazole)-polyalanine solid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com