Vacuum synthesis method of lithium-aluminum alloy

A technology of lithium aluminum alloy and synthesis method, which is applied in the direction of electrical components, circuits, battery electrodes, etc., can solve problems such as low primary yield, low primary yield, and difficulties, and achieve improved production efficiency, reduced alloying time, and reduced The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

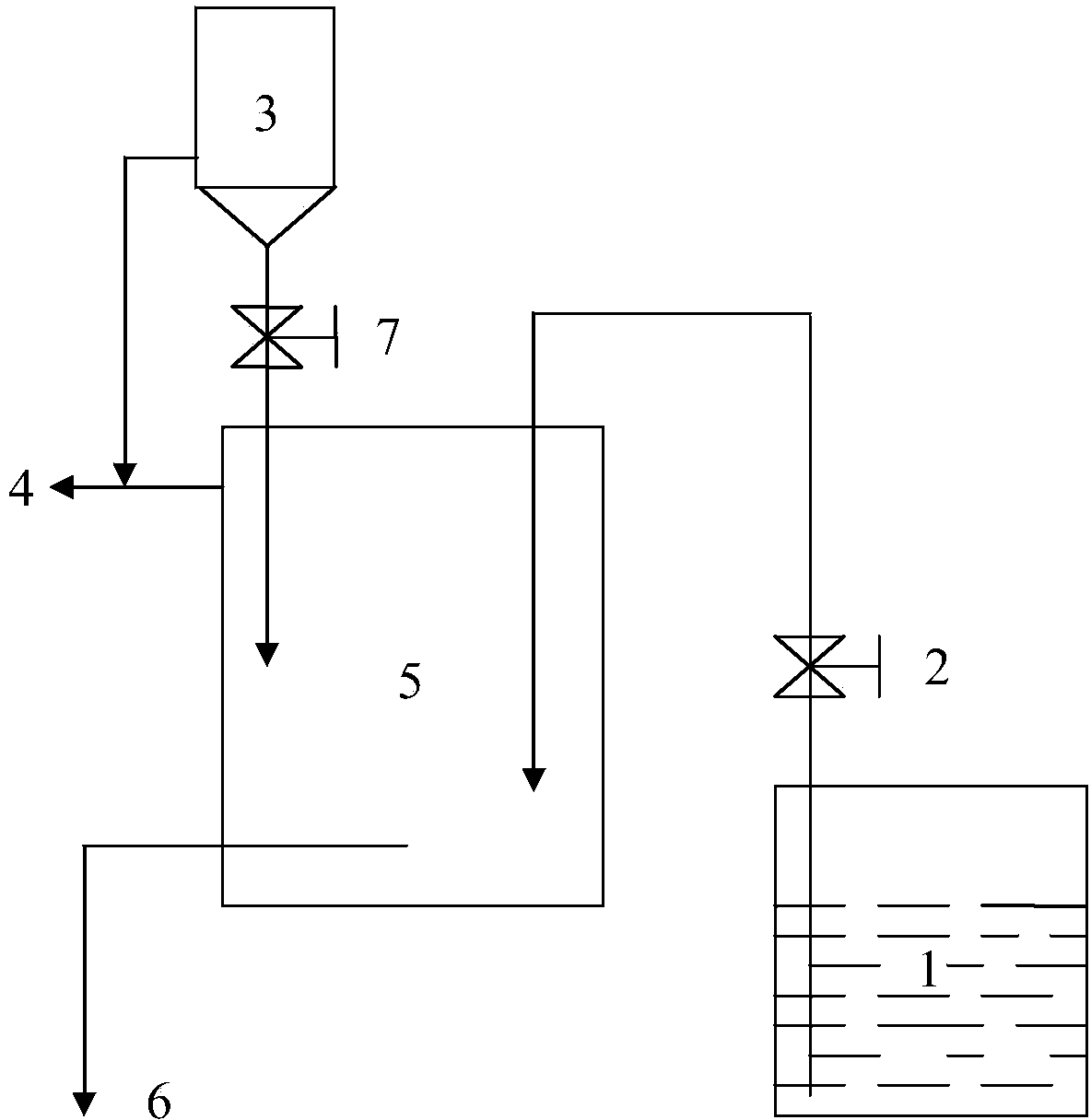

[0023] The vacuum synthesis method of lithium aluminum alloy of the present invention comprises the following steps: mixing aluminum and molten metal lithium in a vacuum environment at a weight ratio of 1:24 to 999, then melting at 190 to 250°C and cooling to obtain lithium aluminum alloy.

