Method for synthesizing sweet saponin with bitter and fallen grosvenor momordica fruit as raw material

A technology of mangosteen and grosvenor fruit, applied in the field of food chemistry, can solve problems that cannot be solved fundamentally, and achieve the effect of increasing income and solving the problems of bitter fruit and grove fruit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Preparation of Momordica grosvenori bitter saponins:

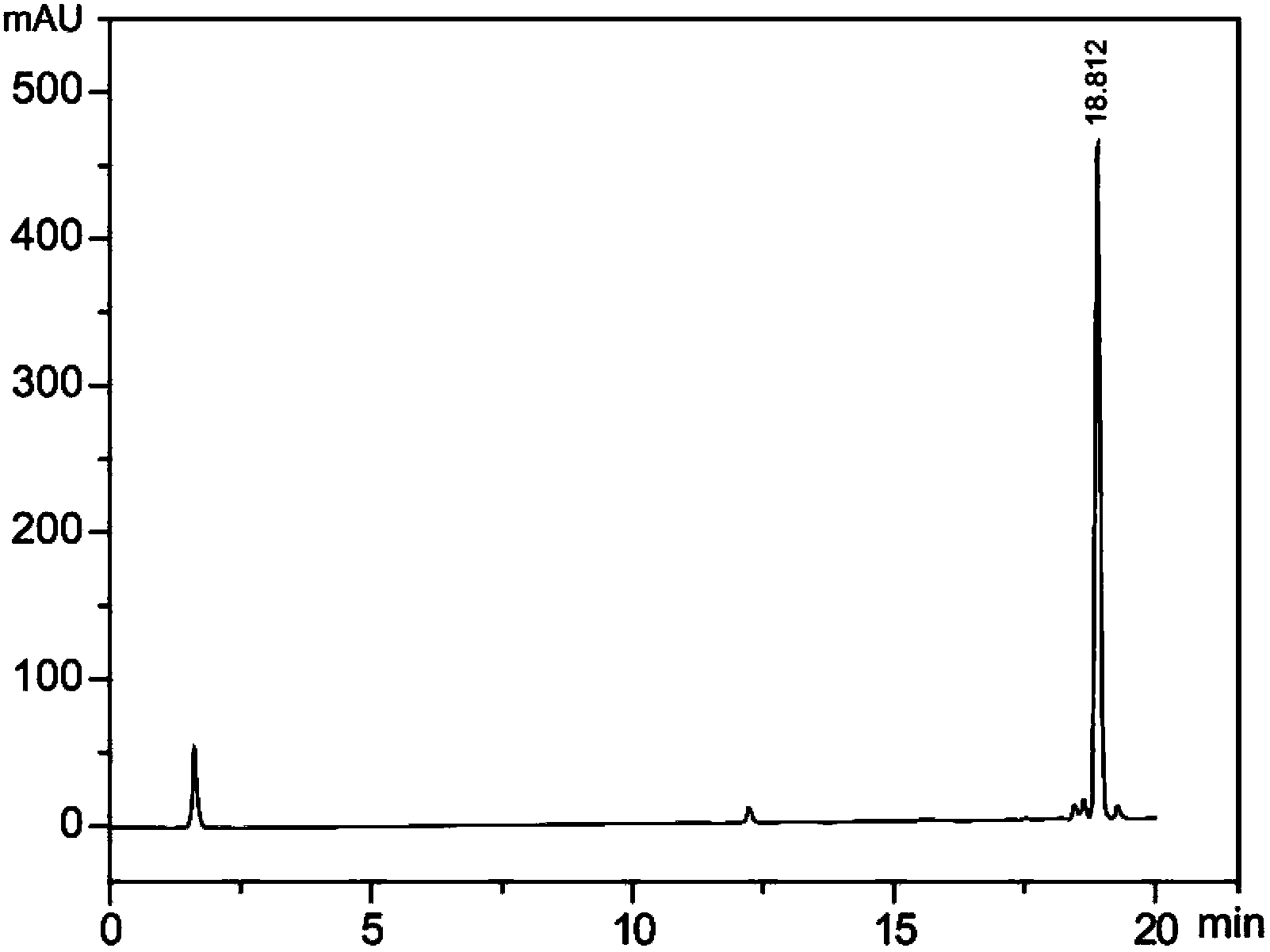

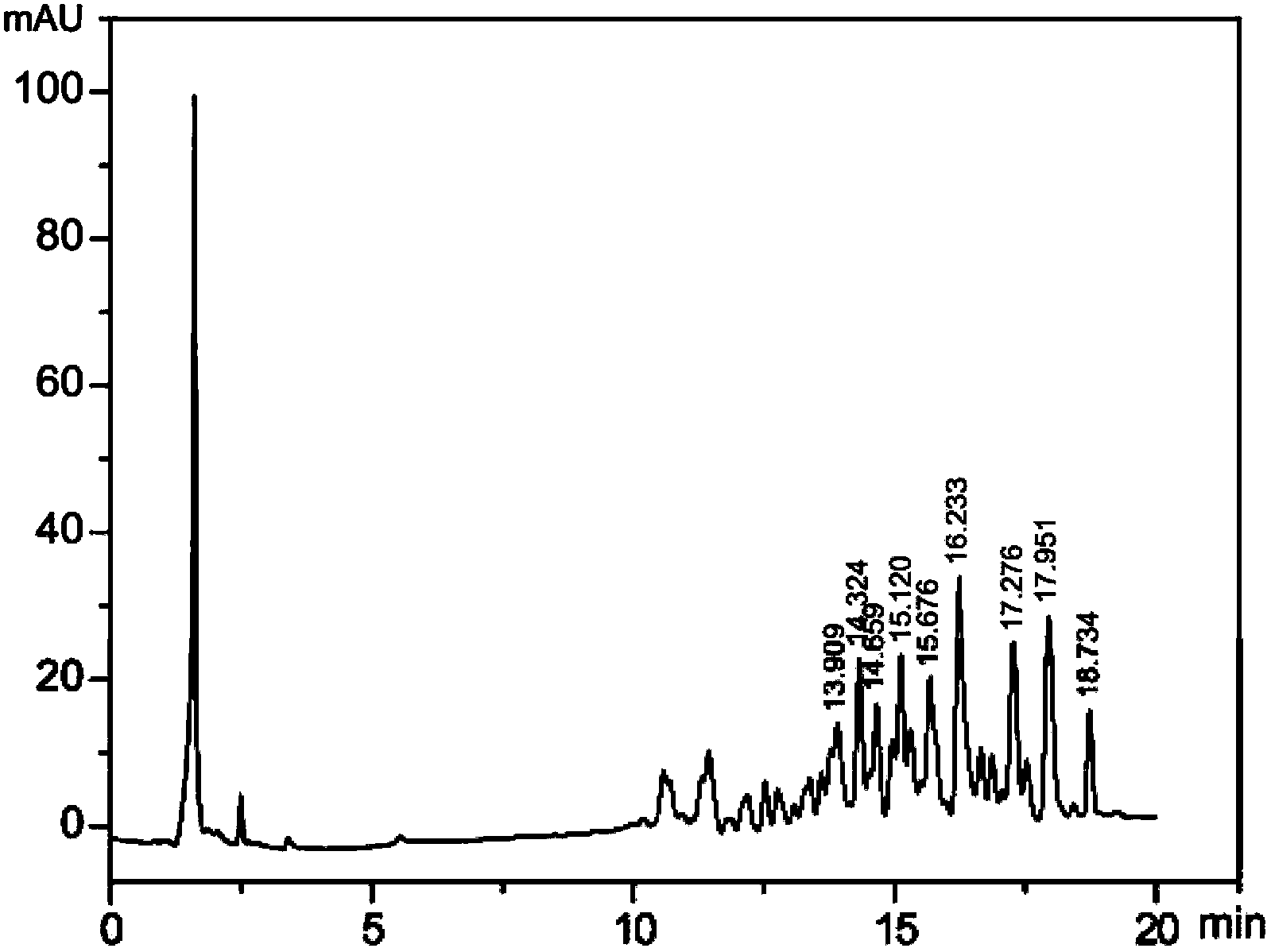

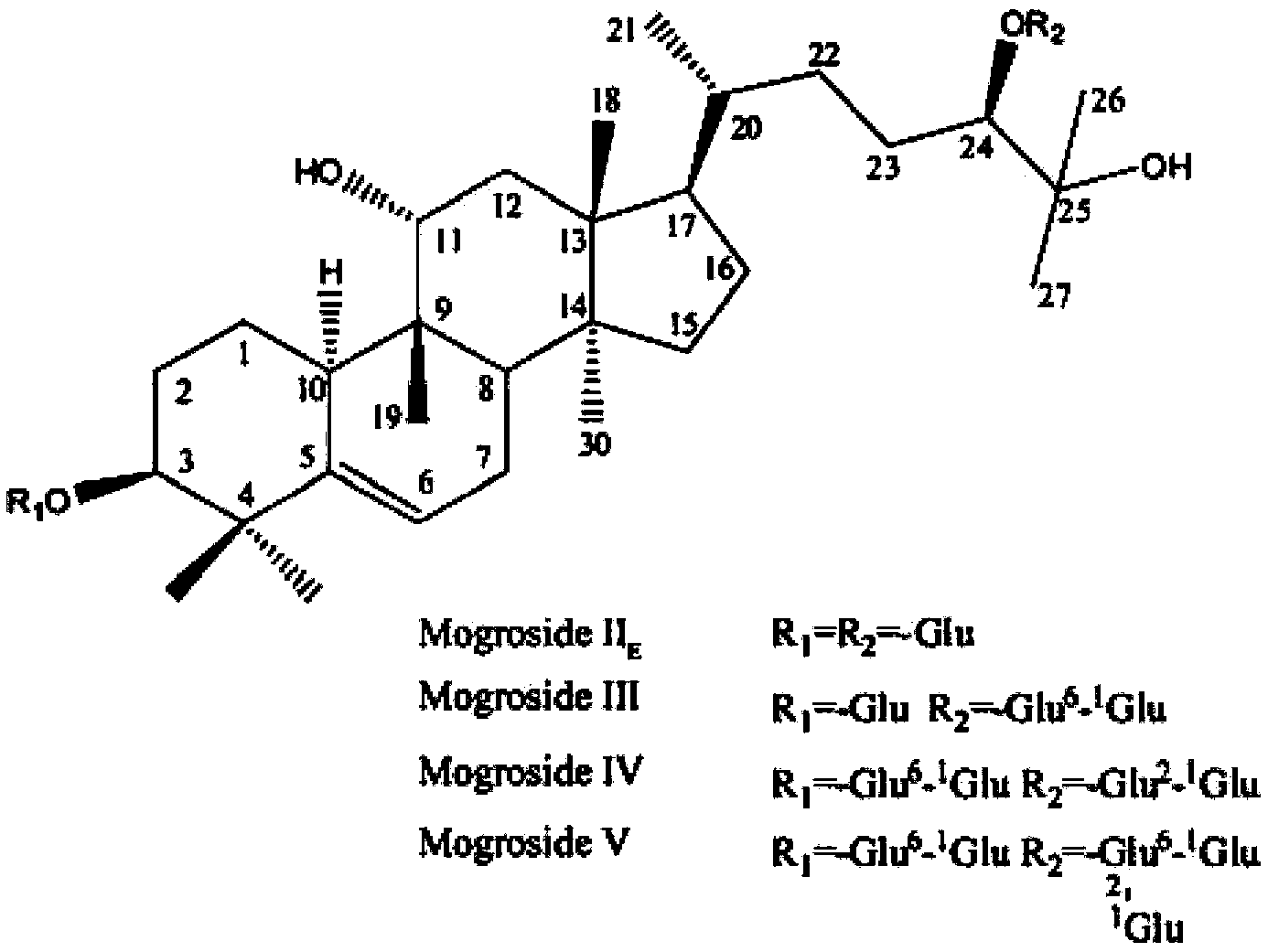

[0027] Take 50 fresh tender fruits (2.3Kg), wash them, crush them, put them in an extraction container, add 7.5L of water to decoct for extraction for 1 hour, filter, add 6L of water to the filter residue and decoct for 1 hour, filter, add 6L of water to the filter residue Decoct and extract for 1 hour, combine the filtrates to obtain an extract; pass the extract through a D101 macroporous resin column, wash the resin column with water until the effluent is colorless, and then elute with 30% ethanol (to remove the sweet saponins of Luo Han Guo in the extract) , until the sweetness of the eluate disappears