Preparation method and application of self-activated persulfate oxidized medicament

A technology of persulfate oxidation and persulfate, applied in the direction of oxidized water/sewage treatment, restoration of polluted soil, etc., can solve the problems of difficult molding, poor dispersion, uneven mixing, etc., to achieve good removal effect and safe operation and management. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

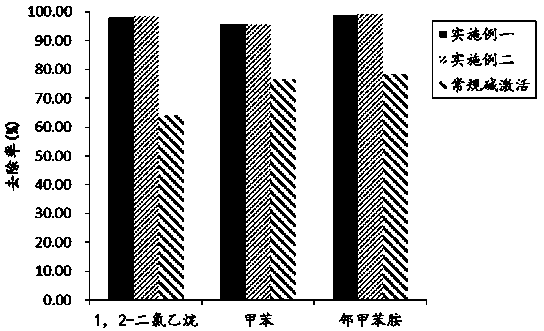

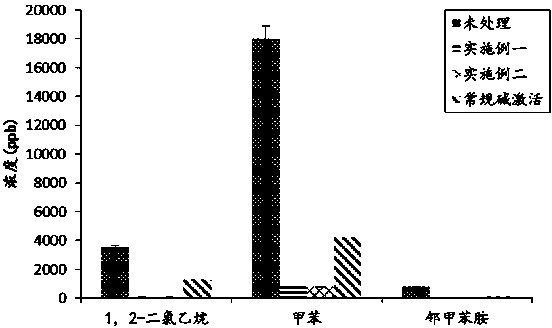

Embodiment 1

[0024] Mix 595 g of sodium persulfate and 180 g of calcium peroxide evenly, add 24 g of sodium hexadecylsulfonate as a dispersant, and 80 g of hydroxypropyl methylcellulose as a binder. After the mixed medicinal powder was stirred evenly, 77.5 g of deionized water was added and mixed evenly to make particles with a diameter of 3 mm, which were dried for 12 hours at a temperature of 30 °C and a vacuum of 0.1 kPa.

Embodiment 2

[0026] Mix 595 g of sodium persulfate and 180 g of calcium peroxide evenly, add 24 g of sodium hexadecylsulfonate as a dispersant, and 100 g of pregelatinized starch as a binder. After the mixed medicinal powder was stirred evenly, 77.5 g of deionized water was added and mixed evenly to make granules with a diameter of 30 mm, and dried at 20°C and a vacuum of 0.1 kPa for 12 hours.

Embodiment 3

[0028] Mix 135 g of potassium persulfate and 72 g of calcium peroxide evenly, add 2.07 g of sodium dodecylbenzenesulfonate as a dispersant, and 31 g of methylcellulose as a binder. After the mixed medicinal powder was stirred evenly, 10.35 g of water was added and mixed evenly to make granules with a diameter of 20 mm, and dried at 0°C and a vacuum of 0.1 kPa for 12 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com