Preparation method for wall-broken epimedium preparation

A technology of epimedium and preparations, which is applied in the field of preparation of epimedium-broken preparations, can solve the problems of incomplete decoction of active ingredients, easy destruction of heat-sensitive ingredients, and increase of powder specific surface area, so as to improve the utilization rate of active ingredients, Easy disintegration and dispersion, strong stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

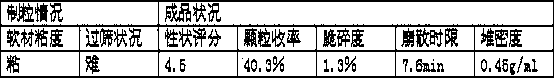

[0037] Take epimedium medicinal material, coarsely pulverize it into a coarse powder of about 100 meshes, and superfinely pulverize it into a powder in which 90% of the particles in the superfine powder have a particle size less than or equal to 45 μm, add ethanol-water solution (the mass fraction of ethanol is 30%) ) soft material by wet method, the ratio of solution to superfine powder is 0.9:1 (by weight), after mixing, pre-installed 10-mesh sieve, the extrusion speed is 50r / min, and the extrusion force is 1MPa to make wet granules. The wet granules were transferred to a hot air circulation oven, set the drying temperature to 85°C, dried for 2.5 hours until dry, and the whole granules were sieved to obtain the epimedium wall-broken preparation.

[0038]

[0039] Note: The full score is 10.

Embodiment 2

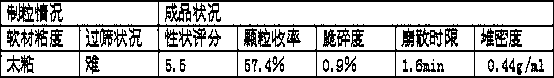

[0041]Take epimedium medicinal material, coarsely pulverize it into a coarse powder of about 100 meshes, and superfinely pulverize it into a powder in which 90% of the particles in the superfine powder have a particle size less than or equal to 45 μm, add ethanol-water solution (the mass fraction of ethanol is 65%) ) soft material by wet method, the ratio of solution to superfine powder is 1.4:1 (by weight), after mixing, pre-installed 10-mesh sieve, the extrusion speed is 50r / min, and the extrusion force is 0.8MPa to make wet granules , the wet granules were transposed into a vacuum microwave drying oven, the drying temperature was set at 45°C, and dried for 0.75h until dry.

[0042]

[0043] Note: The full score is 10.

Embodiment 3

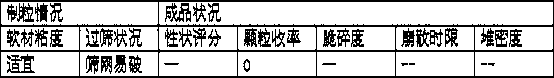

[0045] Take epimedium medicinal material, coarsely pulverize it into a coarse powder of about 100 meshes, and superfinely pulverize it into a powder in which 90% of the particles in the superfine powder have a particle size less than or equal to 45 μm, add ethanol-water solution (the mass fraction of ethanol is 90%) ) soft material by wet method, the ratio of solution to superfine powder is 1.5:1 (by weight), after mixing, pre-installed with a 30-mesh sieve, the extrusion speed is 80r / min, and the extrusion force is 0.3MPa to make wet granules , the wet granules were placed in a hot air circulation oven, the drying temperature was set at 85°C, and dried for 2.5 hours until dry.

[0046]

[0047] Note: The full score is 10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com