or becomes bitter and then elutes with 80% ethanol, followed by thin-layer chromatography detection, collects the 80% ethanol eluate, concentrates under reduced pressure, and dries to obtain 70g of Momordica grosvenori bitter saponins. After testing, Wherein the total content of mogroside II and mogroside III is...

Embodiment 2

[0033] 1) Preparation of Momordica grosvenori bitter saponins:

[0034] Take 20Kg of Luo Han Guo ground fruit, wash, crush, put in the extraction tank, add 50% ethanol 1 times the weight of the raw material to extract at room temperature for 12 hours, filter, add 50% ethanol 1 times the weight of the raw material to extract at room temperature for 12 hours, filter , the filter residue was extracted by adding 50% ethanol with 1 times the weight of the raw material at room temperature for 12 hours, and the filtrate was combined to obtain the extract; % ethanol elution (remove the sweet saponins of Luo Han Guo in the extract), then elute with 80% ethanol, track and detect with thin layer chromatography, collect the 80% ethanol eluate, decolorize with strong basic anion exchange resin, and collect the effluent liquid, concentrated under reduced pressure, and dried to obtain 400 g of Momordica grosvenori picricosides. After testing, the total content of mogroside II and mogroside ...

Embodiment 3

[0040] 1) Preparation of Momordica grosvenori bitter saponins:

[0041] Take 100Kg of Luo Han Guo ground fruit, wash, crush, put in the extraction tank, add water 8 times the weight of the raw material to decoct for 3 hours, filter, add water 5 times the weight of the raw material to decoct the residue for 1 hour, combine the filtrates to obtain the extracted liquid; the extract is passed through the AB-8 macroporous resin column, and the resin column is washed with water until the effluent is colorless, and then eluted with 30% ethanol (removing the sweet saponin of Luo Han Guo in the extract), until the sweetness of the eluent disappears Then eluted with 90% ethanol, followed by TLC detection, collected 90% ethanol eluate, concentrated under reduced pressure, and dried to obtain 2.3Kg of mogroside bitter saponins. After testing, the total content of mogroside Ⅱ and mogroside Ⅲ The content is 57% by weight;

[0042] 2) Enzyme-catalyzed reaction:

[0043] Get 82g of Monk Fru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com