A kind of slag additive and its preparation method and application

An additive and slag technology, which is applied in the field of slag additives and its preparation, can solve the problems of early strength decline, can not meet requirements well, can not achieve mechanical performance indicators, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

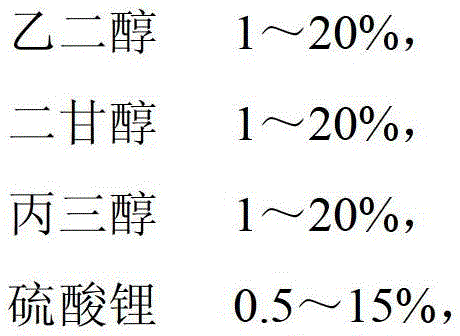

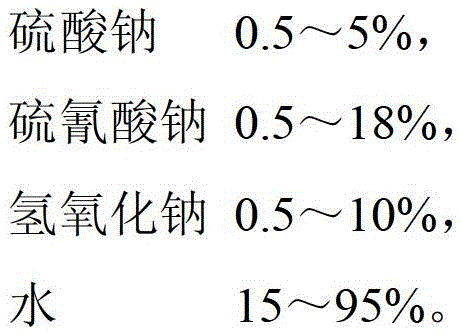

[0031] Weigh the raw materials of each component according to the following ratio: ethylene glycol: 17%, diethylene glycol: 14%, glycerol: 12%, lithium sulfate 12%, sodium sulfate: 2%, sodium thiocyanate: 15% , Sodium hydroxide: 5%, water 23%; mix and stir evenly to obtain the slag activation enhancer.

[0032] The amount of the slag additive prepared in this example used as a slag activation enhancer is 0.1% of the slag mass.

Embodiment 2

[0034] Weigh the raw materials of each component according to the following proportions: ethylene glycol: 8%, diethylene glycol: 2%, glycerol: 2%, lithium sulfate 6%, sodium sulfate: 3%, sodium thiocyanate: 10% , Sodium hydroxide: 3%, water 66%; mix and stir evenly to obtain the slag activation enhancer.

[0035] The amount of the slag additive prepared in this example used as a slag activation enhancer is 0.3% of the slag mass.

Embodiment 3

[0037] Weigh the raw materials of each component according to the following ratio: ethylene glycol: 3%, diethylene glycol: 7%, glycerol: 6%, lithium sulfate 2%, sodium sulfate: 5%, sodium thiocyanate: 4% , Sodium hydroxide: 2%, water 71%; mix and stir evenly to obtain the slag activation enhancer.

[0038] The amount of the slag additive prepared in this example used as a slag activation enhancer is 0.5% of the slag mass.

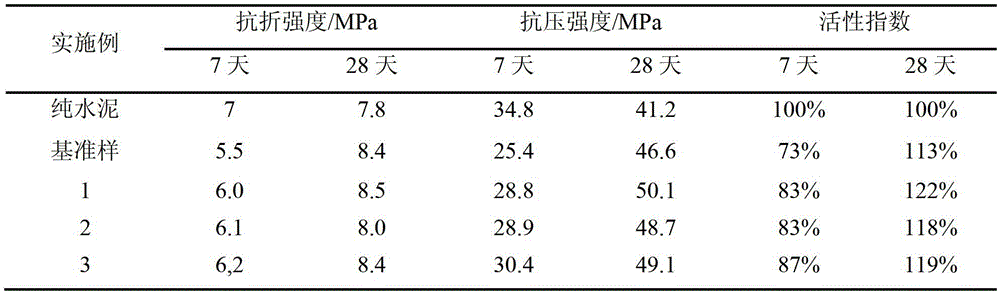

[0039] Using the slag activated enhancer prepared in the above three examples, the cement mortar test was carried out according to the requirements of GB / T17671-1999. Calculated according to GB / T18046-2008, the activity index of slag. The obtained mortar strength and activity index results are shown in the following table:

[0040]

[0041] Table 1 shows that: using the special activation enhancer of the present invention, the 7-day activity index of slag is increased by 10-14%, and the 28-day activity index is increased by 5-9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com