Method for adding water in superfine hematite powder sintering process

The technology of hematite powder and sintering machine is applied in the field of superfine hematite powder sintering and adding water, which can solve the problems of affecting the ratio of sintered ore powder and drum strength, deterioration of sintering conditions, and reduction of liquid phase generation, and the like. The effect of meeting the requirements of moisture control, increasing the output of sintered ore and improving the uniformity of particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

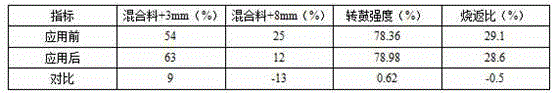

Examples

Embodiment

[0019] A method for adding water to superfine hematite powder sintering, comprising the following contents:

[0020] (1) First, adopt the control method to stabilize the speed of the sintering machine:

[0021] The maximum amount of each adjustment of the speed of the sintering machine is 0.1m / min. Adjust the feeding amount 33 minutes before adjusting the machine speed to stabilize the position of the mixture, reduce the adjustment amount of the batch, and stabilize the moisture content of the mixture;

[0022] (2) Optimize and improve the water addition control method:

[0023] Stop using the method of controlling the amount of water added by the frequency conversion speed regulation of the water pump, install an electromagnetic flow regulating valve on the pipeline of the water supply system, and change the water addition amount controlled by the frequency conversion speed regulation of the water pump to a solenoid valve to control the water addition amount, so as to improve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com