Overturn positioner

A technology of positioner and tire rotation, which is applied in metal processing, workbenches, manufacturing tools, etc., can solve the problems of low hydraulic system efficiency, complicated maintenance, and sensitive hydraulic system to dust, and achieve reasonable structural design and low power consumption for turning over Low, running, and shock-free performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

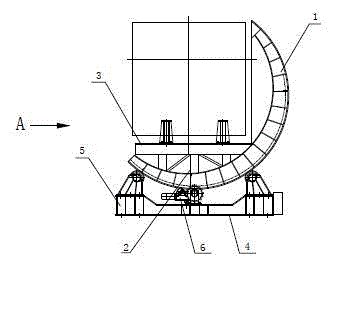

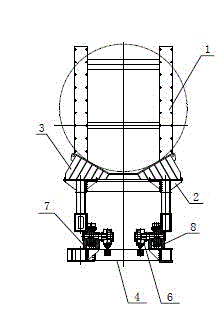

[0015] Such as figure 1 , figure 2 As shown, a new type of turning and shifting machine of the present invention is composed of a C-type rolling cage, a rolling wheel, a turning drive device and a control system. The C-type rolling cage is located above the rolling tires, and the rolling cage consists of two C-shaped box girders 1 are composed of two C-shaped box girders 1, four connecting beams 2 and oblique tension bars are arranged between two C-shaped box girders 1, V-shaped brackets 3 are installed on the table of C-shaped box girder 1, and C-shaped box girders There are several arc-shaped positioning bosses on the inner side of the beam 1; the roller wheel is composed of a base 4 and a driven roller frame 5, and the driven roller frame 5 is installed on the base 4; the turning drive device is located under the C-shaped box beam 1 , and installed on the roller wheel, it is composed of a motor 6, a reducer 7, a transmission gear and its bearing seat 8, and the reducer 7 ...

Embodiment 2

[0017] Such as figure 1 , figure 2 Shown, a kind of novel overturn positioner of the present invention, except that the connecting crossbeam that is provided with between two C-shaped box girders 1 and oblique tie bar are six, all the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com