Composite fertilizer for improving output of sugarcane, and preparation method of composite fertilizer

A compound fertilizer and yield technology, applied in the directions of urea compound fertilizer, nitrogen fertilizer, magnesium fertilizer, etc., can solve the problems of excessive soil fertility decline, failure to consider specific needs, waste of trace elements, etc., to promote absorption, improve crop quality, and reduce chemical fertilizers. effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The compound fertilizer preparation method that improves sugarcane yield is as follows:

[0035] (1) Pour urea, ammonia water, monoammonium phosphate, calcium silicate, lime, magnesium sulfate, copper sulfate, boric acid, sodium molybdate, zinc sulfate, amino acid and peat into the reaction kettle with heating jacket and stirring device in proportion In the process, the temperature was controlled at 40° C. and stirred for 70 minutes to obtain the primary mixture, wherein the stirring rate was controlled at 300 rad / min.

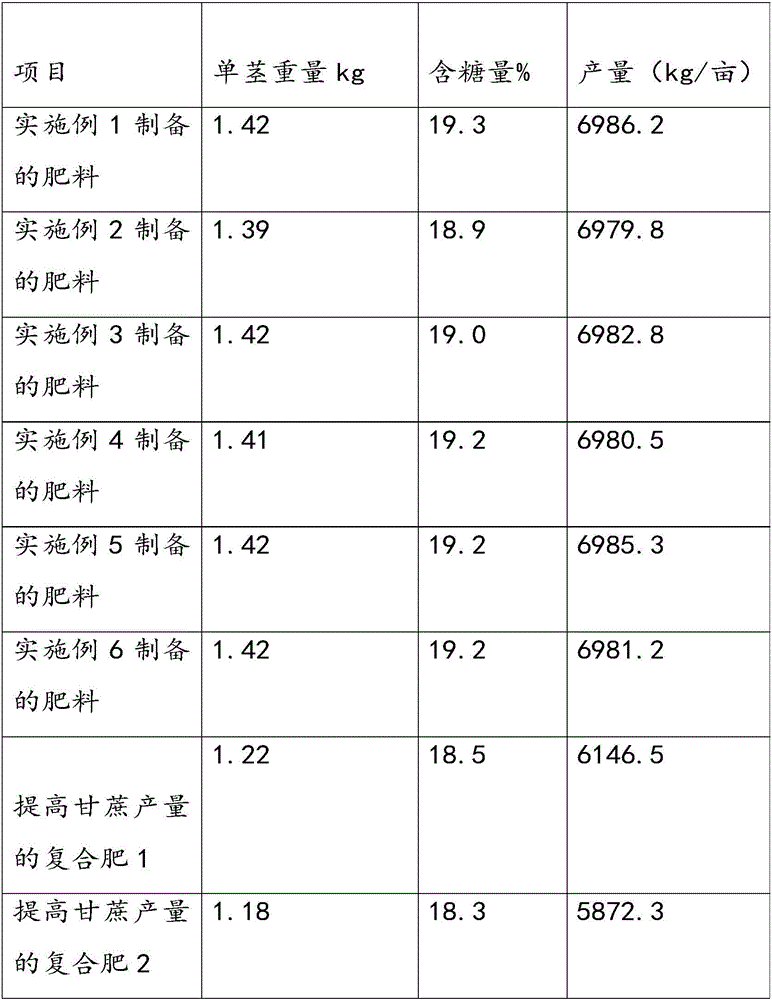

[0036] (2) After testing, each active ingredient is calculated according to the mass percentage of pure nutrients, including: 35% of macroelements, 8% of medium elements, 0.1% of trace elements and 15% of organic auxiliary materials; among them, Si element and Ca element The mass sum is 5%.

[0037] (3) Pour out the initial mixture from the reaction kettle, put it into a granulator for granulation, and dry it at a temperature of 90° C., cool it, pass t...

Embodiment 2

[0039] The compound fertilizer preparation method that improves sugarcane yield is as follows:

[0040] (1) urea, monoammonium phosphate, calcium silicate, lime, magnesium sulfate, copper sulfate, boric acid, sodium molybdate, zinc sulfate containing crystal water, amino acid, humic acid, fulvic acid, peat and zeolite in proportion Pour it into a reaction kettle with a heating jacket and a stirring device, control the temperature at 50°C and stir for 80 minutes to obtain the primary mixture, and the stirring rate is controlled at 200rad / min.

[0041] (2) After testing, each active ingredient is calculated by mass percentage of pure nutrients, including: 40% macroelements, 14% medium elements, 1% trace elements and 13% organic auxiliary materials; among them, Si element and Ca element The mass sum is 10%.

[0042] (3) Pour out the primary mixture from the reaction kettle, put it into a granulator for granulation, dry at 100° C., cool, and pass through a 100-mesh sieve to obtai...

Embodiment 3

[0044] The compound fertilizer preparation method that improves sugarcane yield is as follows:

[0045] (1) Ammonium nitrate, ammonium phosphate, monoammonium phosphate, diammonium phosphate, potassium chloride, potassium sulfate, plant ash, potassium Epsom salt, calcium silicate, sodium silicate, lime, magnesium sulfate, ferrous sulfate, zinc sulfate , copper sulfate, copper ammonium phosphate, borax, ammonium molybdate, sodium molybdate, zinc sulfate and zinc sulfide, amino acids, humic acid, fulvic acid and peat, zeolite are poured into the reaction with heating jacket and stirring device in proportion In the kettle, the temperature was controlled at 45°C and stirred for 75 minutes to obtain the primary mixture, and the stirring rate was controlled at 250rad / min.

[0046] (2) After testing, each active ingredient includes: 28% macroelements, 12% medium elements, 1.2% microelements and 17% organic auxiliary materials according to the mass percentage of pure nutrients; among ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com