Belt type compact coal mine paste filling device

A paste filling and compact technology, which is applied in the direction of fillings, safety devices, mining equipment, etc., can solve the problems of loose structure, large floor area, unfavorable construction and other problems of the coal mine paste filling system, so as to improve the mixing efficiency and mixing The effect of quality, small footprint, and reduced operating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

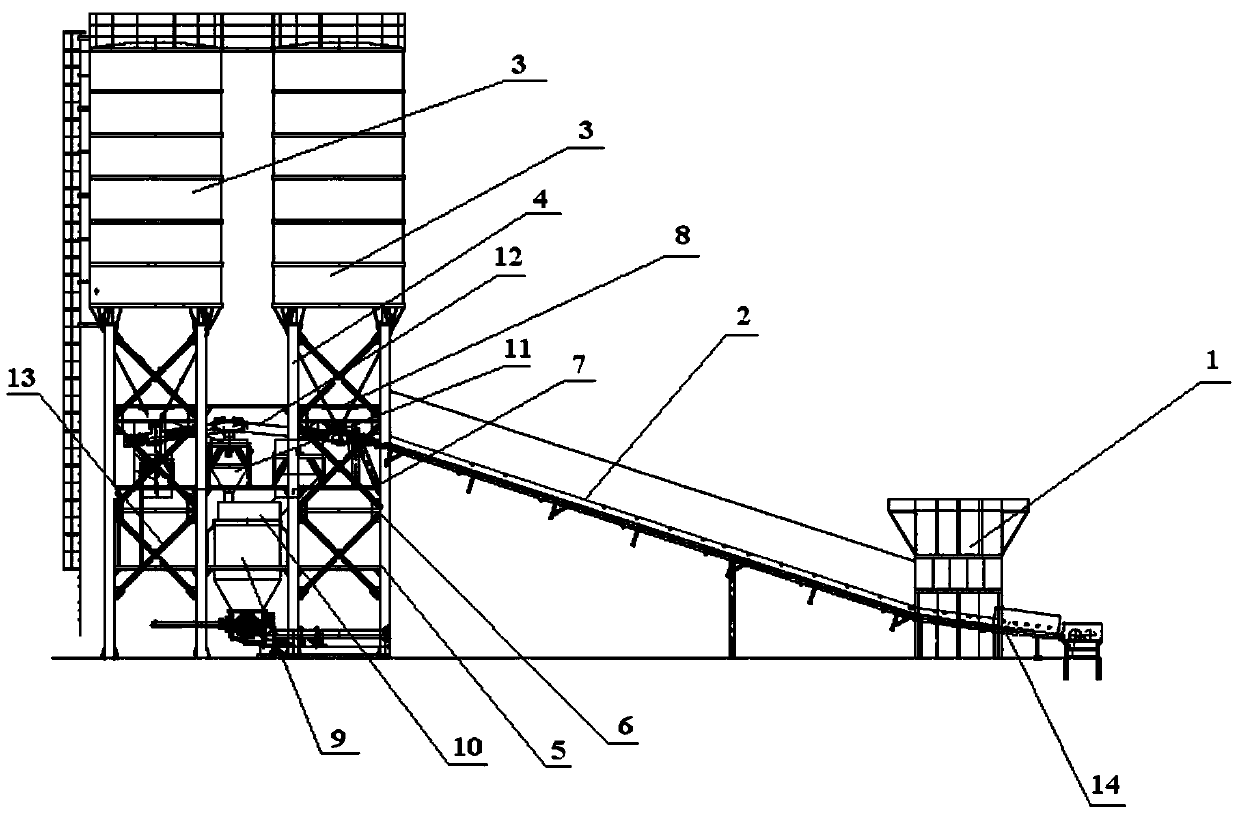

[0036] The belt-type compact coal mine paste filling device described in this embodiment is as follows: figure 1 shown, including:

[0037] Main material storage device 1, the main material storage device is a gangue storage bin;

[0038] The weighing device 14 is arranged below the main material storage device, and is suitable for accepting the blanking of the main material storage device;

[0039] A belt conveyor is connected with the weighing device 14;

[0040] Steel frame 4, the steel frame 4 is fixed on the ground through a concrete base, the steel frame 4 is composed of a plurality of steel legs, and the adjacent steel legs are provided with a cross fixed to the steel frame The steel bracket 13 on the legs, in addition, the first floor 5, the second floor 6, the third floor 7 and the fourth floor 8 are also arranged in the steel frame, the first floor 5, the second The floor 6, the third floor 7 and the fourth floor 8 are horizontally fixed on the steel legs, and arran...

Embodiment 2

[0046] The belt-type compact coal mine paste filling device described in this embodiment is as follows: figure 1 shown, including:

[0047] Main material storage device 1, the main material storage device is a gangue storage bin;

[0048] The weighing device 14 is arranged below the main material storage device, and is suitable for accepting the blanking of the main material storage device;

[0049] A belt conveyor is connected with the weighing device 14;

[0050] Steel frame 4, the steel frame 4 is fixed on the ground through a concrete base, the steel frame 4 is composed of a plurality of steel legs, and the adjacent steel legs are provided with a cross fixed to the steel frame The steel bracket 13 on the legs, in addition, the first floor 5, the second floor 6, the third floor 7 and the fourth floor 8 are also arranged in the steel frame, the first floor 5, the second The floor 6, the third floor 7 and the fourth floor 8 are horizontally fixed on the steel legs, and arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com