Bamboo charcoal compound microbial fertilizer and production method thereof

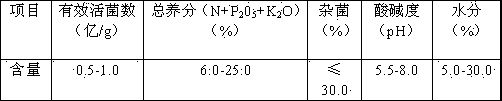

A technology of compound microorganisms and bamboo charcoal, applied in fertilizer mixture, fertilization device, application and other directions, can solve the problem of soil microorganisms not being replenished, and achieve the effects of improving soil aeration, agglomerate structure, and aeration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

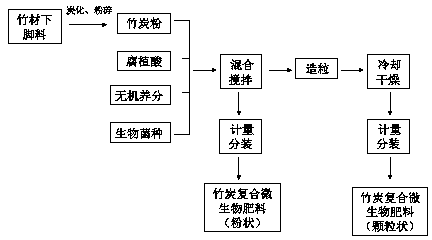

Method used

Image

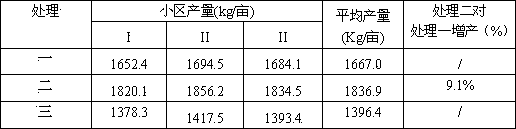

Examples

Embodiment 1

[0027] The selected bamboo or bamboo waste is cut off, dried naturally or artificially, then carbonized at high temperature, cooled and then pulverized by a pulverizer to obtain bamboo charcoal powder with a fineness of 80-100 mesh and a water content of 9% or less.

[0028] The obtained bamboo charcoal powder and humic acid, urea, ammonium dihydrogen phosphate, potassium sulfate, biological strains and binder were accurately proportioned according to the raw material ratio in Table 1. The mixture is thoroughly mixed by a mixer, and granulated by a granulator to prepare granular bamboo charcoal composite microbial fertilizer. The biological strain is Bacillus subtilis.

[0029] raw material bamboo charcoal powder humic acid urea Ammonium dihydrogen phosphate potassium sulfate Biological strain Attapulgite powder Proportion (kg) 280 487 40 30 60 3 100

Embodiment 2

[0031] Except following process, other is as embodiment 1. The biological strain is Bacillus lateralosporus.

[0032] The obtained bamboo charcoal powder and humic acid, urea, ammonium dihydrogen phosphate, potassium sulfate, biological strains and binder are accurately proportioned according to the raw material ratio in Table 2. The powdery bamboo charcoal composite microbial fertilizer is prepared through stirring and fully mixing by a mixer.

[0033] raw material bamboo charcoal powder humic acid urea Ammonium dihydrogen phosphate potassium sulfate Biological strain Proportion (kg) 200 475 155 67 100 3

Embodiment 3

[0035] Except following process, other is as embodiment 1.

[0036] The obtained bamboo charcoal powder and humic acid, urea, ammonium dihydrogen phosphate, potassium sulfate, biological strains and binder are accurately dosed according to the raw material ratio in Table 4. The biological strains in Table 4 are mixed strains of Azotobacter rufica, Bacillus megaterium and Bacillus colloidus in a mass ratio of 1:1:1. The powdery bamboo charcoal composite microbial fertilizer is prepared through stirring and fully mixing by a mixer.

[0037] raw material bamboo charcoal powder humic acid urea Ammonium dihydrogen phosphate potassium sulfate Biological strain Proportion (kg) 180 363 220 112 100 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com