Reluctance Motor

A reluctance motor, inductance technology, applied in electric components, synchronous generators, synchronous motors for single-phase current, etc., can solve the problem of difficult to obtain large torque, can not expect high-efficiency drive (efficiency, etc., to achieve high-efficiency Self-excitation function, the effect of avoiding the reduction of the reluctance torque and preventing the self-excitation from being blocked

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

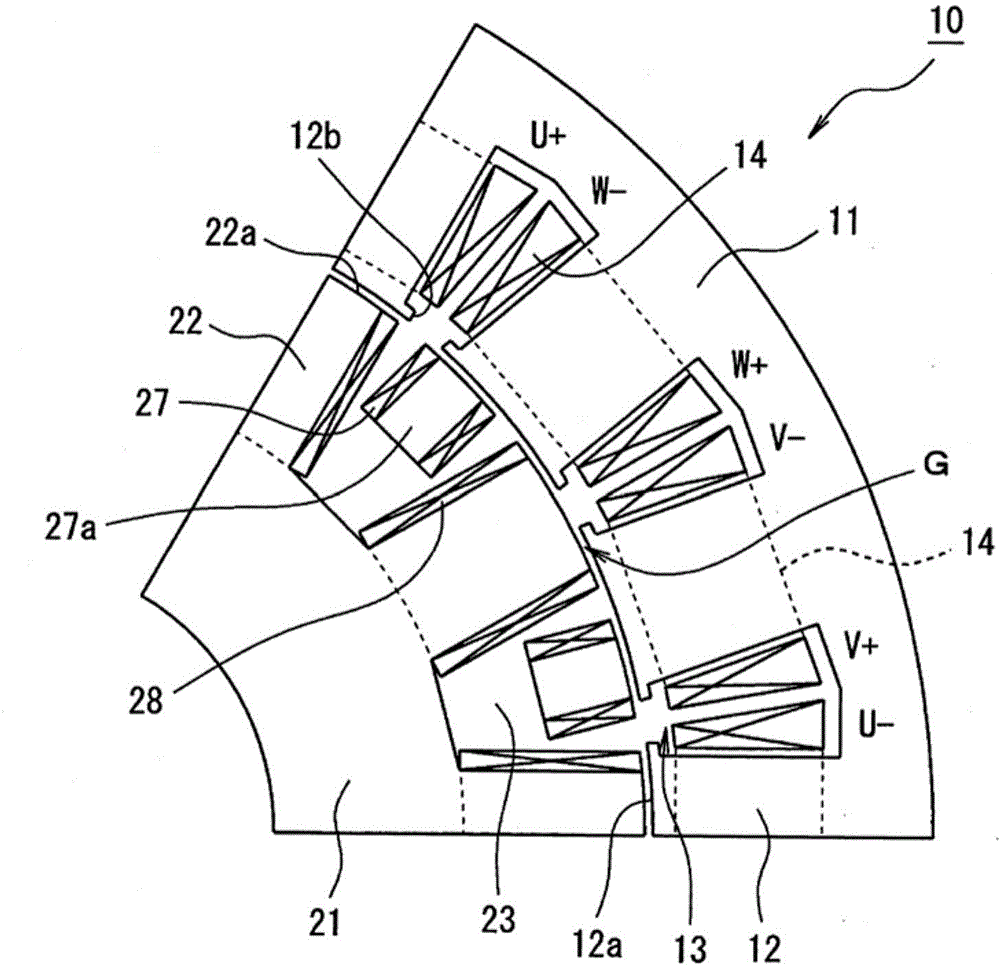

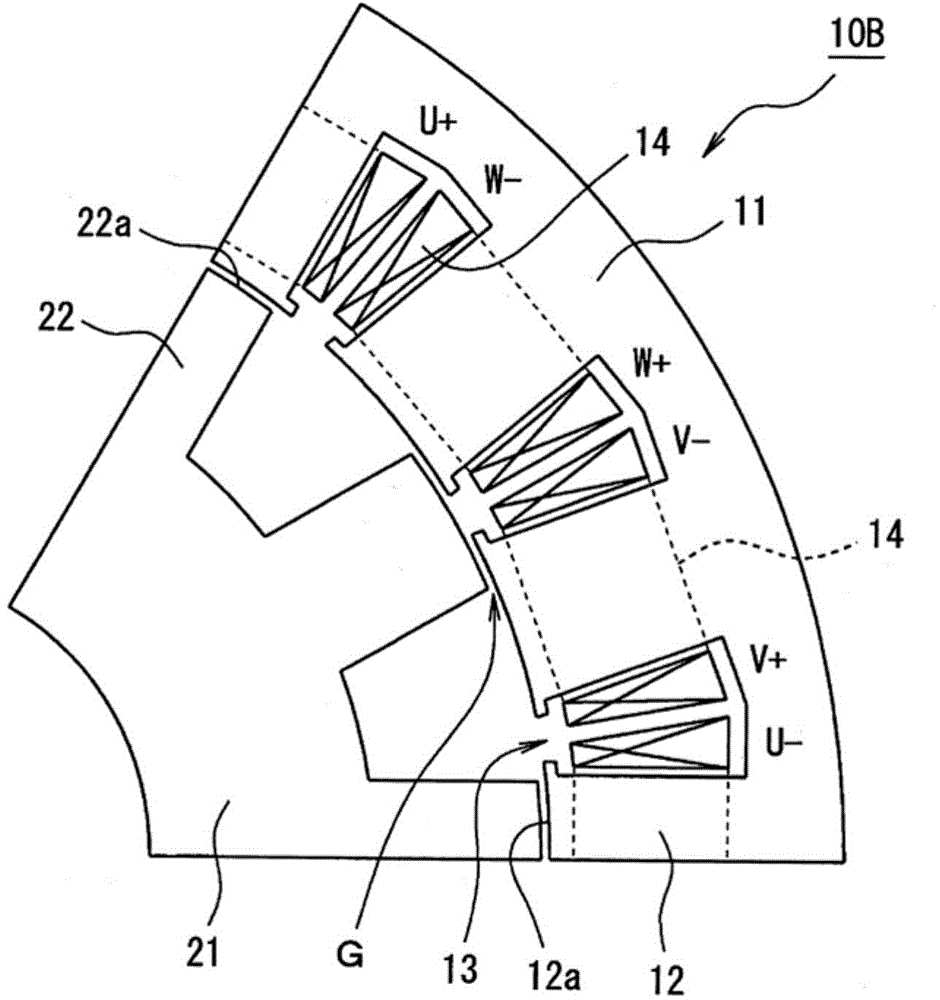

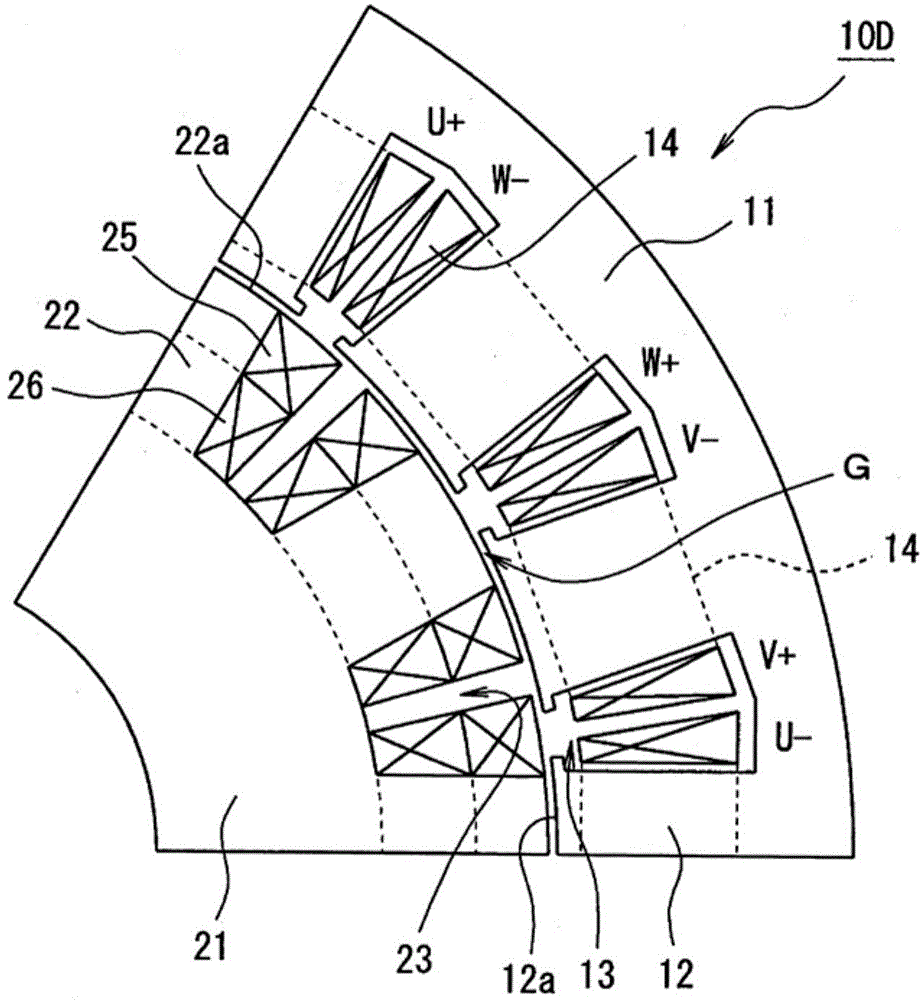

[0058] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. Figure 1 to Figure 21 is a diagram for explaining an embodiment of a reluctance motor according to the present invention. Figure 1 to Figure 3 is a radial cross-section of a reluctance motor, shown corresponding to a mechanical angle of 60° around its axis, respectively. This reluctance motor is manufactured to have a structure in which portions shown corresponding to a mechanical angle of 60° are periodically repeated in the circumferential direction.

[0059] exist figure 1 , the reluctance motor 10 has figure 2 The reluctance motor 10B of the basic structure shown in is based on, and employs a reluctance motor capable of solving image 3 The inherent problems of the reluctance motor 10D and the problems created by the reluctance motor 10B are shown in Fig. For example, the reluctance motor 10 has appropriate performance when mounted on a vehicle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com