Power calibration test system and power calibration measurement method

A power calibration and test system technology, applied in the field of measurement, can solve the problems of universality, consistency of effectiveness, and poor accuracy of the power calibration test system in the millimeter wave band, and achieve the effect of improving the generality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

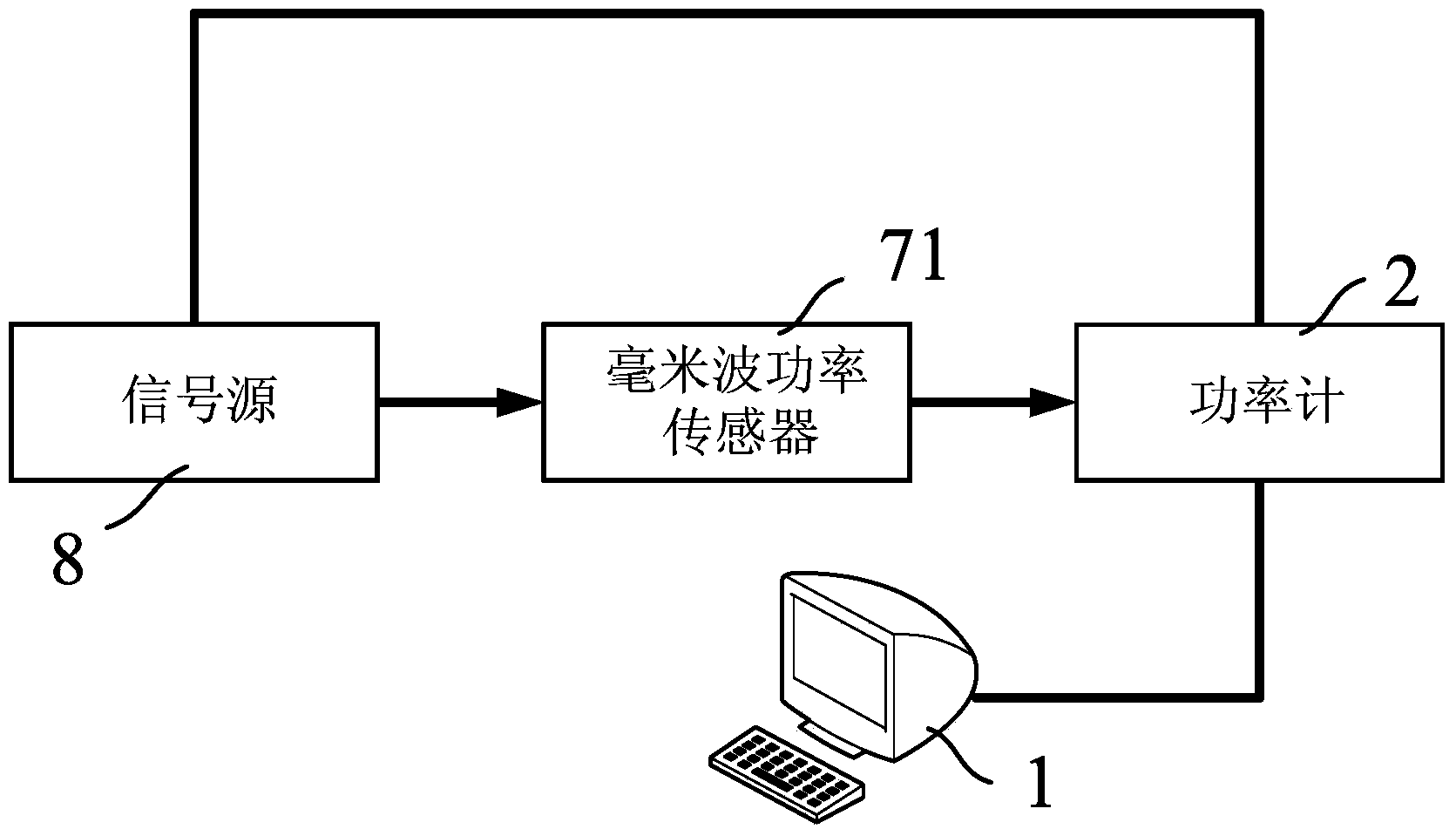

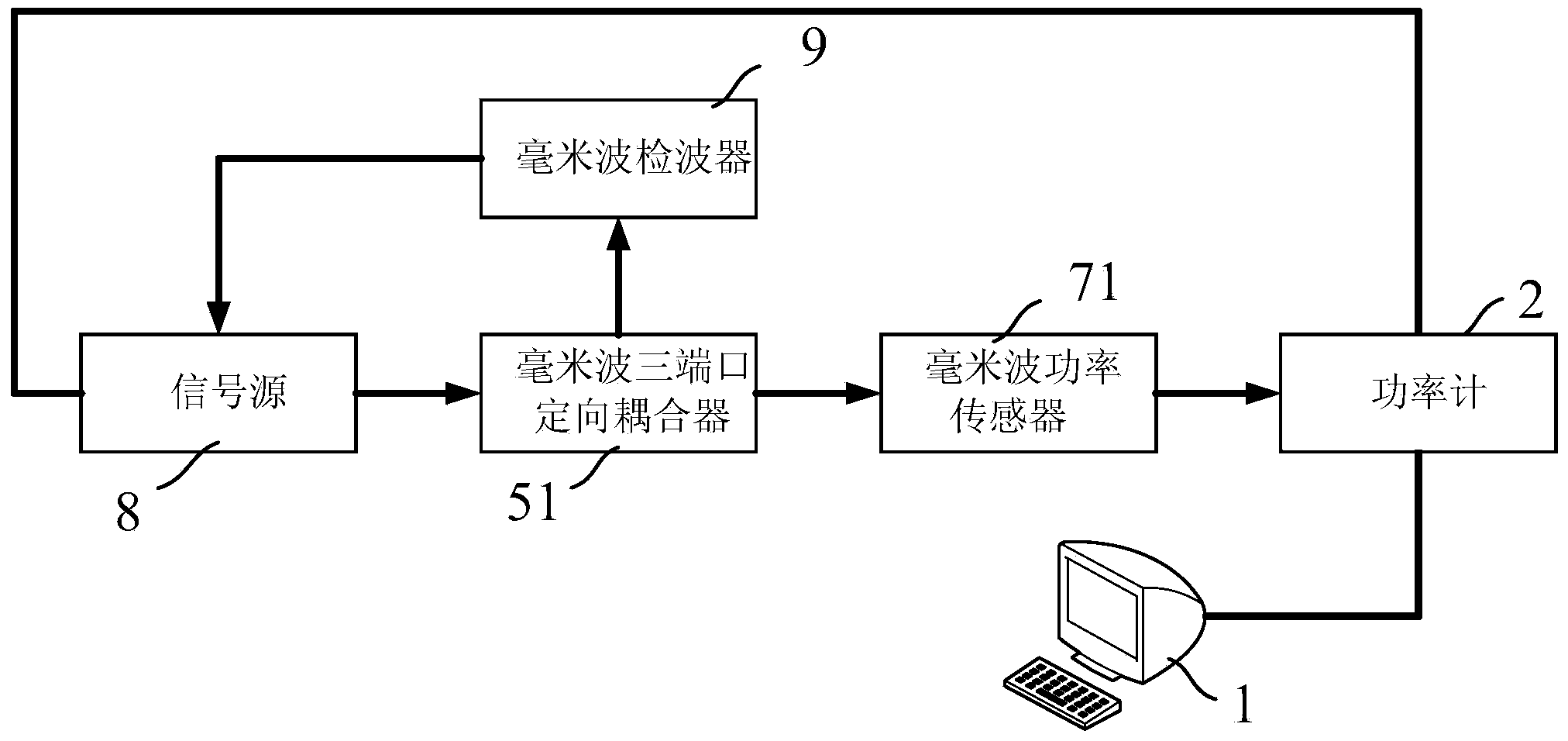

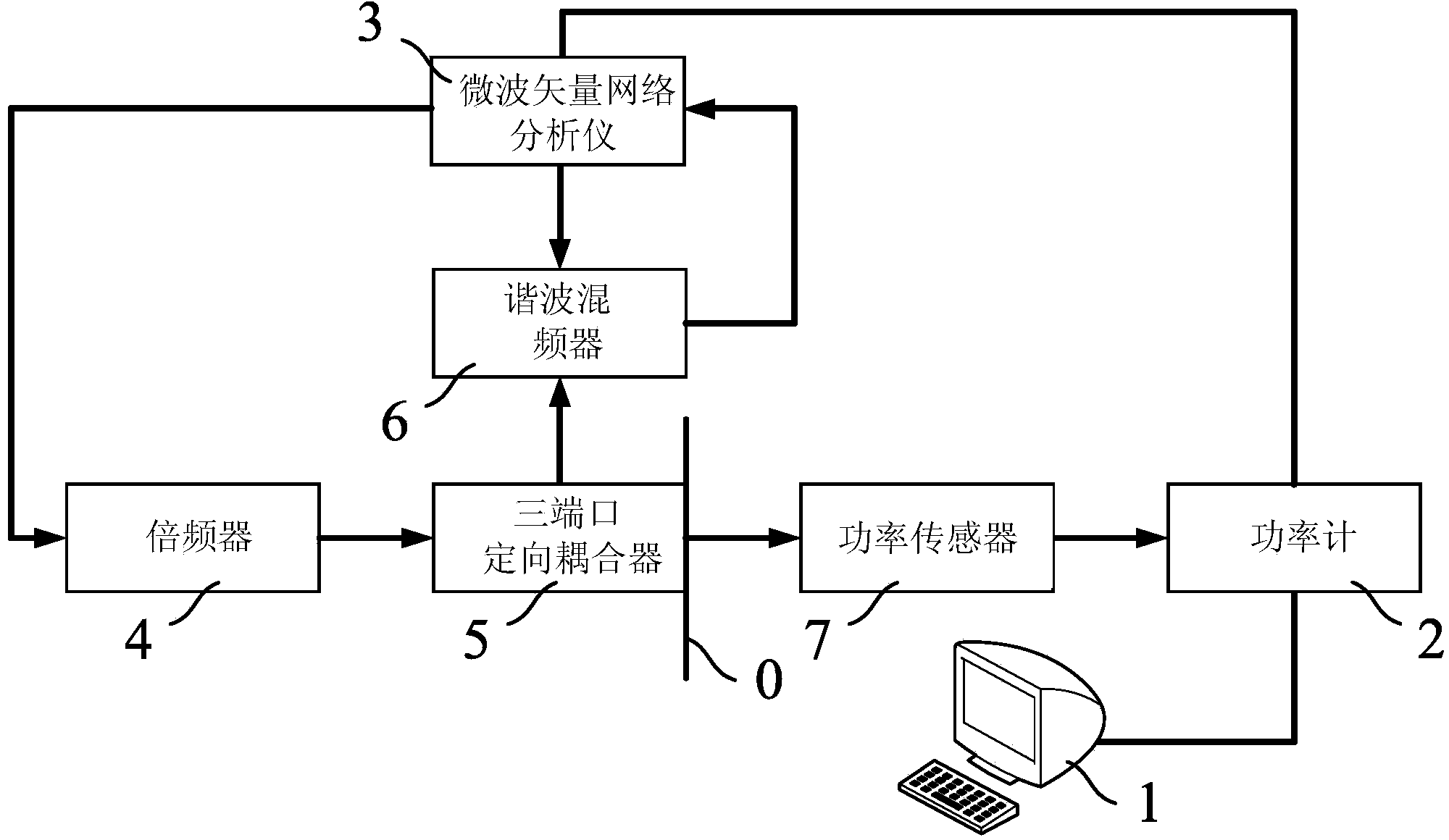

Embodiment 1

[0067] The power calibration test system of the present invention can work in any frequency band, and only need to select the corresponding frequency band for each module. In this embodiment, the working frequency band is set to the millimeter wave frequency band, that is, the frequency band is set to 30GHZ-300GHZ . Therefore, if Figure 4 As shown, in order to match the working frequency band, the frequency multiplier 4 is a millimeter wave frequency multiplier 41, the three-port directional coupler 5 is a millimeter wave three-port directional coupler 51, and the harmonic mixer 6 is a millimeter wave The harmonic wave mixer 61 and the power sensor 7 are millimeter wave power sensors 71 , and their connection relationship is consistent with that of the power calibration test system described above, which will not be repeated here.

[0068] The working principle of the above millimeter wave power calibration test system is as follows:

[0069] First, in the system setting de...

Embodiment 2

[0072] The present invention provides a power calibration measurement method, the power calibration measurement method at least includes:

[0073] First, build the power calibration test system described above, and use the real-time closed-loop calibration test program set in the system setting device 1 to set the target power and target frequency band.

[0074] In this embodiment, the working frequency band is set as the W band, and the frequency of the W band is 75GHZ~110GHZ. The connection relationship of the hardware part of the W band power calibration test system is basically the same as that of the above power calibration test system. The frequency converter 4 is selected as the W-band sixth frequency multiplier 42, the three-port directional coupler 5 is selected as the W-band three-port directional coupler 52, and the harmonic mixer 6 is selected as the W-band eighth harmonic mixer 62, The power sensor 7 is selected as a W-band power sensor 72 .

[0075] Then, detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com