[0024] Among them, aluminum can be single-state metal aluminum such as aluminum block, aluminum sheet, aluminum skin, aluminum wire, etc., and its aluminum content is required to be no less than 99wt%, or it can be an aluminum-lithium alloy block with a relatively high aluminum content, of which aluminum The content is 4-99wt%.

[0025] Further, in order to reduce the nitrogen content of the product, simplify production, and reduce costs, the vacuum environment has a vacuum degree of ≤0.1Pa.

[0026] Further, the above-mentioned method of melting metal lithium is to be melted by means of electricity or thermal oil heating under the atmosphere of a drying room with a dew point lower than -...

Embodiment 1

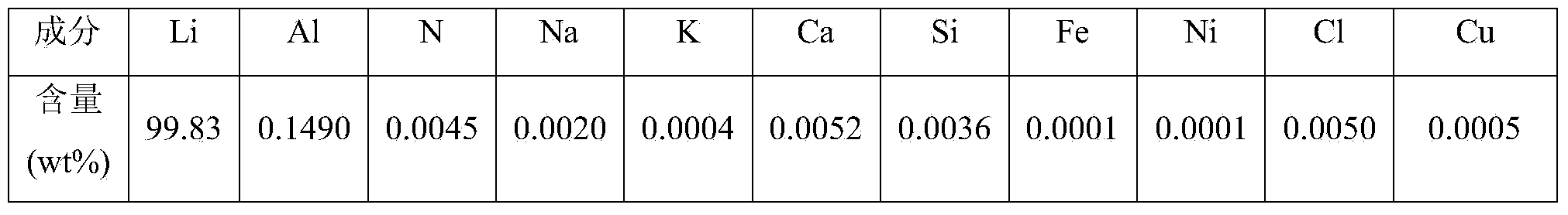

[0035] Under the atmosphere of a drying room with a dew point of -35°C, metal lithium is melted by electric heating, the heating rate is controlled at 200°C / h, and the temperature after melting is controlled at 210°C for use; The vacuum degree is stably lowered below 0.1 Pa, and the above-mentioned molten metal lithium is added to the reaction kettle, and at the same time, aluminum with an aluminum content of 99.5wt% is added, wherein the weight ratio of lithium to aluminum is 665.7:1, and then the reaction kettle The temperature of the alloy liquid is controlled at 220°C, and the melting time is 30 minutes. After the alloying is completed, it is lowered to 200°C and cast. After the casting is completed and the temperature of the alloy ingot reaches the ambient temperature, the mold is opened for demoulding and sampling. The samples taken out are quickly packaged, weighed and recorded. The composition of the obtained lithium aluminum alloy is shown in Table 1.

[0036] Tabl...

