Filtering method for tracking magnetic control pendular submerged arc welding seam

A submerged arc welding and filter technology, which is applied in the field of welding automatic tracking, can solve the problems of low precision, rough filter filtering, and ineffective filtering, etc., and achieve the effect of improving filtering efficiency and stabilizing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

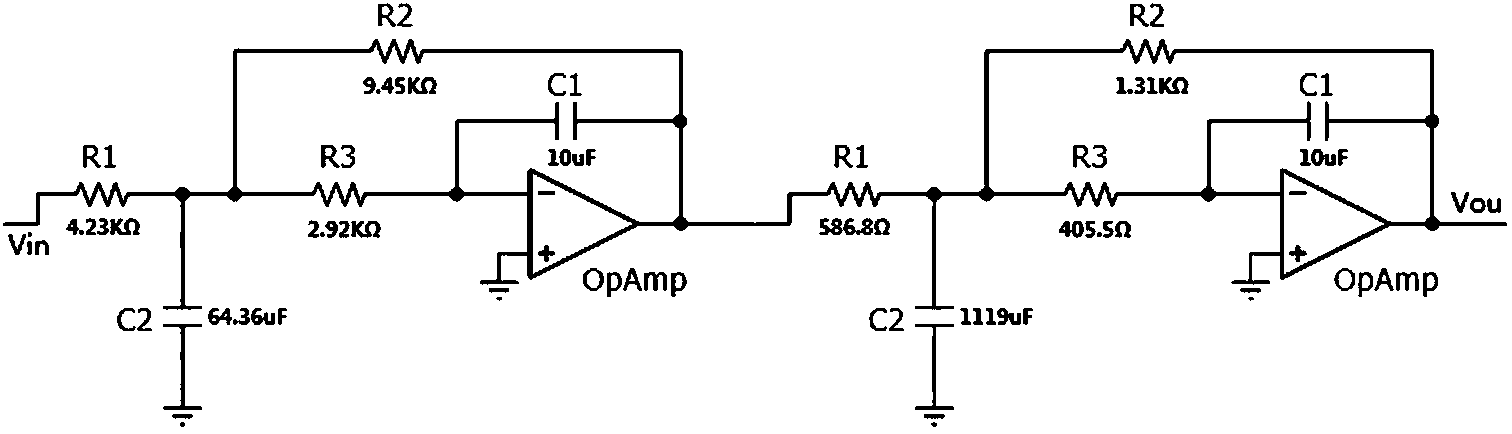

[0012] Embodiment 1, the present invention provides a filtering method for seam tracking of magnetron oscillating submerged arc welding, including a passive filter and two multiple feedback Chebyshev active filter joint filters to perform effective filtering sequentially During welding, the clutter collected by the Hall sensor is filtered by the filter, and the obtained waveform A / D is converted into a digital quantity, and the digital quantity transmitted to the microcontroller is accumulated and averaged for multiple judgments; among them, the passive Filter combined with two multiple feedback Chebyshev active filters is composed of an RC passive filter part with two principles Figure 1 The same, but with different parameters of the original multiple feedback Chebyshev active filter, they will complete the high broadband to low narrow frequency filtering. The waveform VIN1 is stabilized by R1, and the high-frequency part is filtered by capacitor C2 to achieve the effect of ...

