Flotation column system and method for sorting high-concentration pulp

A flotation column and high-concentration technology, applied in flotation, solid separation, etc., can solve the problems of limited processing capacity of multi-product flotation columns, re-election of unsorted ore pulp, tailing coal leakage during separation, etc. , to achieve the effect of avoiding excessive processing of ore pulp, reducing coal running, and avoiding mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings:

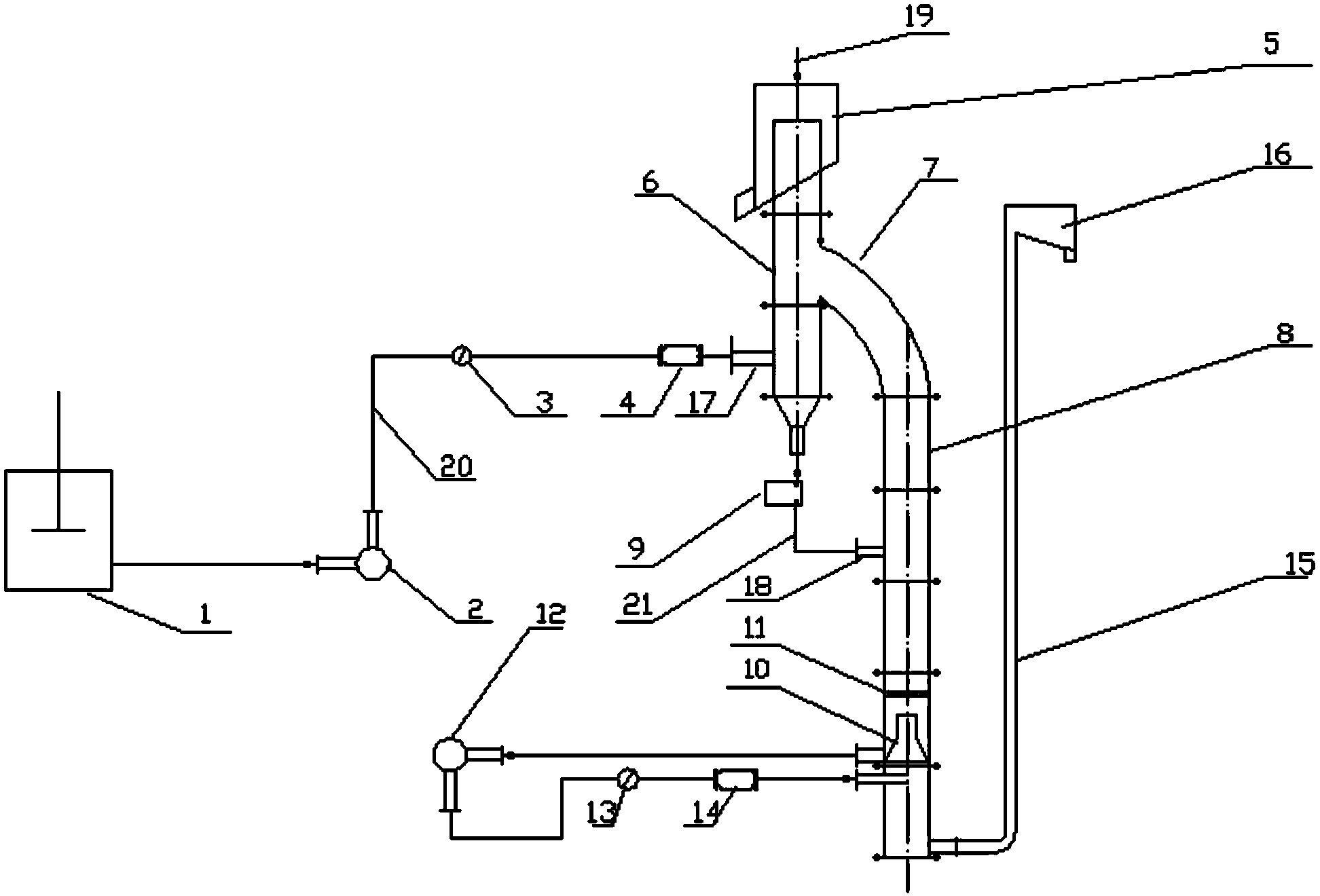

[0020] Such as figure 1 As shown, the flotation column system for separating high-concentration slurry of the present invention is mainly composed of an upper flotation column 6, a lower flotation column 8, a peristaltic pump 9, a feeding device, and a foaming device. The feeding device Including a slurry mixer 1, a feeding pump 2, an upper pressure gauge 3 and an upper bubble generator 4, which are connected in sequence via a feed pipe 20. The feed is connected to the feed pump 2, the pressure gauge 3, and the bubble generator 4 from the slurry agitator 1 in sequence, and then is connected in series with the upper flotation column 6. The structure of the lower flotation column 8 is a cyclone microbubble flotation column. The flow stabilizing plate 11 and a cone 10 are successively arranged from the lower flotation column inlet 18 to the bottom. The cone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com