Embodiment 2

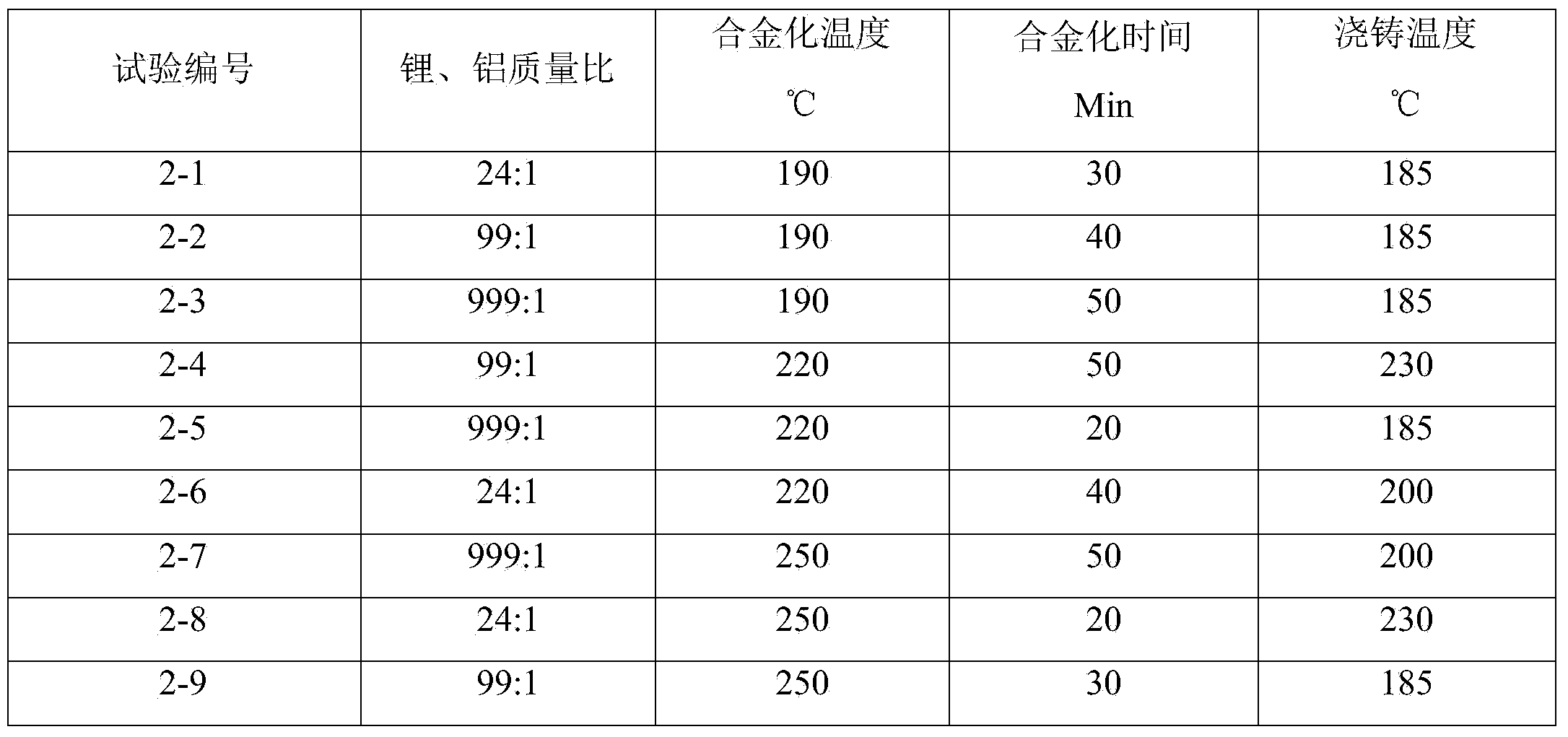

[0039] Under the atmosphere of a drying room with a dew point of -35°C, metal lithium is melted by electric heating, the heating rate is controlled at 200°C / h, and the temperature after melting is controlled at 210°C for use; The vacuum degree is stably lowered to below 0.1 Pa, and the above-mentioned molten metal lithium is added to the reaction kettle, and aluminum is added at the same time, wherein, the temperature of the alloy liquid in the reaction kettle is controlled at 190-250°C, and the melting time is 20-50min. After the alloying is completed, lower the temperature to 185-230°C and perform casting. After the casting is completed and the temperature of the alloy ingot reaches the ambient temperature, the tank is opened for demoulding and sampling. The samples taken out are quickly packaged, weighed and recorded. Wherein, the weight ratio of lithium to aluminum and various parameters are shown in Table 2, and the composition of the obtained lithium aluminum alloy is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com