Embodiment 2

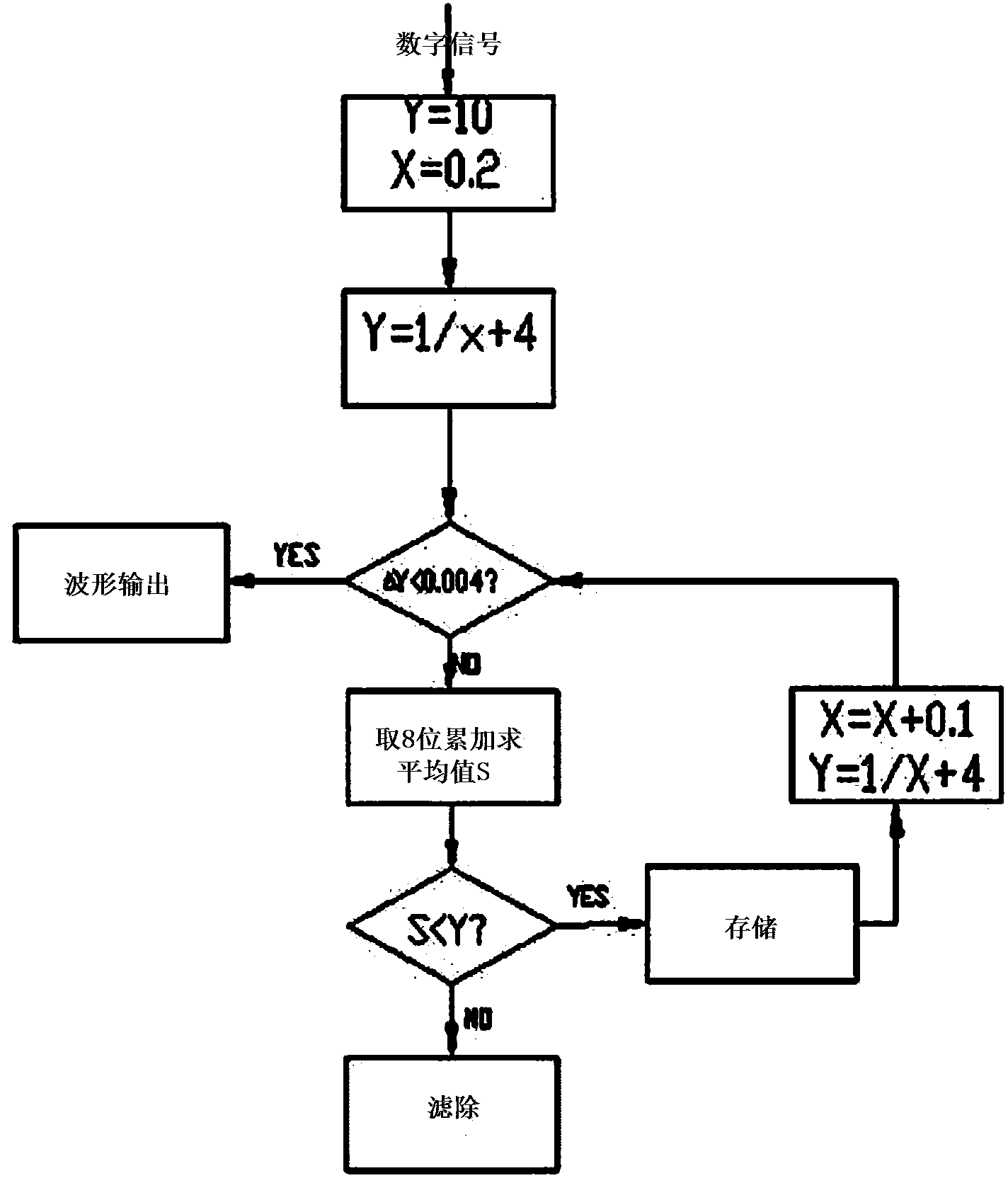

[0014] Embodiment 2, the present invention can also increase the fourth software filtering part, that is, the microcomputer takes 8 data for each operation, calculates the average number after the accumulation, and if it is an ideal state, it will output a section between 0HZ and 4HZ The data. The specific process is as follows: first assign initial values to Y and X, and then perform judgment function calculations, judge △Y and compare it with the set precision (0.004), and output the waveform if it meets the precision requirements, otherwise continue to take 8 to calculate the average value, and judge The size of the average value S and Y, if S is greater than Y, it will be filtered out, if it is less than Y, continue to perform judgment function operations, and then judge the accuracy of △Y, and so on, until the accuracy requirements are met, and the final waveform is output. Due to the first three filtering parts , to improve the filtering efficiency of the fourth part r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com